Deep-cooling air separation system of newly-added nitrogen producing tower

A technology of cryogenic air separation and nitrogen generating tower, which is applied in the direction of cold treatment separation, refrigeration and liquefaction, liquefaction, etc., which can solve the problems of poor energy consumption and achieve the effect of reducing configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

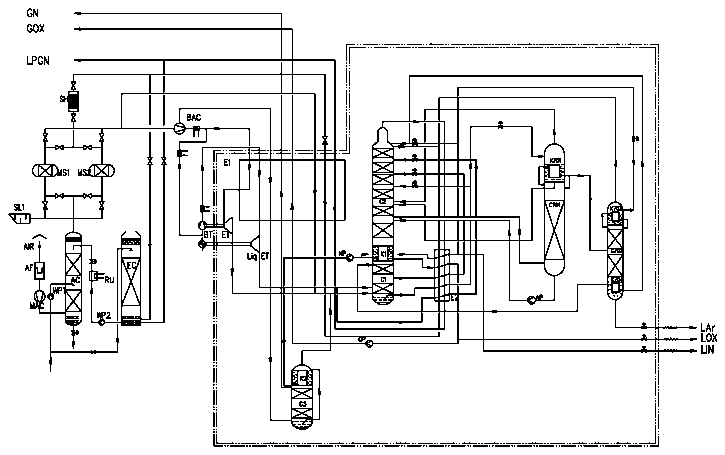

[0029] Example: figure 1 As shown, the present invention is a technological process of purifying air with molecular sieves, pressurizing air, compressing in an oxygen pump, cooling with a booster turbo expander, adopting a structured packing tower and fully rectifying hydrogen-free argon production.

[0030] Raw material air is inhaled from the suction port, dust and other mechanical impurities are removed through the self-cleaning air filter AF, the filtered air enters the centrifugal air compressor MAC, and after being compressed by the compressor, it enters the air cooling tower AC to be cooled; the upper part of the air cooling tower The chilled water enters, the middle part enters the circulating water at normal temperature, and the air passes through the air cooling tower AC from bottom to top, and is cleaned while being cooled.

[0031] After the circulating water enters the water-cooling tower, it is sent into the dirty nitrogen gas. Using the characteristic that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com