Method for achieving biochemical sludge resource treatment by culturing hermetia illucens

A biochemical sludge and treatment method technology, applied in the direction of biological sludge treatment, application, animal feed, etc., can solve the problems of treatment efficiency reduction, oxygen consumption, difficulties, etc., achieve resource utilization, solve environmental pollution problems, reduce The effect of large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

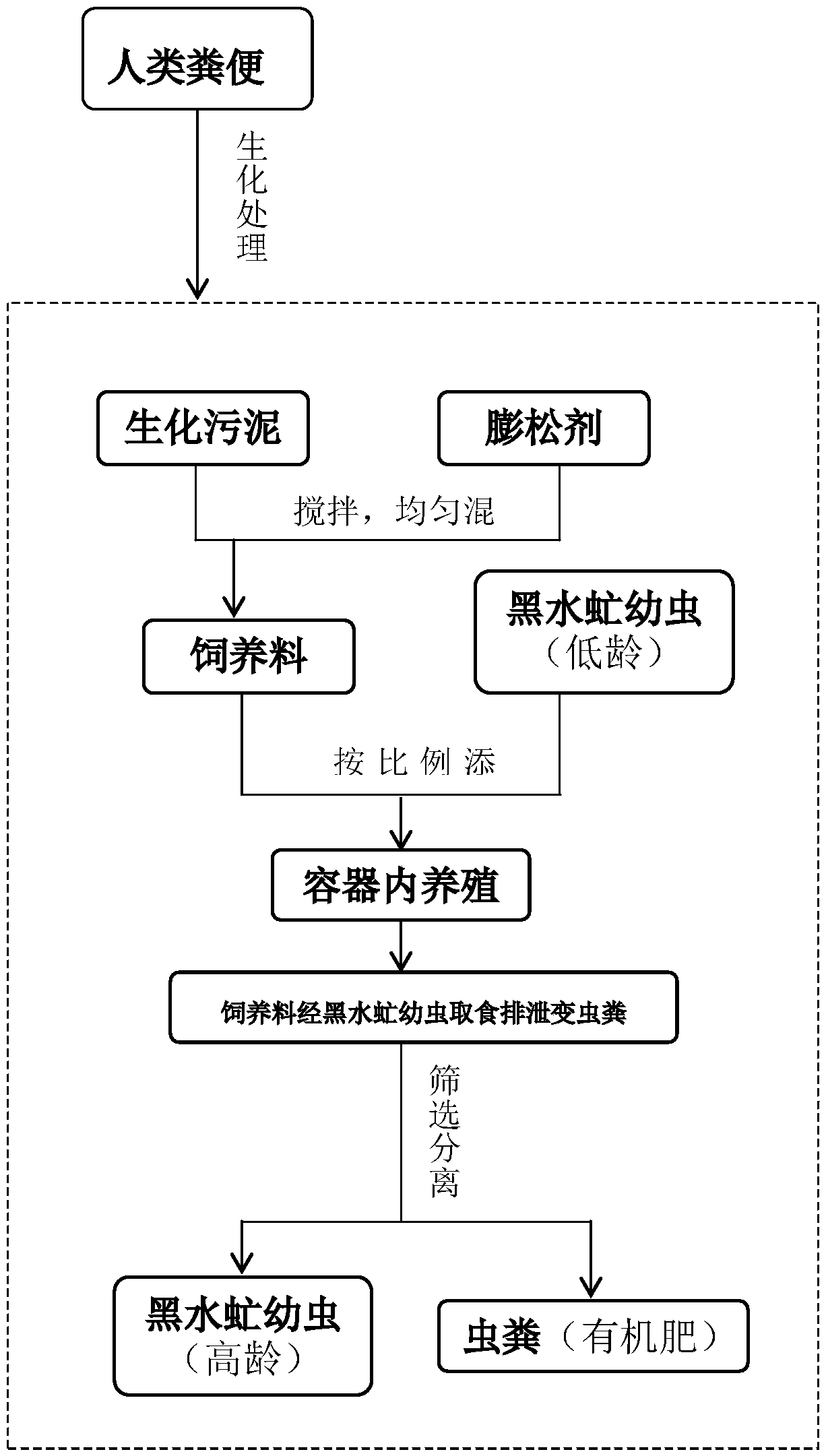

Method used

Image

Examples

Embodiment 1

[0020] 1. Take 1kg of biochemical sludge (water content 65%) and 0.20kg of wet rush granules (1-3mm in length) and stir them well every day and place them in a container to feed black soldier fly larvae. The black soldier fly larvae