Anti-cracking ceramic lamp tube cutting equipment

A technology for cutting equipment and lamps, which is applied in stone processing equipment, work accessories, stone processing tools, etc., can solve problems such as affecting the processing quality of ceramic lamps, low processing efficiency of ceramic lamps, and inability to process ceramic lamps. , to avoid the loss of raw materials for ceramic lamp processing, the structure is simple, and the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

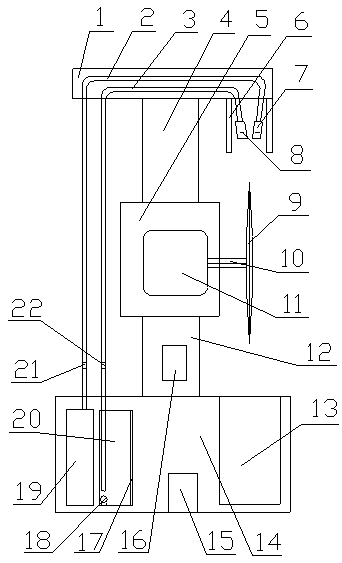

[0011] An anti-crack ceramic lamp tube cutting equipment, including a cover 1, a cold air pipe 2, a coolant pipe 3, a bracket 4, a drive motor seat 5, a shield 6, a cold air nozzle 7, a coolant nozzle 8, a cutting knife 9, a connecting Shaft 10, drive motor 11, base 12, waste liquid tank 13, equipment table body 14, controller 15, operation display 16, liquid pump 18, air cooler 19, coolant tank 20, solenoid valve 1 21 and solenoid valve 2 22 , the base 12 is arranged on the top of the equipment table body 14, the operation display 16 is arranged on the front of the base 12, the drive motor seat 5 is arranged on the top of the base 12, the drive motor 11 is arranged in the drive motor seat 5, and the bracket 4 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com