Micro pressure sensor

A micro pressure sensor and sensing medium technology, applied in the field of sensors, can solve the problems of poor measurement accuracy, pressure sensor intolerant to bending, insufficient sensitivity, etc., and achieve the effects of stable detection data, good durability and increasing the number of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

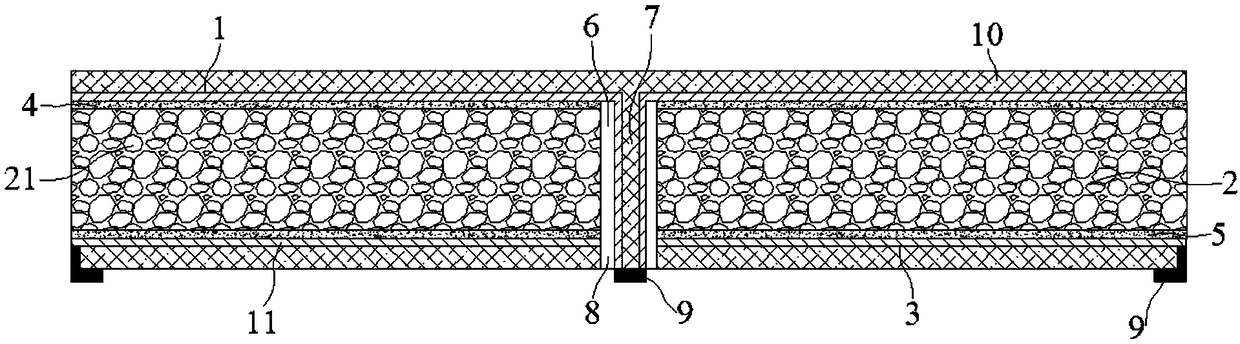

[0029] Embodiment 1~4: a kind of micro pressure sensor, comprise upper conductive electrode 1, sensing medium layer 2, lower conductive electrode 3, described upper conductive electrode 1, lower conductive electrode 3 are respectively connected with sensing medium layer 2 upper surface and The lower surface is connected by a first conductive adhesive layer 4 and a second conductive adhesive layer 5, and the sensing medium layer 2 includes a foamed polyurethane body 21 and an induction coating layer filled in the surface and pores of the foamed polyurethane body 21 Composition, the induction coating layer consists of the following components, as shown in Table 1:

[0030] Table 1

[0031]

Example 1

Example 2

Example 3

Example 4

100 parts of silver nano conductor aqueous dispersion

100 copies

100 copies

100 copies

100 copies

3~5 parts of water-based acrylic resin

4 parts

5 copies

4.2 parts

3 copies

Alc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com