are made of kitchen waste Larvae (length greater than 0.5 cm) are hatched and fed with the slurry for three days. After feeding for 20 days, the larvae gradually age and enter the prepupa stage for screening and separation. The ambient temperature for breeding is 28°C, the air humidity is 60%RH, and the conditions of low light.

[0021] 2. Add sawdust to feed and black soldier fly larvae, stir evenly to reduce the humidity to 35% RH, then vibrate to separate organic fertilizer and black soldier fly larvae. 20kg of organic fertilizer and 2.5kg of black soldier fly larvae (prepupal state) can be obtained.

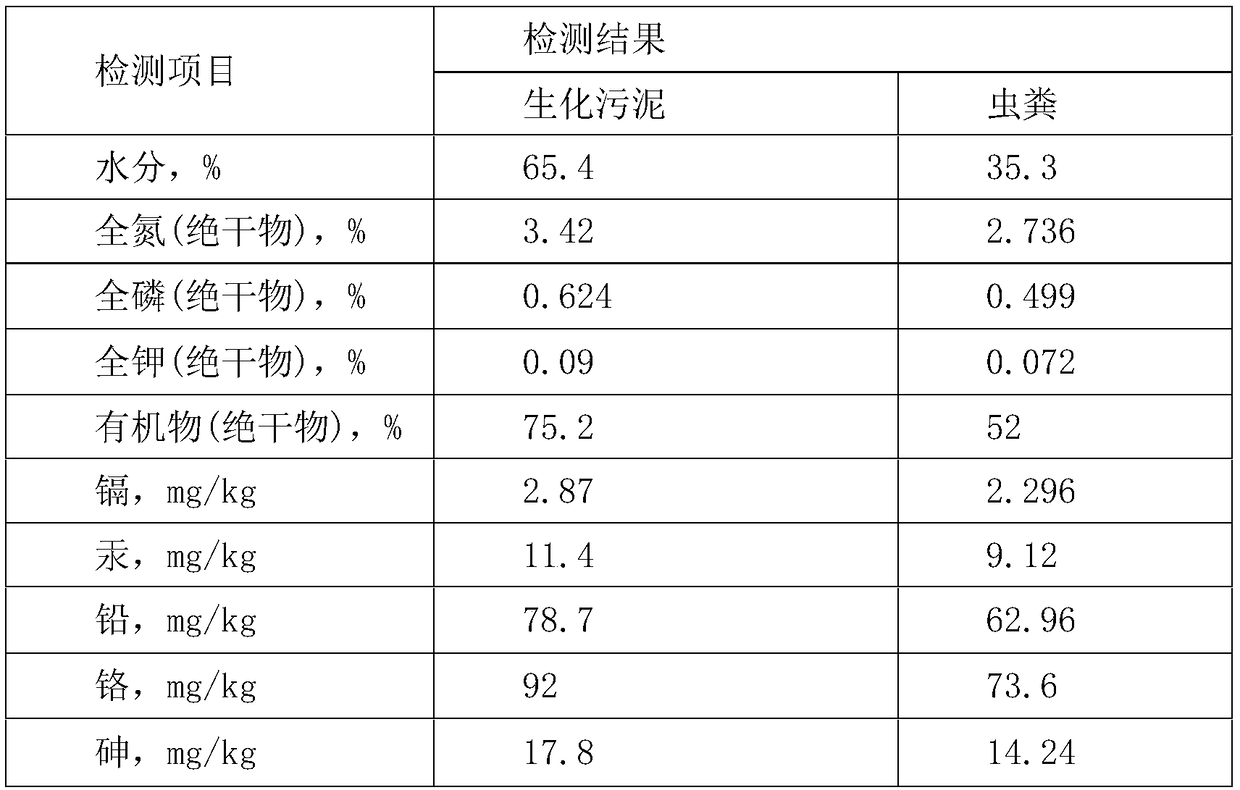

[0022] 3. The composition analysis comparison table of the separated organic fertilizer is as follows:

[0023] Table 1. Comparison table of de...

