A kind of imitation plum-shaped micro-channel heat sink cold plate and its cooling device

A plum blossom petal-shaped micro and micro channel technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem that the micro-channel heat dissipation structure cannot solve the heat dissipation demand, etc., to reduce the difference in fluid temperature, temperature The effect of uniform distribution and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

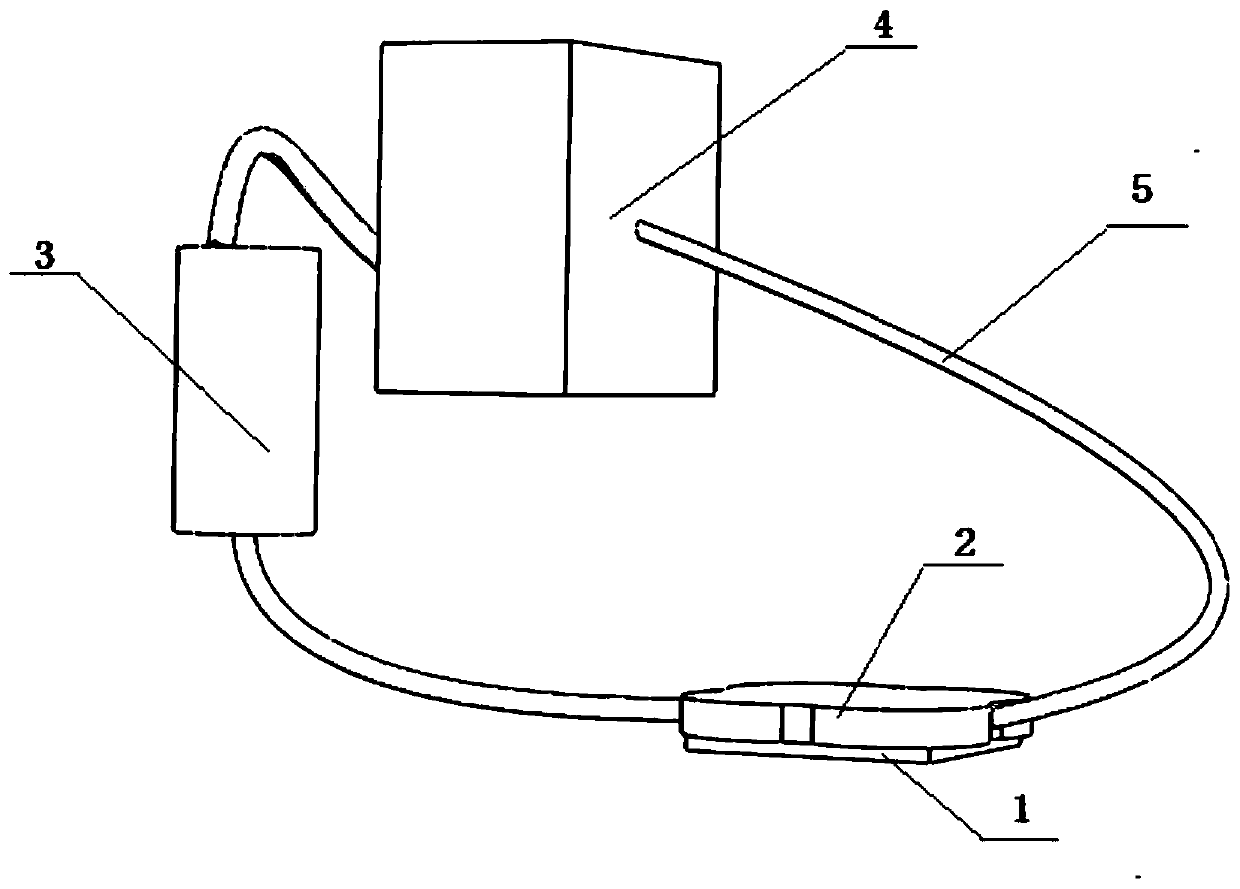

[0025] Such as figure 1 As shown, the quincunx-shaped microchannel structure heat dissipation cooling device related to the present invention includes four parts: a quincunx-shaped microchannel heat sink cold plate 2, a pulsating pump 3, a circulating liquid cooler 4 and a pipeline 5 connecting them.

