Preparation method of degradable chemical fertilizer sustained-release material

A slow-release material and fertilizer technology, which is applied in the field of preparation of degradable fertilizer slow-release materials, can solve the problems of poor fertilizer slow-release control ability, low fertilizer utilization rate, easy to cause pollution, etc., and achieve the effect of strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

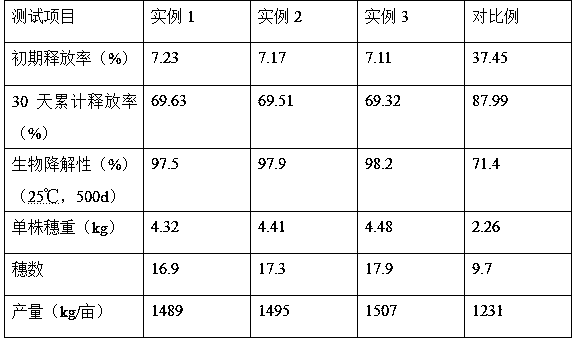

Examples

Embodiment Construction

[0025] Collect the peat and put it into the carbonization furnace, heat it to 150-200℃, keep the temperature for 30-35min, and then place it in a ball mill for 40-50min, pass a 400-mesh standard sieve to obtain porous charcoal powder, and ignite the soybean straw to obtain straw Ash, then mix porous carbon powder, straw ash, and water in a mass ratio of 2:1:3, and place them in a homogenizer for 1-2 hours to obtain a slurry; put 2.0-2.5L of the above-mentioned slurry into the fermentation tank, After adding 30-40g glucose, 400-500mL biogas slurry with a solid mass content of 30%, 20-25g biochemical potassium fulvic acid and 60-70g potassium nitrate into the fermenter, seal the fermenter and keep it at a temperature of 40-45℃. In the greenhouse, heat preservation and fermentation for 8-10 days, take out the fermentation broth and put it in a water bath, add 70-80g urea, 200-300mL formaldehyde solution with a mass fraction of 37%, heat to 70-75℃, stir at constant temperature for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com