A multi-purpose continuous positive pressure filter equipment

A filtration equipment and multi-purpose technology, applied in filtration separation, membrane filter, mobile filter element filter, etc., can solve the problems of difficult to replace and clean filter cloth, high residual moisture in filter cake, difficult to hold gas, etc., to achieve clean replacement Simple, small footprint, compact model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

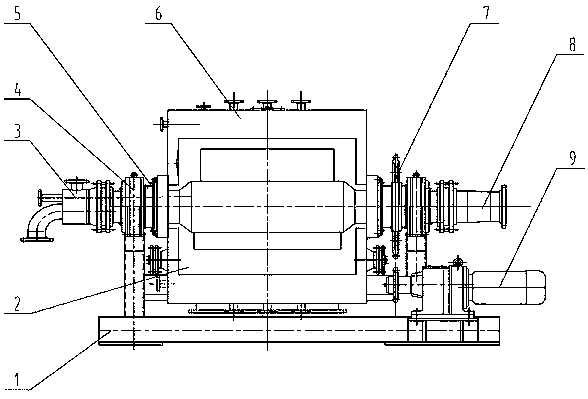

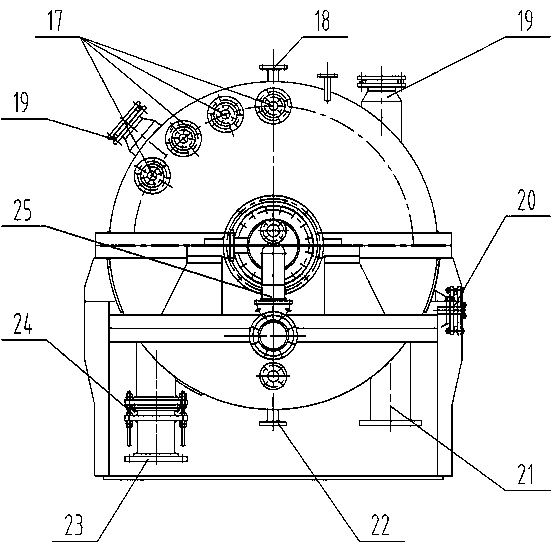

[0018] Such as Figure 1~3 As shown, a multi-purpose continuous positive pressure filtration equipment includes a frame 1, a lower half casing assembly 2 and a transmission system 9 arranged on the frame 1.

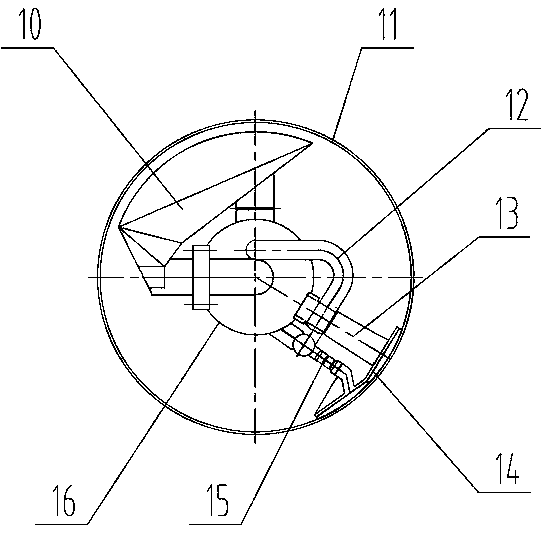

[0019] The top of the lower half casing assembly 2 is connected with the upper half casing assembly 6, and the upper half casing assembly 6 is connected with the lower half casing assembly 2 to form a shell; the inside of the casing is provided with a hollow runner assembly 3. Drum assembly 11; the housing is connected with the hollow runner assembly 3 through the sealing assembly 5, and the housing is connected with the frame 1 through the support assembly 4 at both ends to form an integral device; the transmission shaft in the transmission system 9 is provided with There are large and small sprockets 7, and the transmission system 9 is connected with the hollow runner assembly 3 through the large and small sprockets 7.

[0020] Wherein: the lower half of the casing ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com