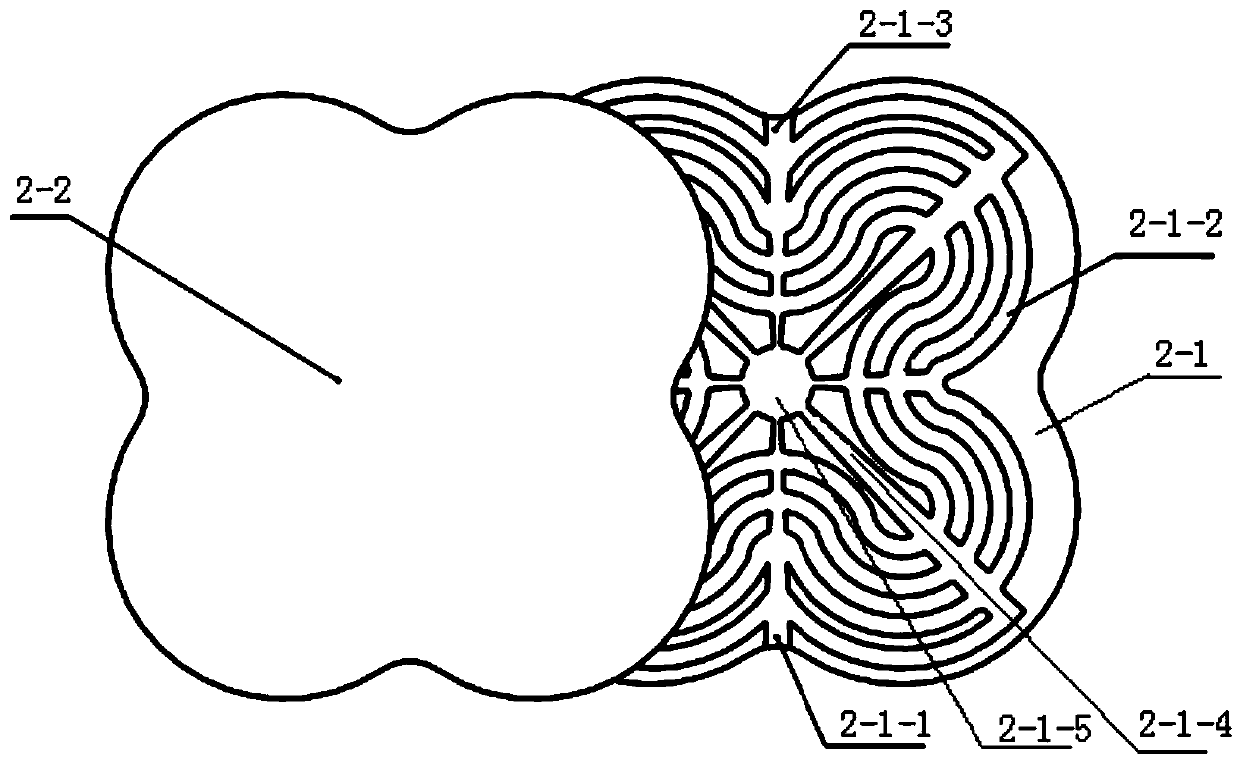

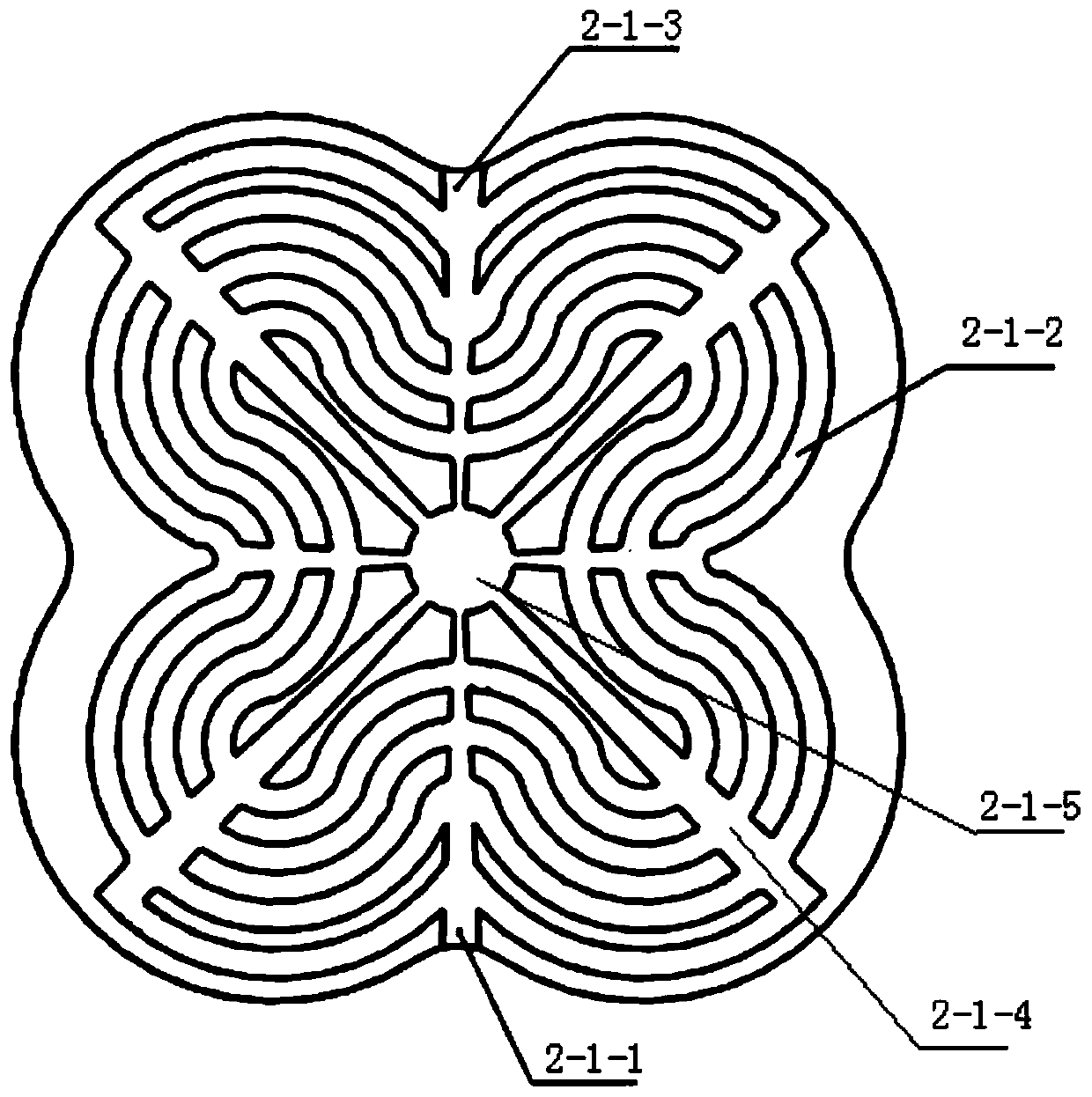

[0026] Such as figure 2 and image 3 As shown, the imitation quincunx-shaped micro-channel heat sink cold plate 2 includes a heat sink cover plate 2-2 and a micro-channel heat sink 2-1 that are closed up and down and are hermetically connected. The micro-channel heat sink 2-1 is provided with four A pair of mutually symmetrical plum-blossom-shaped microchannels, the plum-blossom-shaped microchannels are provided with several imitation plum-blossom flow channels 2-1-2 from the outside to the inside, and the corresponding imitation plum-blossom flow channels after the four plum-blossom petal-shaped microchannels are combined Road 2-1-2 is connected and forms four protrusions an...

Embodiment 2

[0032] Applied to CPU chip heat dissipation, the heat generated by the CPU chip is absorbed by the graphene coating through heat conduction and transferred to the micro-channel heat sink cold plate, and then the heat is absorbed by the cooling liquid flowing through the micro-channel heat sink cold plate through the connection of the micro-channel heat sink The cooling plate and the pipeline of the circulating liquid cooler are brought into the circulating liquid cooler for cooling, and finally the cooling liquid is returned to the pulsating pump through the pipeline connecting the pulsating pump and the circulating liquid cooler, forming a closed liquid cooling circulation system.

Embodiment 3

[0034] This embodiment provides a heat dissipation scheme for dealing with the case where any two heat sources are adjacent to each other. A plum blossom-shaped LED module is divided into upper and lower LED heat sources. The plum-shaped micro-channel heat sink cold plate is sandwiched between the two LED heat sources. The two LED heat sources are fixed by bolts, and the bolts pass through the plum-shaped micro-channel heat sink cold plate. The other two recesses of the liquid injection port and the liquid outlet are removed in the structure. The micro-channel cooling device of this embodiment is mainly composed of four parts: a quincunx-like micro-channel heat sink cold plate, a pulsation pump, a circulating liquid cooler, and pipes connecting them. The micro-channel cooling device is evacuated from the liquid injection port and injected with a certain volume of water or other cooling fluids, and then sealed. The pulsating flow generated by the pulsating pump enters the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com