Bag tea packaging machine system with countable curve cutting device

A technology of counting curves and teabags, which is applied in packaging and other directions, can solve the problems of not being able to achieve counting and cutting according to the settings, and achieve considerable economic benefits, high recognition, and labor cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

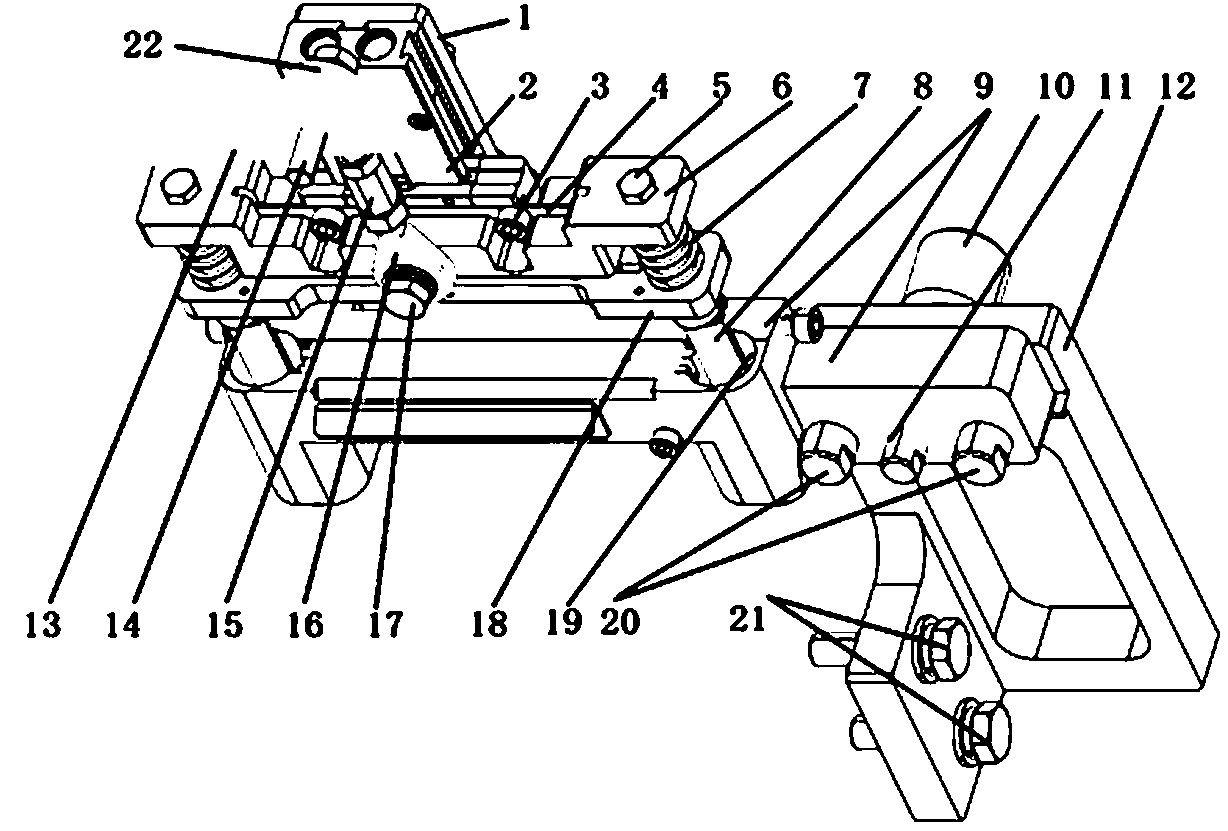

[0027] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

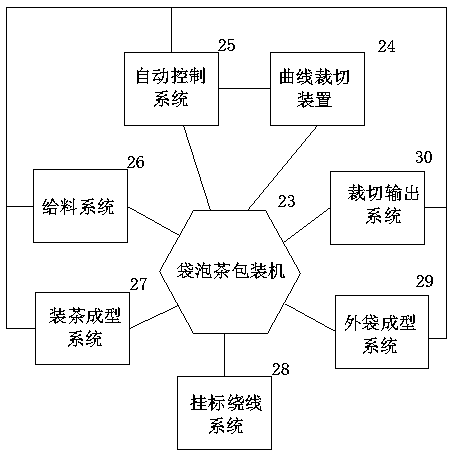

[0028] A tea bag packaging machine system with a countable curve cutting device, comprising a tea bag packaging machine 23, the tea bag packaging machine 23 comprising a curve cutting device 24, an automatic control system 25, a feeding system 26, Tea filling forming system 27, label winding system 28, outer bag forming system 29, cutting output system 30, curve cutting device 24, feeding system 26, tea forming system 27, label winding system 28, outer The bag forming system 29 and the cutting output system 30 are all connected with the automatic control system 25. Further, modules such as various devices and systems of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com