Air energy drying device for sludge

An air energy, air energy heat pump technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve high room temperature, insufficient sludge reduction, heat loss, etc. problem, to achieve the effect of high calorific value of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Take an urban sewage treatment plant as an example (a sewage volume of 10,000 tons / day), the moisture content of the sludge at the outlet of the centrifugal dehydrator is about 80% (sludge output is about 6t / d), and the sludge is sent to In the sludge buffer silo, the sludge silo has a volume of 12m 3 , Maintain 2d effective volume. The silo is equipped with a shaftless screw to prevent the sludge from being bridged in the silo, and is transported to the air energy drying equipment through the sludge pump.

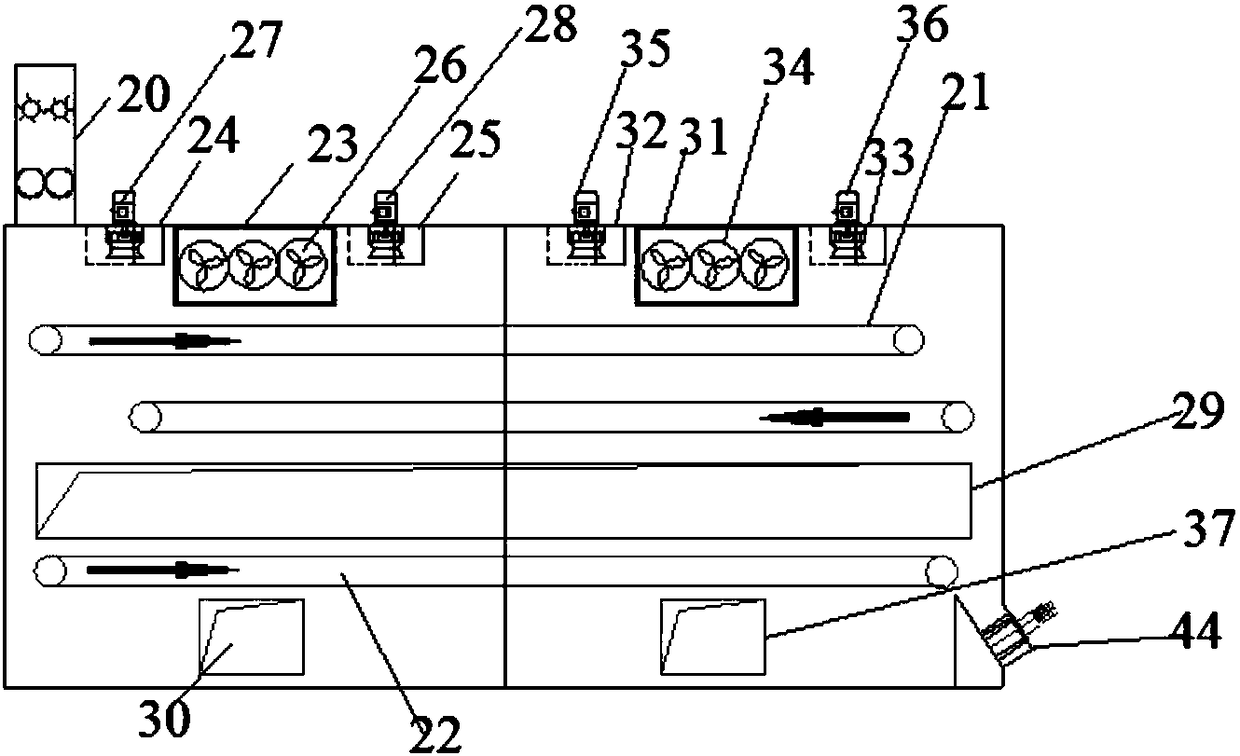

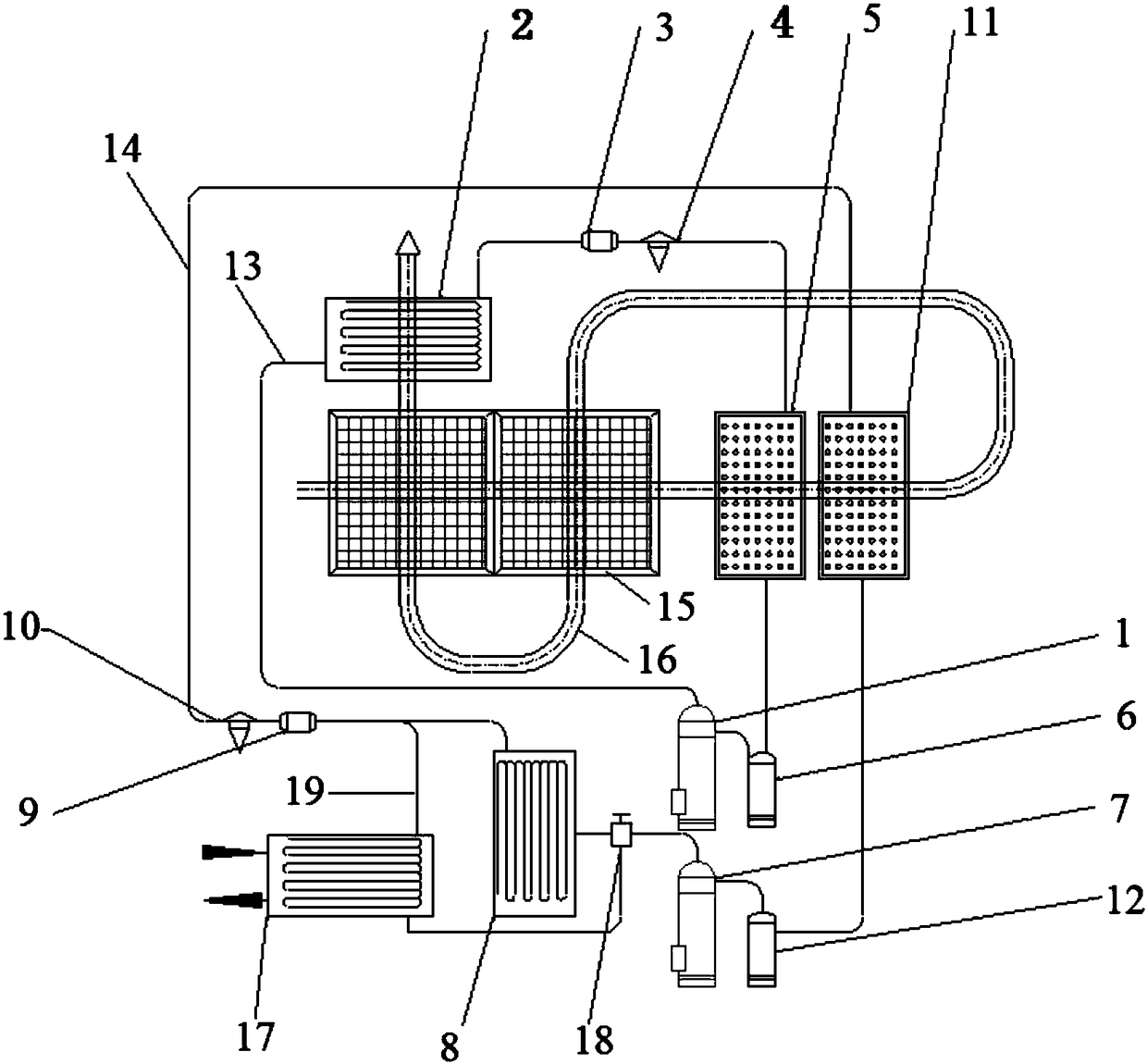

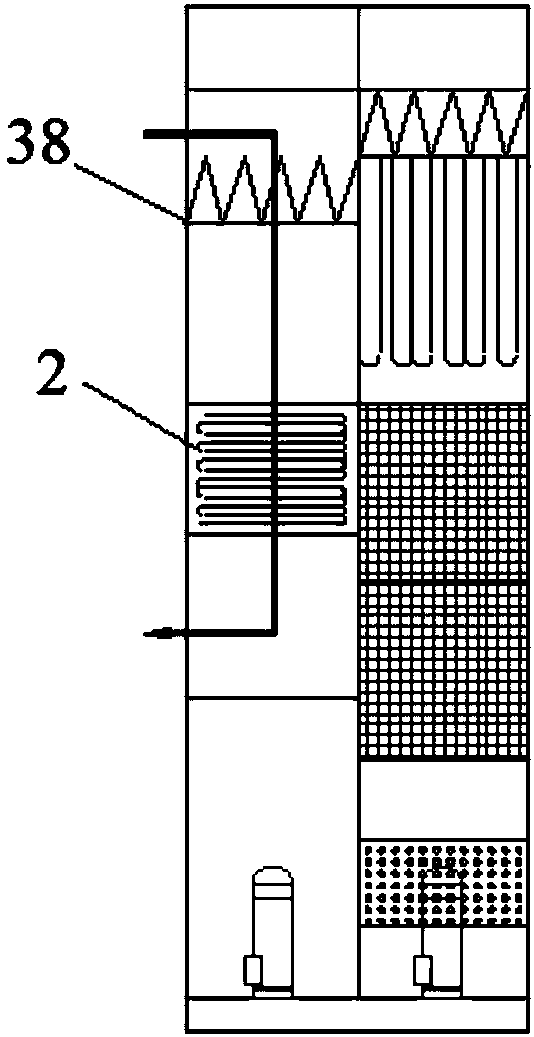

[0046] The air energy drying equipment is a continuous operation mode, mainly including the mesh belt machine part and the heat pump unit system. A sludge cutting and forming machine is installed on the top of the mesh belt machine. The cutting and forming machine is in the form of a two-axis pair of rollers. The sludge is cut to 6-8mm. An arch breaking device and a level gauge are arranged on the upper part of the cutting machine. The meter is connected to the PCL sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com