Chemical sewage filtering method

A chemical sewage and filtration method technology, applied in the direction of chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of equipment not working normally, sewage pipe blockage, difficult to clean, etc., to improve the filtration performance of the filter element and ensure normal use , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

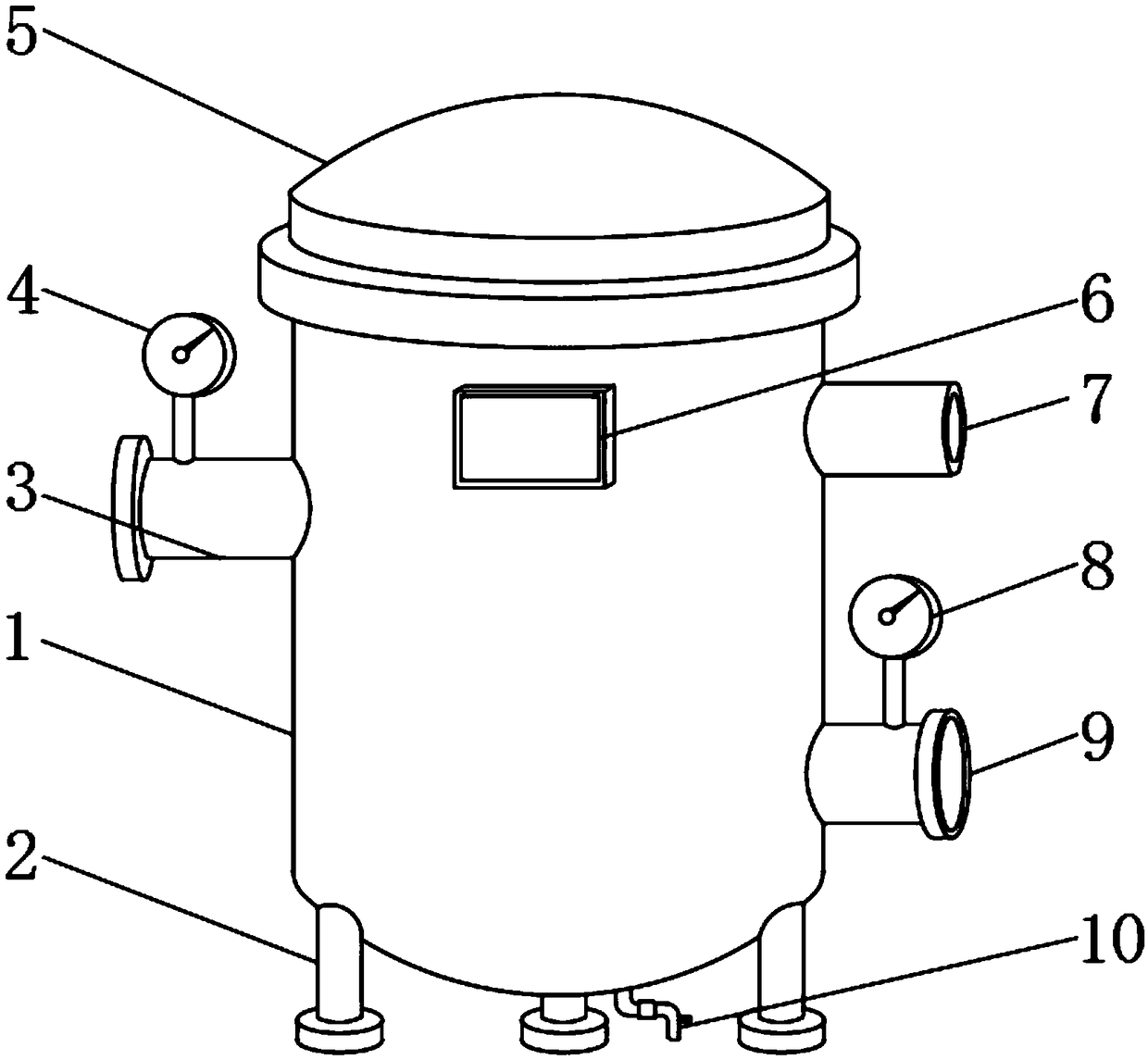

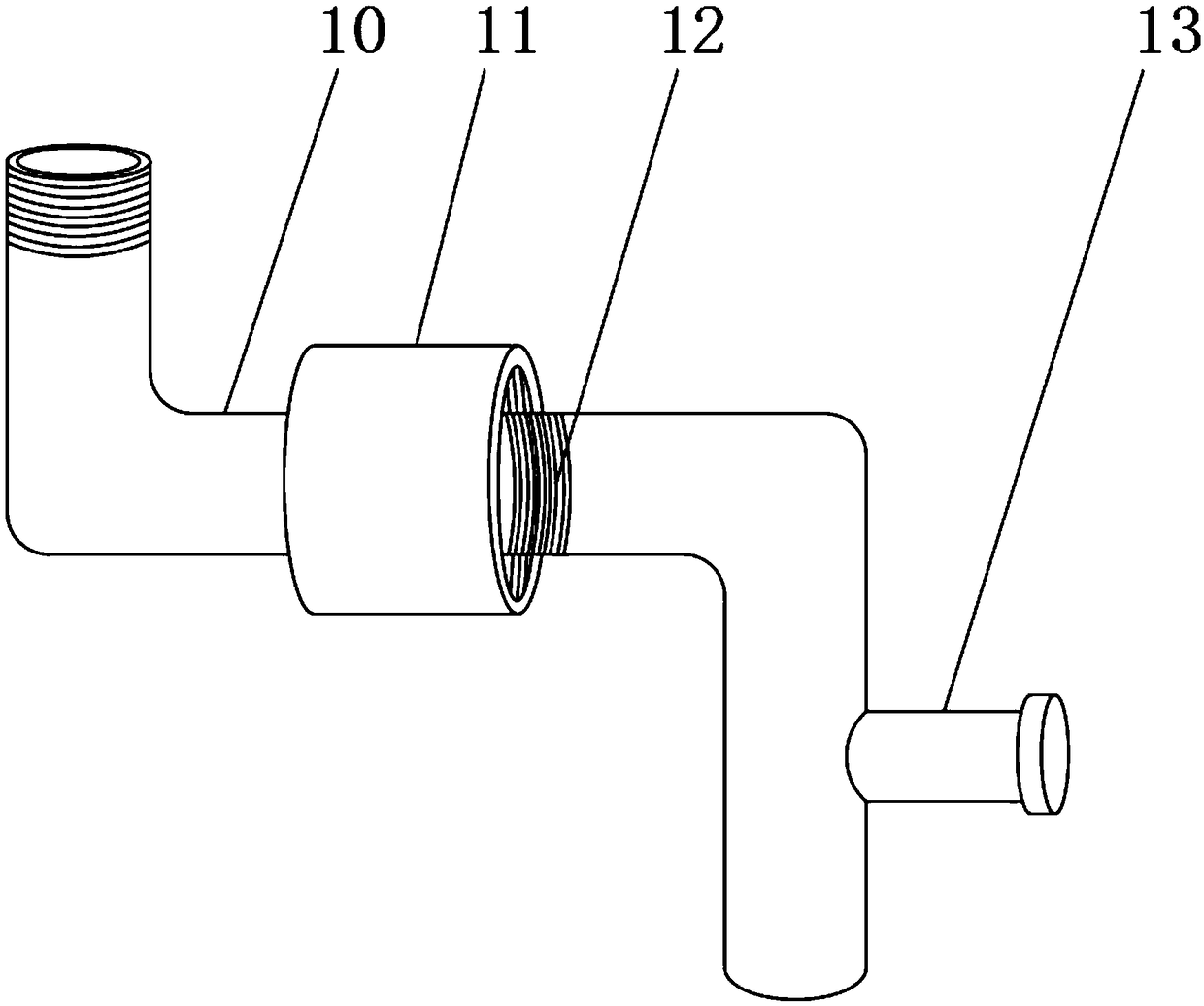

[0022] The first embodiment: see Figure 1-3 As shown, the present invention provides a chemical sewage filtering device, comprising: a support mechanism, the support mechanism includes a sewage filter barrel 1 and a sewage inlet pipe 3, the upper end of the sewage filter barrel 1 is provided with a bucket cover 5, the The lower end of the sewage filter bucket 1 is provided with a detachable sewage pipe 10 and three sets of brackets 2, and a casing 11 is movably installed on the detachable sewage pipe 10, and the position of the detachable sewage pipe 10 close to the casing 11 is provided with a screw thread Circle 12, and a valve 13 is movably installed near the lower end of the detachable sewage pipe 10, and a backwash water pipe 7 is fixedly installed near the upper end of the sewage filter bucket 1, and the sewage filter bucket 1 is located below the backwash water pipe 7 A clean water discharge pipe 9 is arranged at the position of the clean water discharge pipe 9, and a ...

no. 2 approach

[0026]The second embodiment: a chemical sewage filter device, including: a support mechanism, the support mechanism includes a sewage filter barrel 1 and a sewage inlet pipe 3, the upper end of the sewage filter barrel 1 is provided with a barrel cover 5, and the sewage filter The lower end of the barrel 1 is provided with a detachable sewage pipe 10 and three sets of brackets 2, and a sleeve 11 is movably installed on the detachable sewage pipe 10, and a threaded ring 12 is provided at a position close to the sleeve 11 of the detachable sewage pipe 10. , and a valve 13 is movably installed near the lower end of the detachable sewage pipe 10, and a backwash water pipe 7 is fixedly installed near the upper end of the sewage filter bucket 1, and the sewage filter bucket 1 is located below the backwash water pipe 7 A clean water discharge pipe 9 is arranged at the clean water discharge pipe 9, and a No. 2 flow meter 8 is arranged on the clean water discharge pipe 9; the sewage inl...