Embodiment 2

[0026] 1. Take 10kg of biochemical sludge (water content 60%) every day, 2.5kg of wet wheat bran is fully stirred and placed in a container to feed black soldier fly larvae. Black soldier fly larvae are larvae hatched and fed with pumpkin mud for three days (length greater than 0.5cm), after feeding for 20 days, the larvae gradually aged and entered the prepupa stage, and were screened and separated. The ambient temperature for breeding is 25°C, the air humidity is 70%RH, and the conditions of low light.

[0027] 2. Add sawdust to feed and black soldier fly larvae, stir evenly to reduce the humidity to 35% RH, then vibrate to separate organic fertilizer and black soldier fly larvae. 186kg of organic fertilizer and 23kg of black soldier fly larvae (prepupal state) can be obtained.

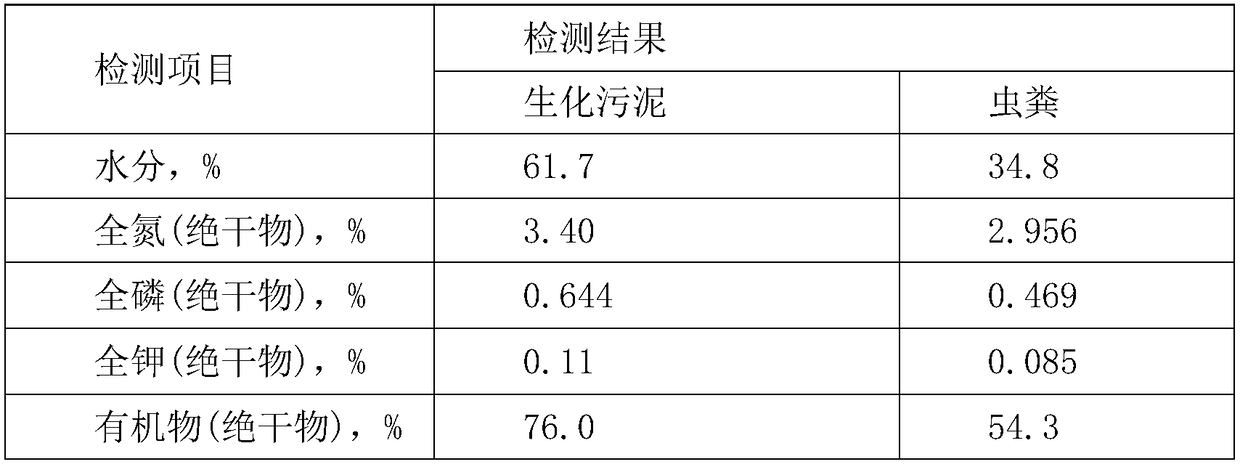

[0028] 3. The composition analysis comparison table of the separated organic fertilizer is as follows:

[0029] Table 2. Comparison table of detection items of biochemical sludge and insect droppi...

Embodiment 3

[0033] 1. Take 9kg of biochemical sludge (water content 70%) every day, 3kg of wet rice bran is fully stirred and placed in a container to feed black soldier fly larvae. Black soldier fly larvae are larvae hatched and fed with pumpkin mud for three days (length greater than 0.5 cm), after 10 days of feeding, the larvae gradually matured, and they were in the best collection period of protein feed, and they were screened and separated. The ambient temperature for breeding is 30°C, the air humidity is 70% RH, and the conditions of low light.

[0034] 2. Add sawdust to feed and black soldier fly larvae, stir evenly to reduce the humidity to 25% RH, then vibrate to separate the organic fertilizer and black soldier fly larvae. 103kg of organic fertilizer and 16kg of black soldier fly larvae can be obtained.

[0035] 3. The composition analysis comparison table of the separated organic fertilizer is as follows:

[0036] Table 3. Comparison table of detection items of biochemical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com