Process for gelling solidifying of heavy metals in municipal solid waste incineration fly ash by adding mineral powder

A domestic waste incineration and solidification technology, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of easy leaching of heavy metals, high capacity expansion ratio, unfavorable solidified body resource utilization, etc., to achieve Good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

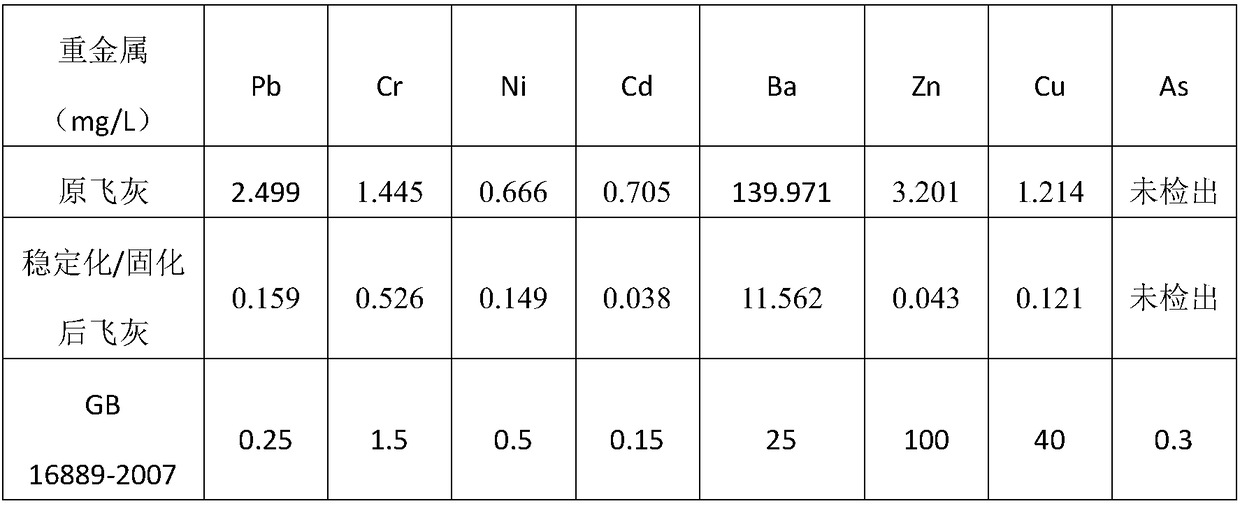

[0027] Take 80 parts of domestic waste incineration fly ash, 4 parts of calcium hydroxide, add 60 parts of water, place in a mixer and stir at a slow speed of 100 rpm for 3 hours, dry at 105 °C, grind through a 100-mesh sieve for later use; weigh 70 Put 30 parts of pretreated waste incineration fly ash and 30 parts of S95 ore powder in a container, place them in a mixer and stir for 2 minutes at a frequency of 50 rpm, mix well, then weigh 3 parts of sodium hydroxide and dissolve in 40 parts of distilled water Make an alkali solution; add the alkali solution to the mixture, place it in a mixer and stir at a frequency of 100 rpm for 5 minutes, and then stir at a frequency of 600 rpm for 5 minutes; take out the mud and beat it for 1 minute to form a muddy mass, and use Wrap and seal with plastic wrap to isolate the air, remove the wrap after curing in a constant temperature curing box at 25°C for 20 hours, and place the cured body in a water curing box at 25°C for 14 days to obtai...

Embodiment 2

[0031] Take 100 parts of domestic waste incineration fly ash, 5 parts of potassium hydroxide, add 70 parts of water, put it in a mixer and stir at a slow speed of 150 rpm for 2.5 hours, dry it at 100°C, and grind it through a 100-mesh sieve for later use; weigh 80 parts of pretreated waste incineration fly ash and 20 parts of S105 ore powder are placed in a container, placed in a mixer and stirred at a frequency of 80 rpm for 3 minutes, mixed evenly, and then weighed and dissolved in 4 parts of calcium hydroxide in 50 parts of distilled water Add alkaline solution to the mixture, place it in a mixer and stir at 150 rpm for 3 minutes, then at 700 rpm for 3 minutes; take out the mud and beat it for 0.5 min to form a muddy mass , wrapped with plastic wrap to seal off the air, cured in a constant temperature curing box at 40°C for 24 hours, then removed the wrapping, and placed the cured body in a water curing box at 20°C for 28 days to obtain a gelled solidified body. The heavy m...

Embodiment 3

[0035] Take 120 parts of domestic waste incineration fly ash, 6 parts of sodium hydroxide, add 80 parts of water, put it in a mixer at 200 rpm and stir for 2 hours at a slow speed, dry it at 95°C, grind it through a 100-mesh sieve for later use; weigh 85 Put 1 part of pretreated waste incineration fly ash and 15 parts of S75 ore powder in a container, place in a mixer and stir for 5 minutes at a frequency of 100 rpm, mix well, then weigh 5 parts of potassium hydroxide and dissolve in 35 parts of distilled water Make an alkali solution; add the alkali solution to the mixture, place it in a mixer and stir at a frequency of 200 rpm for 2 minutes, and then stir at a frequency of 800 rpm for 4 minutes; take out the mud and beat it for 2 minutes to form a muddy mass, and use Wrap it with plastic wrap and seal it to isolate the air. After curing for 30 hours in a constant temperature curing box at 30°C, remove the wrapping, and place the cured body in a water curing box at 30°C for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com