Compression molding method for carbon fiber automotive front cover

A technology of carbon fiber and compression molding, which is applied in the field of rapid molding process of carbon fiber front hatch, which can solve the problems such as the direction of the carbon fiber texture on the outer surface cannot be disordered, the production line is put into the equipment site, the cost is increased, and the semi-finished product takes a long time to occupy the mold, etc., so as to avoid The fiber texture is disordered, the product shape is avoided, and the molding cycle is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

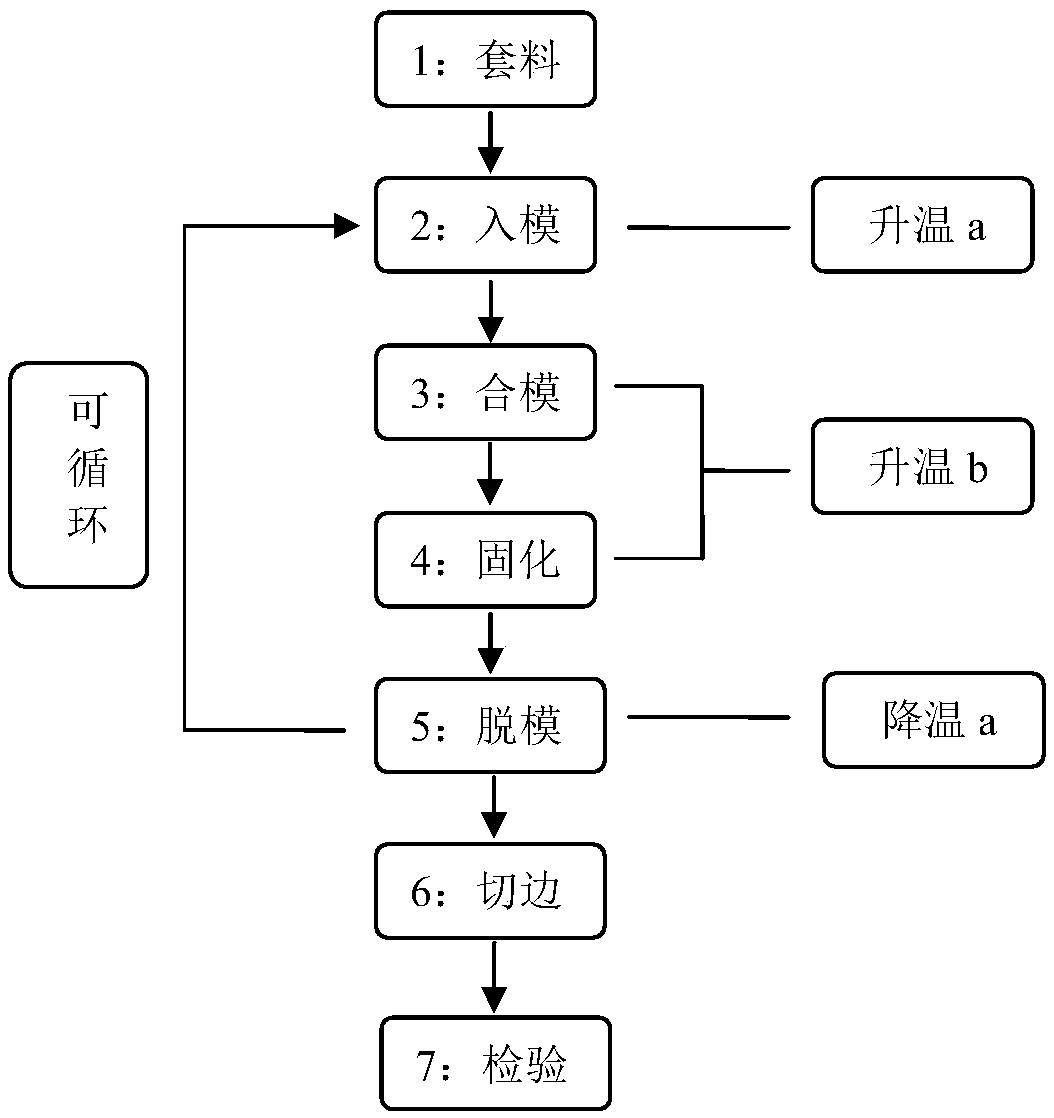

[0024] A carbon fiber automobile front hatch cover molding method of the present invention is applied on a molding production line of a certain automobile carbon fiber front hatch cover. The fast-curing carbon fiber prepreg is cured at a medium temperature of 130-150 ° C. The main equipment is a cutting machine (with automatic stripping) Prepreg upper / lower two-layer release paper function), press (with rapid heating / cooling function), forming mold, on the assembly line, the method of realizing the compression molding is as follows:

[0025] 1: Prepreg cutting: according to the designed shape of the front hatch cover, use a cutting machine to cut the required 4 layers of medium temperature curing carbon fiber prepreg (1 layer of 3K + 3 layers of 12K) in one piece. The 3K carbon fiber prepreg is The film layer is placed at the bottom;

[0026] 2. Mold entry: Put the cut prepreg (4 layers in total) directly into the molding mold that has been raised to a medium and low temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com