Device and method for continuously producing heat-insulating sandwich curtain wall plate

A technology of curtain wall panels and thermal insulation clips, applied in the direction of walls, other manufacturing equipment/tools, building components, etc., to achieve the effect of reducing labor cost input, reducing labor errors, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment, further illustrate the present invention.

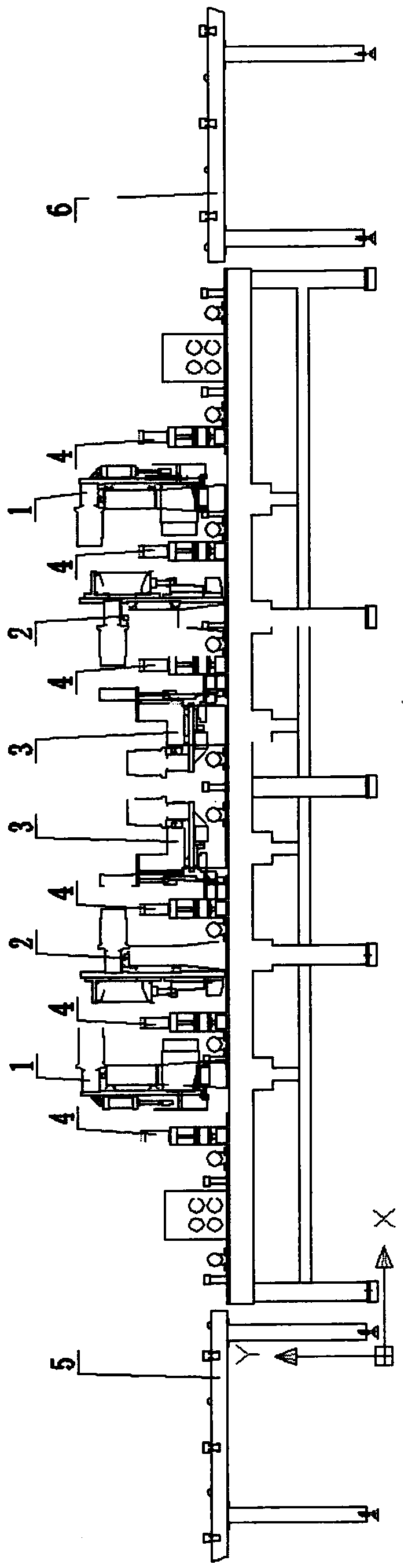

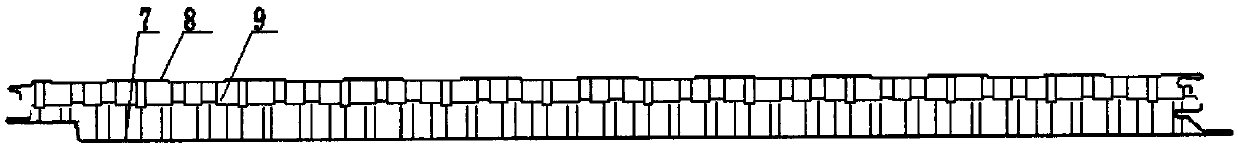

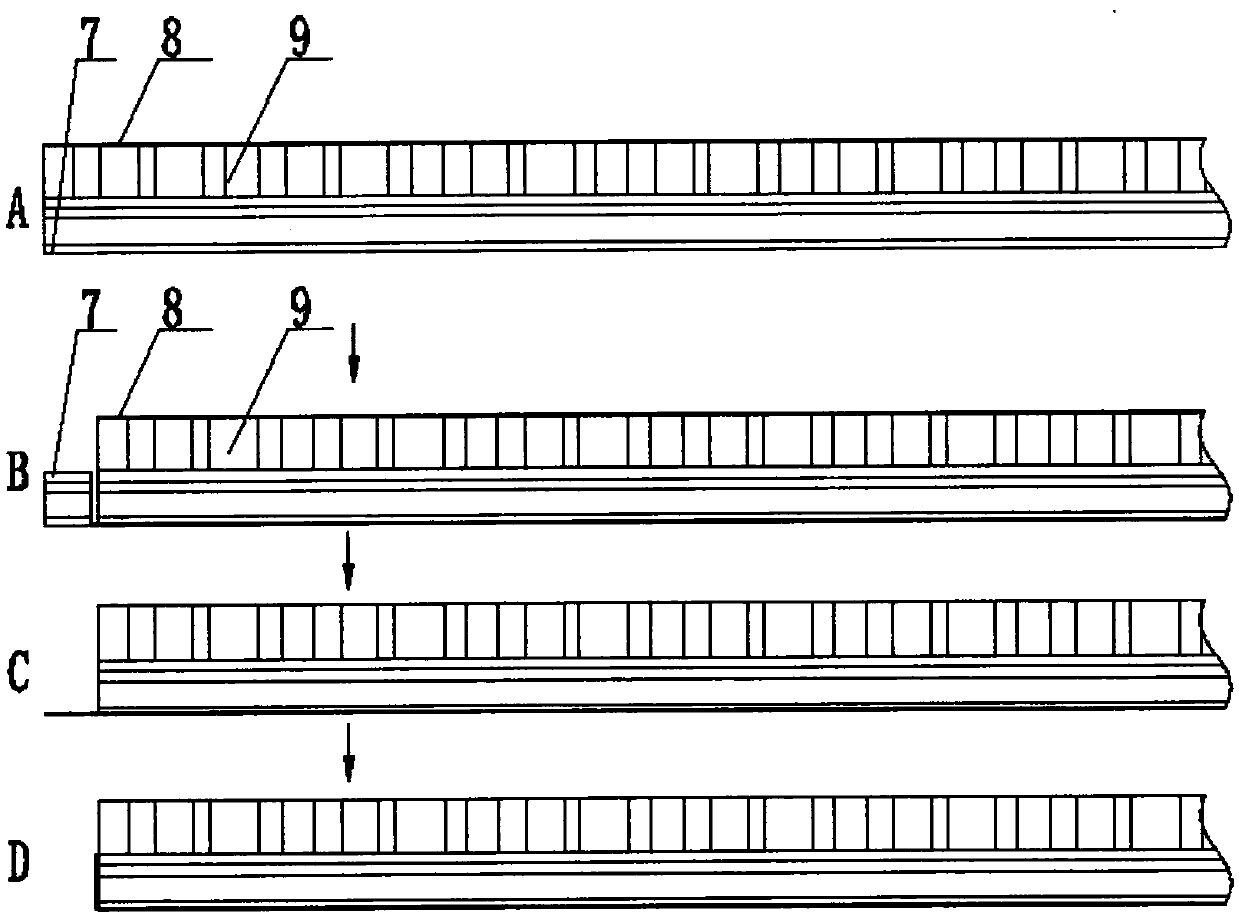

[0041] The process of making thermal insulation sandwich curtain wall panels is the process of obtaining two flat joints by post-processing the cross-section of ordinary sandwich panels. Generally, the production process of thermal insulation sandwich curtain wall panels is divided into three steps: ① cut off the inner steel plate, remove the inner steel plate and core material on the cut surface; ② punch out the special-shaped edges on both sides of the outer steel plate; Form a flush joint. The device of the present invention arranges these three process steps and the corresponding devices continuously on a frame according to the order of ①②③③②①, and ensures the accuracy of the plate size through the encoder counting and hard limit. The present invention splits the processing process for both ends of the plate into three steps corresponding to the three processing stations of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com