Nitrogen-doped carbon nano composite material coated by hollow copper doped monocrystalline silicon and preparation method

A nanocomposite material, nitrogen-doped carbon technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. Insufficient and other problems, to achieve the effect of rigorous and mature preparation process, excellent catalytic activity, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

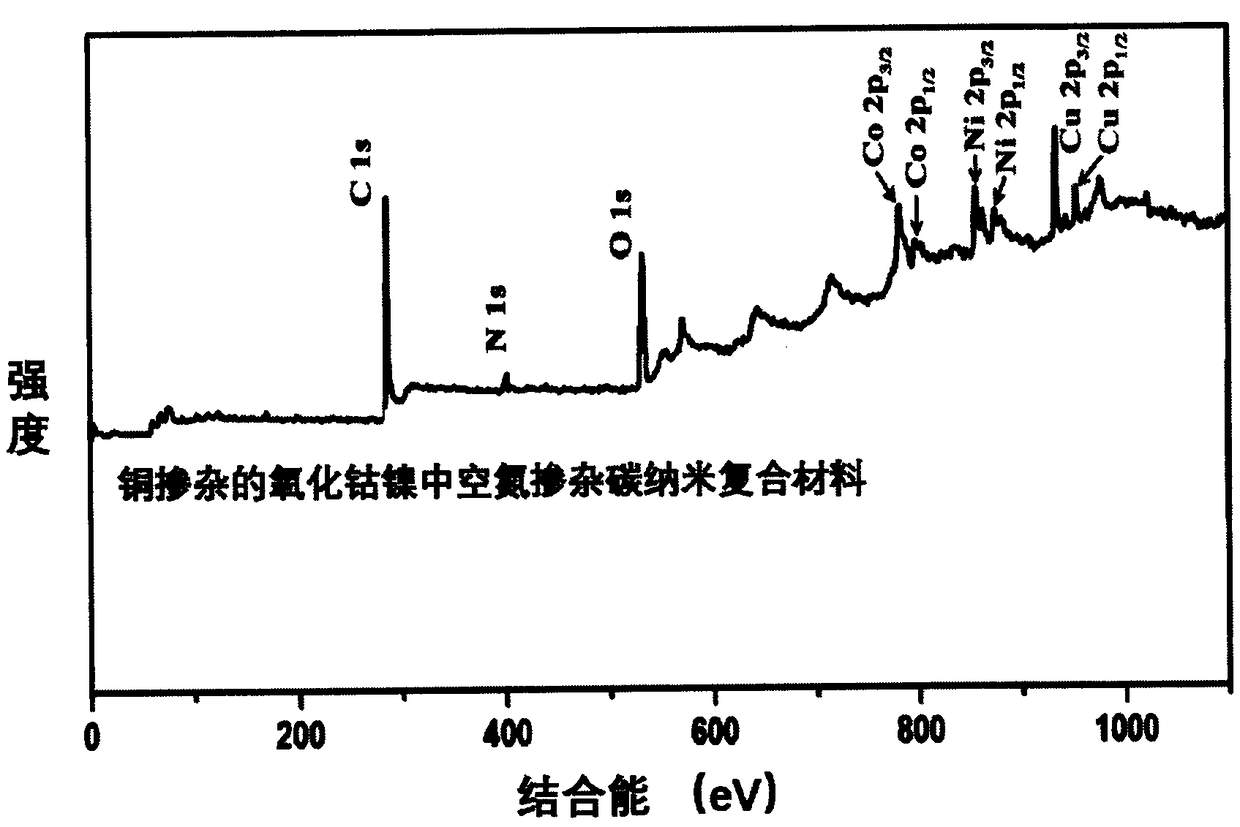

[0043] A hollow copper-doped cobalt-nickel oxide-coated nitrogen-doped carbon nanocomposite material comprises a hollow nitrogen-doped carbon material, and the hollow nitrogen-doped carbon material is coated with copper-doped cobalt-nickel oxide. The hollow nitrogen-doped carbon material has a hollow polyhedral structure.

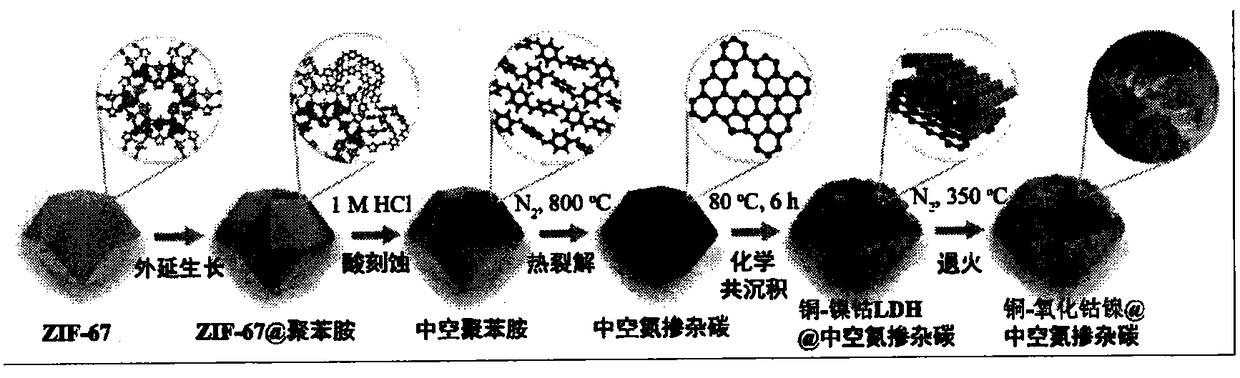

[0044] The preparation method of the nitrogen-doped carbon nanocomposite material coated with hollow copper-doped cobalt-nickel oxide is as follows:

[0045] Step 1: Coat a layer of polyaniline on the surface of ZIF-67 to obtain ZIF-67@polyaniline composite material, and obtain hollow polyaniline by acid etching the obtained ZIF-67@polyaniline composite material:

[0046] Disperse the ZIF-67 powder in 100 mL of water, and disperse uniformly by ultrasonic for 20 min to obtain a dispersion liquid, the concentration of ZIF-67 is 1 mg / mL. Then 20 μL of aniline (Sigma-Aldrich) monomer was added into the above dispersion liquid to make it uniformly dispersed. S...

Embodiment 2

[0060] Similar to the nitrogen-doped carbon nanocomposite material coated with hollow copper-doped cobalt-nickel oxide in Example 1, the difference is that the annealing temperature described in step 5 in Example 1 is changed to 450 ° C, and the obtained product is marked as Hollow copper-doped cobalt-nickel oxide-coated nitrogen-doped carbon nanocomposite-1.

Embodiment 3

[0062] Similar to the nitrogen-doped carbon nanocomposite material coated with hollow copper-doped cobalt-nickel oxide in Example 1, the difference is that the heat treatment temperature in the argon atmosphere described in step 3 in Example 1 is changed to 700 ° C, and the obtained The product is labeled as hollow copper-doped cobalt-nickel oxide-coated nitrogen-doped carbon nanocomposite-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com