Laser additive manufacturing method for La2O3/(Cu, Ni) functionally graded composites

A gradient function, laser additive technology, applied in additive manufacturing, additive processing, energy efficiency improvement, etc., can solve the problems of increasing material preparation cycle and energy consumption, and achieve the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

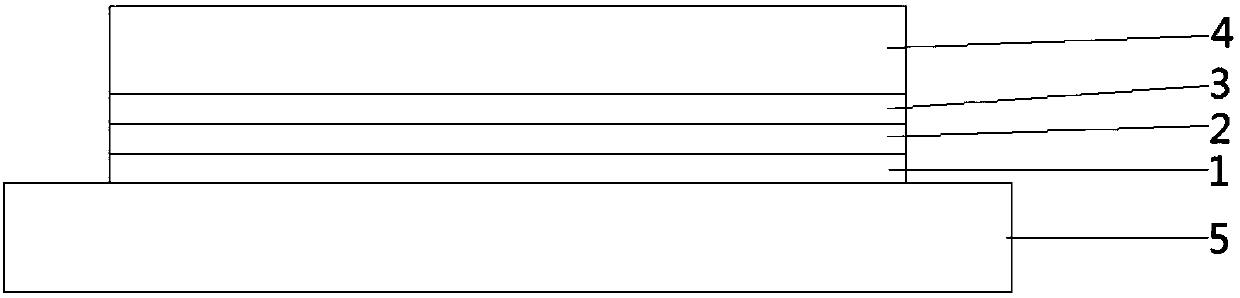

[0034] A kind of laser additive manufacturing La 2 o 3 / (Cu, Ni) the method for gradient function composite material, its step is as follows:

[0035] S1, the preparation of raw material powder;

[0036] La 2 o 3 The particle size of the powder is 2-10 μm, and the purity is 99.4%; the particle size of the Cu powder is 50-150 μm, and the purity is 99.9%; the particle size of the Ni45 powder is 50-150 μm, and the purity is 99.9%; the ratio of various powders is shown in Table 1.

[0037] Table 1 Various powder ratios and corresponding layer sequences

[0038]

[0039] Prepare 4 kinds of raw material powders according to the proportions in Table 1, mix the powders by ball milling, and put them into a drying oven. Drying temperature: 110°C, time: 90min, remove the moisture in the powders, and prepare 4 kinds of raw material powders.

[0040] S2, pretreatment of Cu substrate;

[0041] The selected Cu substrate size is 150×50×15mm 3 . Use 240# sandpaper to polish the surf...

Embodiment 2

[0053] A kind of laser additive manufacturing La 2 o 3 / (Cu, Ni) the method for gradient function composite material, its step is as follows

[0054] S1, the preparation of raw material powder;

[0055] La 2 o 3 The particle size of the powder is 2-10 μm, and the purity is 99.4%; the particle size of the Cu powder is 50-150 μm, and the purity is 99.9%; the particle size of the N545 powder is 50-150 μm, and the purity is 99.9%; the ratio of various powders is shown in Table 2.

[0056] Table 2 Various powder ratios and corresponding layer sequences

[0057]

[0058] Prepare 5 kinds of raw material powders according to the proportions in Table 2, mix them by ball milling, and put them into a drying oven. Drying temperature: 110°C, time: 90min, remove the moisture in the powders, and prepare 5 kinds of raw material powders.

[0059] S2, pretreatment of Cu substrate;

[0060] The selected Cu substrate size is 150×50×15mm 3 . Use 240# sandpaper to polish the surface of t...

Embodiment 3

[0070] A kind of laser additive manufacturing La 2 o 3 / (Cu, Ni) the method for gradient function composite material, its step is as follows

[0071] S1, the preparation of raw material powder;

[0072] La 2 o 3 The particle size of the powder is 2-10 μm, and the purity is 99.4%; the particle size of the Cu powder is 50-150 μm, and the purity is 99.9%; the particle size of the Ni45 powder is 50-150 μm, and the purity is 99.9%; the ratio of various powders is shown in Table 3.

[0073] Table 3 The sequence corresponding to various powder ratios

[0074]

[0075]

[0076] Prepare 4 kinds of raw material powders according to the proportions in Table 3, mix them by ball milling, and dry them in a drying oven at 110°C for 90 minutes to remove moisture from the powders; 4 kinds of raw material powders are prepared

[0077] S2, pretreatment of Cu substrate;

[0078] The selected Cu substrate size is 150×50×15mm 3 . Use 240# sandpaper to polish the surface of the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com