Compressing hemostasis band and manufacturing method thereof

A technique of compressing hemostasis and banding, which is applied in the field of tourniquet, can solve the problems of affecting the free movement of patients' two arms, the tourniquet is easy to be contaminated with bacteria, and is inconvenient to promote and popularize, so as to avoid continuous bleeding, facilitate promotion and popularization, and stop bleeding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

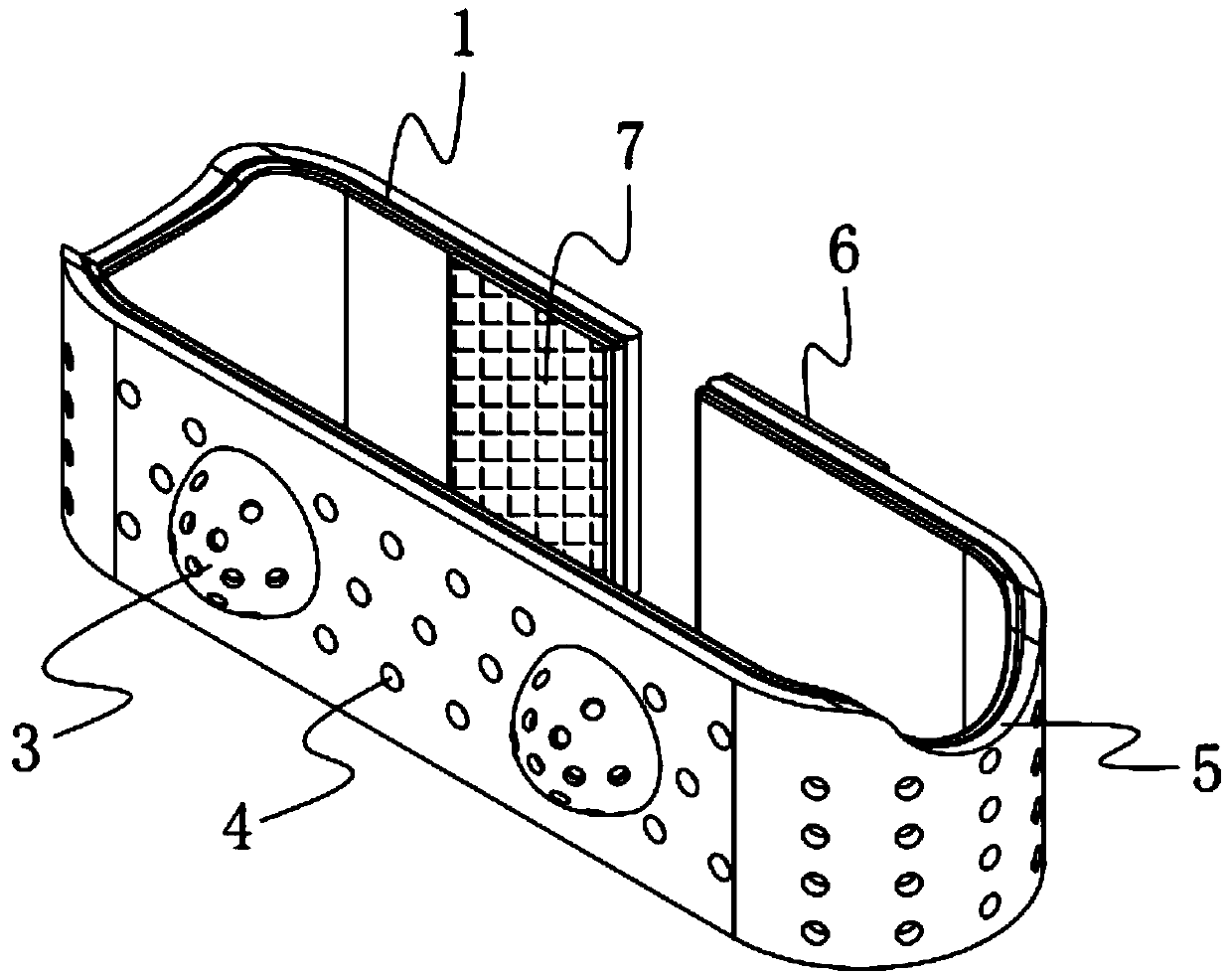

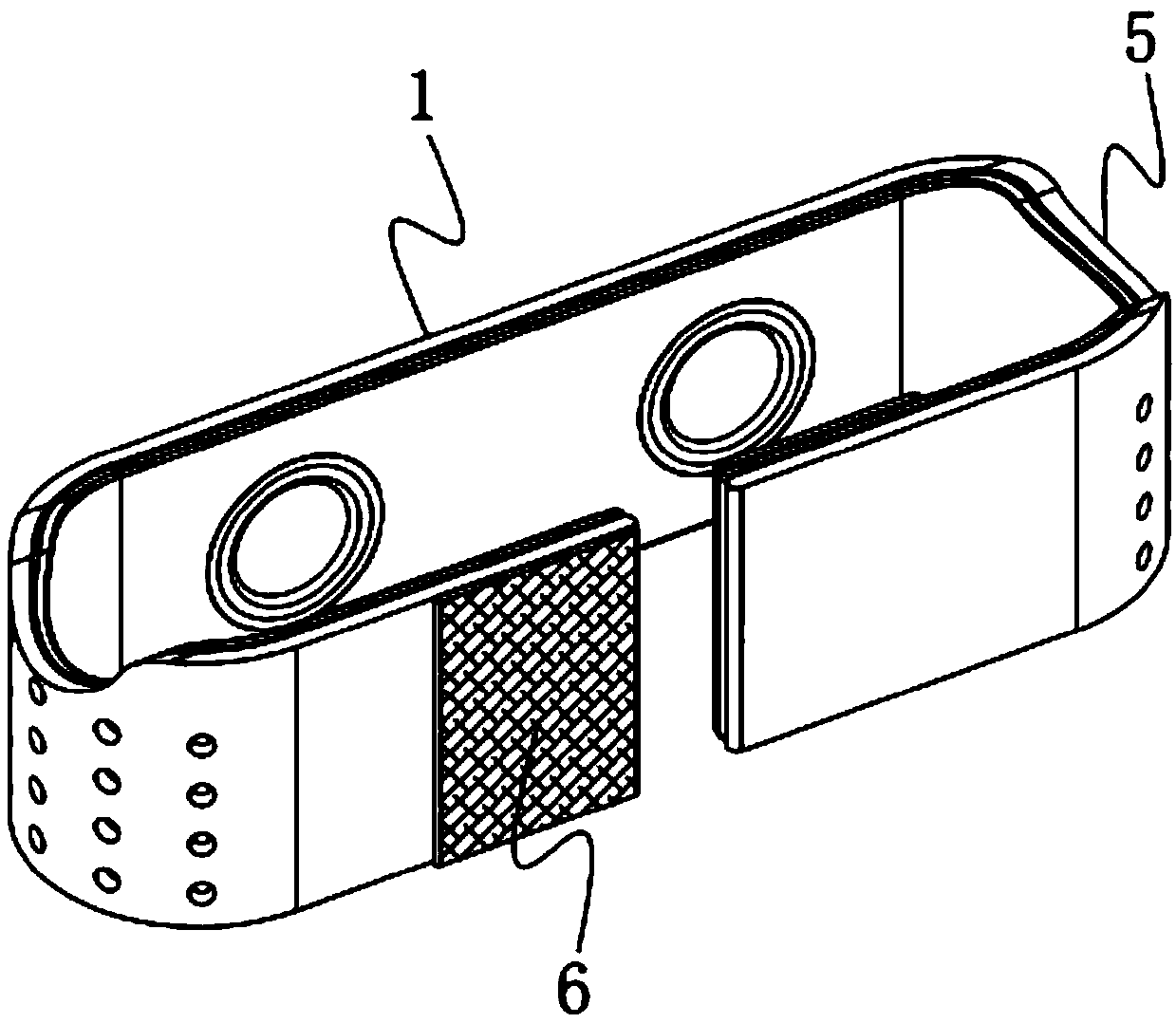

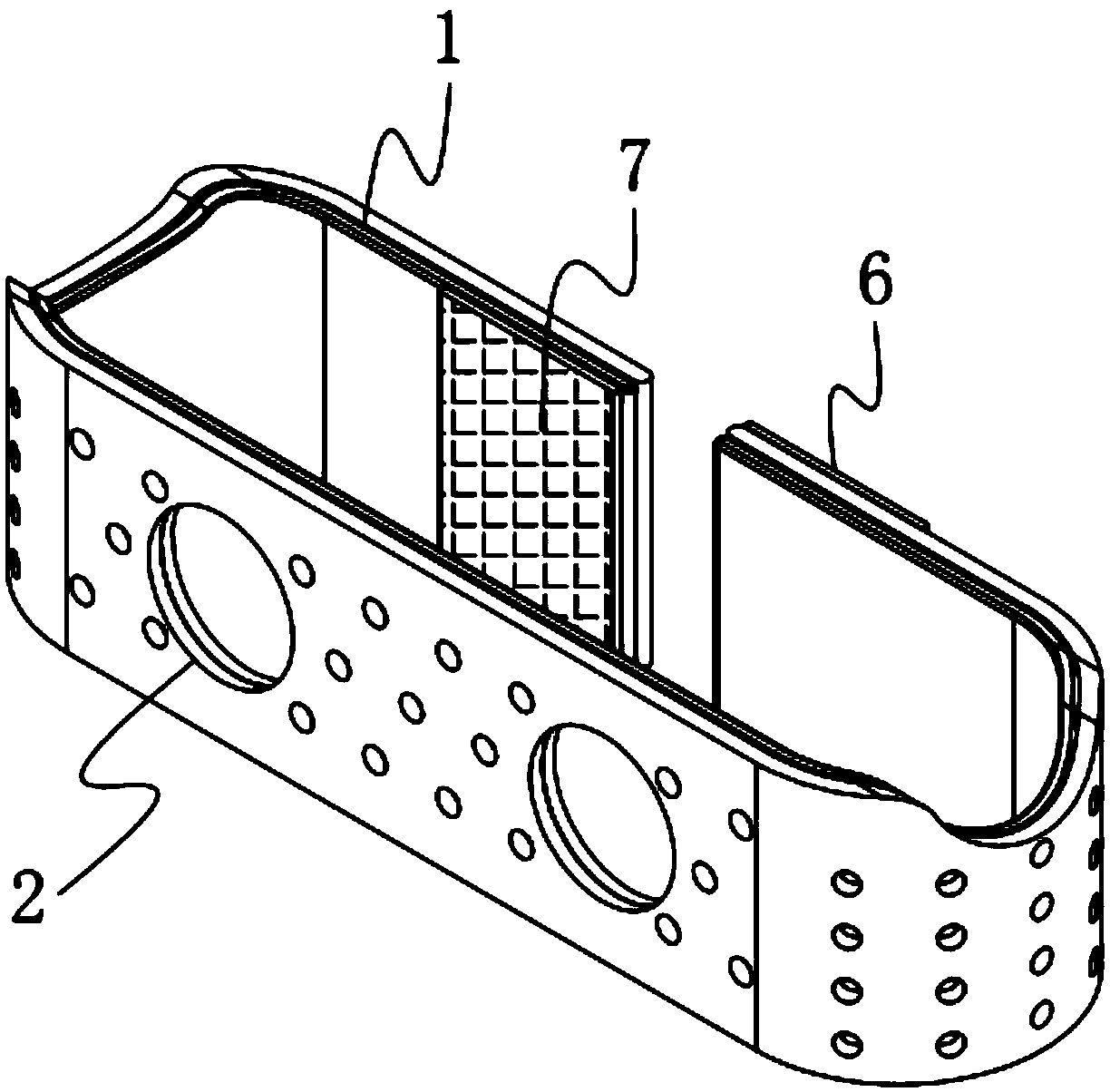

[0062] A compression tourniquet, such as Figure 1-4 As shown, it includes a flat belt body 1, and two installation holes 2 are symmetrically opened in the middle of the flat belt body 1, and a hemostatic unit 3 is fixedly installed inside the two installation holes 2;

[0063] Such as Figure 7-8 As shown, the hemostatic unit 3 includes an arc-shaped silicone cover 10 sewn inside the installation hole 2, a number of first through holes 12 are evenly opened on the arc-shaped silicone cover 10, and the arc-shaped silicone cover 10 The inside of 10 is sticky with curved sponge pad 11.

