Pneumatic bottle cleaning device

A pneumatic and jet tube technology, which is applied in transportation and packaging, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as incomplete cleaning, affecting the normal use of equipment, and crushing difficult waste materials, so as to improve the cleaning effect and prevent The effect of bending damage and reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

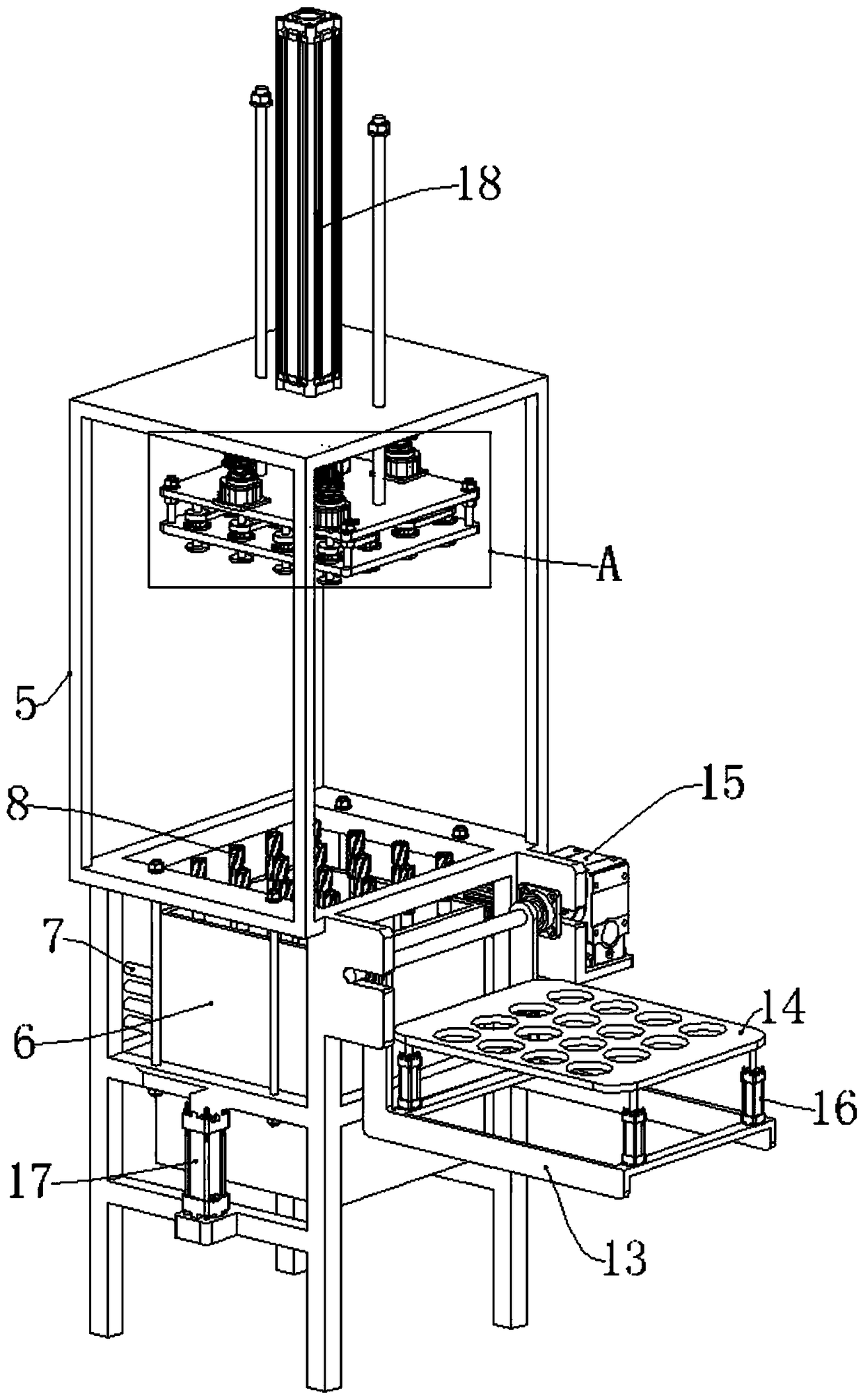

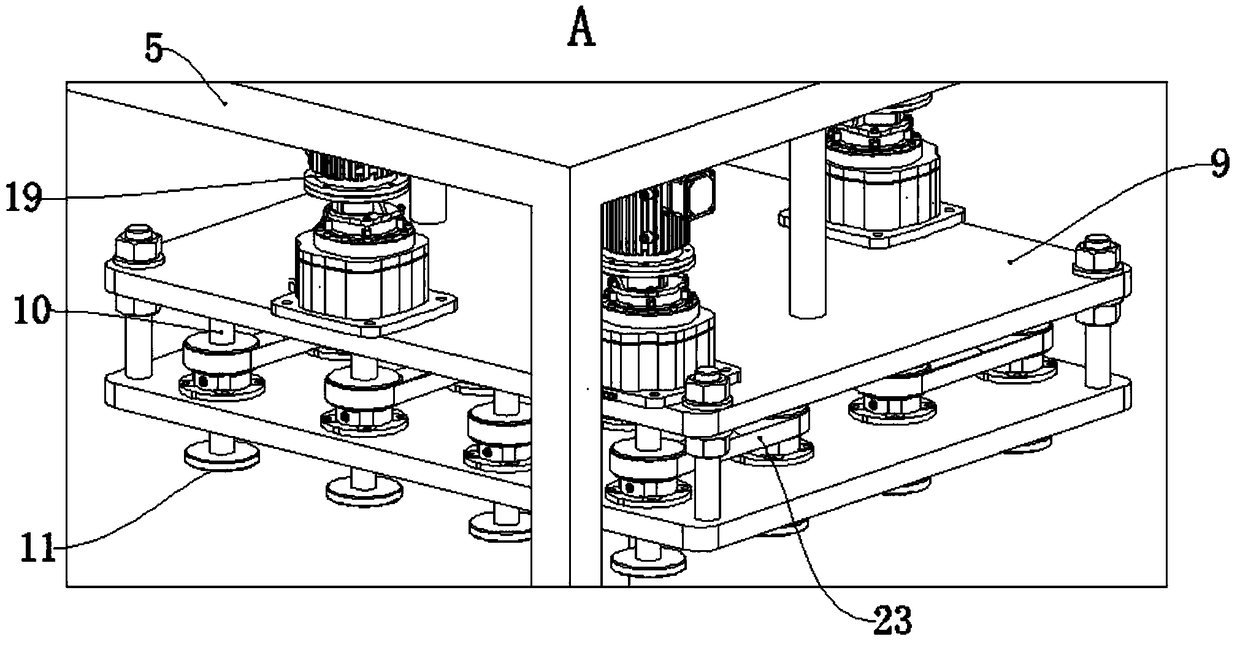

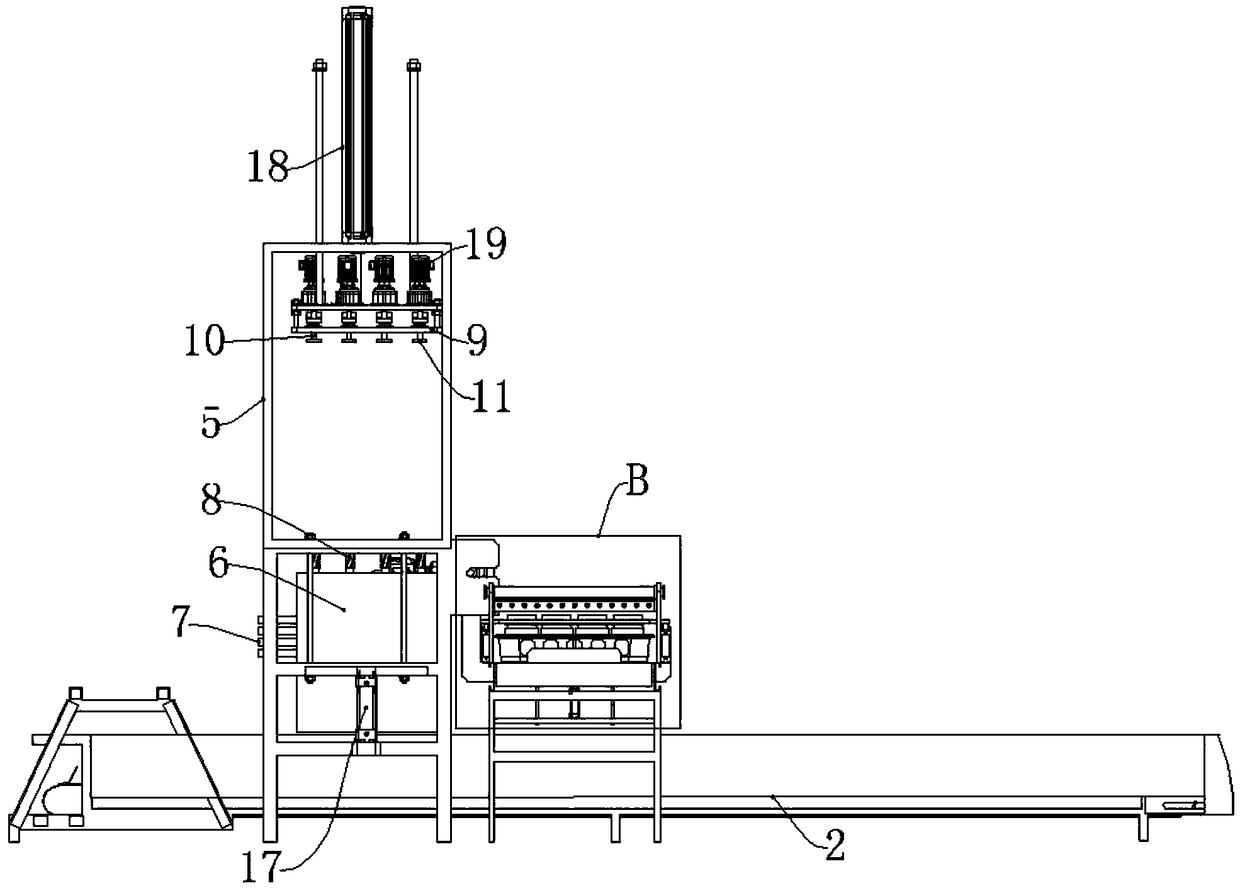

[0019] Figure 1 ~ Figure 3 Shown the pneumatic bottle clearing device of the present invention, this pneumatic bottle clearing device belongs to edible mushroom cultivation bottle and waste recovery device (as Figure 4 ~ Figure 8 As shown), the edible fungus cultivation bottle and waste recovery device include a cultivation bottle conveyor 1, a pneumatic bottle clearing device, a waste conveyor 2 and a cultivation bottle set.

[0020] The cultivation bottle conveyor 1 is located at one side of the pneumatic bottle clearing device, and the cultivation bottle conveyor 1 is a roller conveyor for conveying the cultivation bottle kit. The cultivation bottle conveyor 1 is provided with a blocking mechanism, which includes a baffle plate 21 and a baffle plate lifting cylinder 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com