no. 3 approach

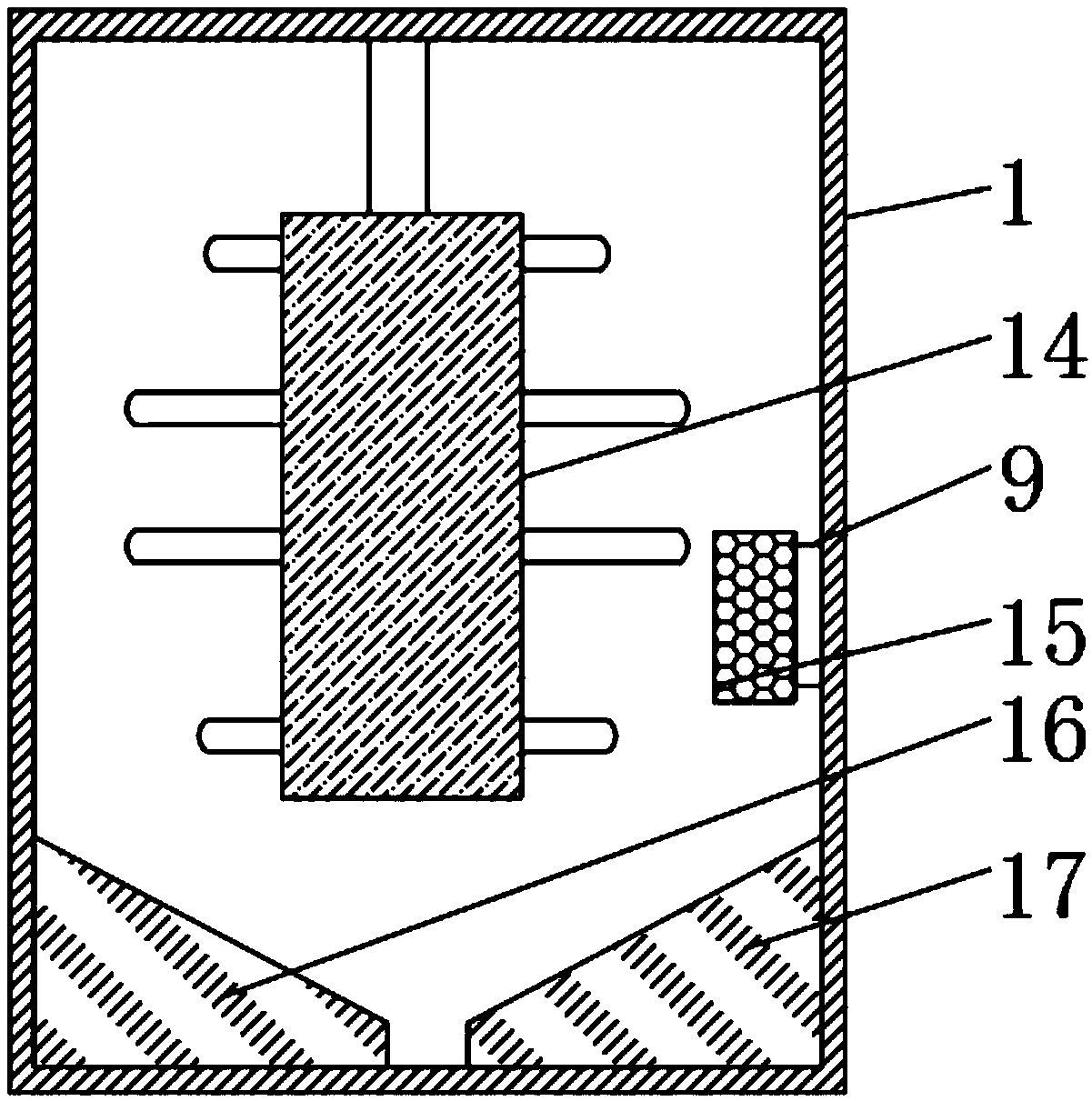

[0035] The third embodiment: a chemical sewage filtration method, in which a rotatable filter element 14 is fixedly suspended in the sewage filter bucket 1, and the water inlet speed and water outlet speed on the sewage filter bucket 1 are monitored and set, so as to control their volume In this process, the filter core 14 is driven by the motor to alternate between two working modes of variable acceleration and smooth rotation, and the length of the variable acceleration rotation cycle is much shorter than the length of the smooth rotation cycle. Sewage filter bucket 1 The bottom of the barrel body adopts two built-in filter cotton and the detachable trapezoidal inner bottom 16, 17 which is set opposite to form a sewage outlet, and at the same time complete the secondary absorption and filtration of sewage;

[0036] Finally, carry out the backwashing of the filter element, turn off the motor, stop the rotation of the filter element 14, stop injecting sewage, and only keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com