[0064] The flat belt body 1 is used to be tied to the chest circumference of the patient after a benign breast lump operation, and the hemostatic unit 3 is used to compress the patient's breast to stop bleeding, which can avoid continuous bleeding from the surgical incision of the patient's breast, and is beneficial to the patient's recovery. The first through hole 12 is used for ventilation, w...

Embodiment 2

[0089] The difference from Example 1 lies in the preparation of the arc-shaped silica gel cover 10, and its specific preparation method is as follows:

[0090] Take the following raw materials and weigh them by weight: 35 parts of methyl vinyl phenyl silicone rubber, 14 parts of polyurethane, 10 parts of calcium carbonate powder, 14 parts of melamine resin powder, 10 parts of spices, 2 parts of p-phenylenediamine, diethyl 3 parts of thiourea, 4 parts of paraffin oil, 2 parts of tricresyl phosphate;

[0091] S1. Add the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer and pulverize until the pulverized material has a particle diameter of not more than 8mm, and the speed of the pulverizer is set to 700r / min;

[0092] S2. Add the pulverized material obtained in step S1 into a banbury mixer for banburying. The temperature of the banbury mixer is set at 130° C., the speed is set at 750 r / min, and the banburying time is 25 minutes to obtain banbury mate...

Embodiment 3

[0099] The difference from Example 1 lies in the preparation of the arc-shaped silica gel cover 10, and its specific preparation method is as follows:

[0100] Take the following raw materials and weigh them by weight: 40 parts of methyl vinyl phenyl silicone rubber, 16 parts of polyurethane, 12 parts of calcium carbonate powder, 15 parts of melamine resin powder, 12 parts of spices, 3 parts of p-phenylenediamine, diethyl 4 parts of thiourea, 5 parts of paraffin oil, 3 parts of tricresyl phosphate;

[0101] S1. Add the weighed methyl vinyl phenyl silicone rubber and polyurethane into a pulverizer and pulverize it until the pulverized material has a particle diameter of not more than 8mm, and the speed of the pulverizer is set to 800r / min;

[0102] S2. Put the pulverized material prepared in step S1 into a banbury mixer for banburying. The temperature of the banbury mixer is set to 140° C., the speed is set to 800 r / min, and the banburying time is 30 minutes to obtain banbury m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com