A steel bridge deck pavement layer and a preparation method thereof

A technology of pavement layer and steel bridge deck, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as insufficient anti-skid performance and hidden dangers of vehicle safety, avoid various uncertain factors, improve anti-skid performance, The effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

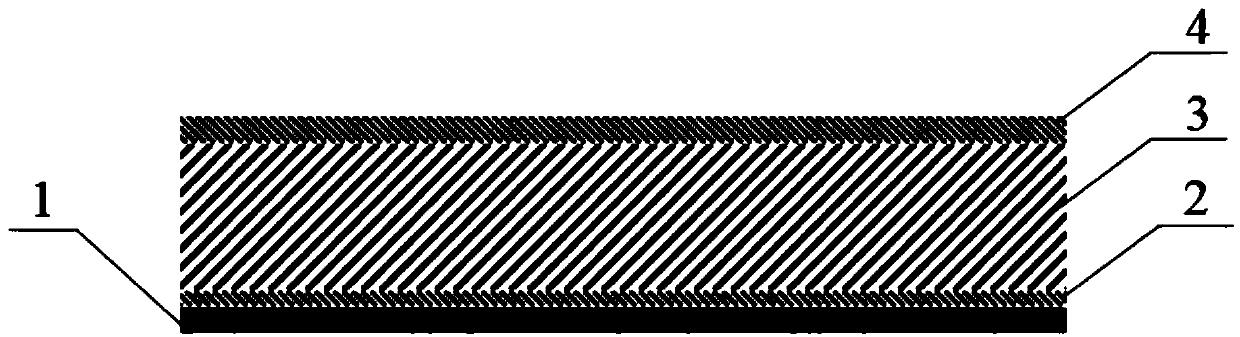

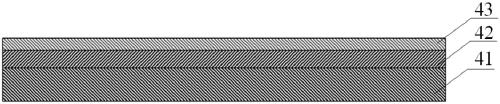

[0041] Present embodiment 1 provides a kind of steel bridge deck pavement, its structure is as follows figure 1 As shown, an adhesive layer 2 , a composite material layer 3 and an anti-skid and wear-resistant layer 4 are successively laid on the steel bridge deck 1 from bottom to top. In order to ensure good pavement performance, the thickness of the bonding layer 2 is 0.4 mm, and the thickness of the composite material layer 3 is between 1 and 10 cm. The specific thickness of the composite material layer 3 can be determined according to the thickness requirements of the steel bridge deck pavement layer , the thickness of the anti-skid and wear-resistant layer 4 is between 2 and 5mm, and the specific thickness of the anti-skid and wear-resistant layer 4 is determined by the single particle size of the selected aggregate. In layer spreading construction, the thickness of the anti-skid and wear-resistant layer is 5mm, and when aggregates with a single particle size of 2-3mm are ...

Embodiment 2

[0044] This embodiment provides a kind of steel bridge deck pavement, its structure and the thickness of each layer are identical with embodiment 1, and its composition raw material is specifically:

[0045] The bonding layer, in parts by weight, its raw materials include the following components:

[0046] 10 parts of bisphenol A epoxy resin; 10 parts of polyurethane; 8 parts of polycarbonate; 1.2 parts of accelerator; 1 part of water reducing agent; 0.8 parts of defoamer; 0.8 parts of coupling agent; 5 parts of curing agent.

[0047] Composite material layer, by weight parts, its raw material includes the following components:

[0048] 100 parts of cement; 240 parts of fly ash; 160 parts of slag; 155 parts of river sand; 12 parts of polyvinyl alcohol fiber; 150 parts of water; 1.2 parts of water reducer, 44 parts of viscosity regulator.

[0049] The anti-slip and wear-resistant layer is composed of emulsion and basalt gravel with a single particle size of 3-5mm, mixed and so...

Embodiment 3

[0064] This embodiment provides a kind of steel bridge deck pavement, its structure and the thickness of each layer are identical with embodiment 1, and its composition raw material is specifically:

[0065] The bonding layer, in parts by weight, its raw materials include the following components:

[0066] 8 parts of bisphenol A epoxy resin; 12 parts of polyurethane; 5 parts of polycarbonate; 0.5 parts of accelerator; 0.5 parts of water reducing agent; 0.6 parts of defoaming agent; 0.6 parts of coupling agent;

[0067] Composite material layer, by weight parts, its raw material includes the following components:

[0068] 100 parts of cement; 280 parts of fly ash; 120 parts of slag; 150 parts of river sand; 10 parts of polyvinyl alcohol fiber; 160 parts of water;

[0069] The anti-slip and wear-resistant layer is composed of emulsion and basalt gravel with a single particle size of 3-5 mm, mixed and solidified, wherein the added mass of basalt accounts for 50% of the anti-slip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com