Preparation method of low secondary electron yield non-evaporable getter film

A getter thin film and secondary electron technology, which is applied in ion implantation plating, vacuum evaporation plating, metal material coating process, etc., can solve the problem of high output of secondary electrons and reduction of non-evaporable getter thin film Secondary electron production and other issues, to achieve the effect of reducing secondary electron production, convenient operation, and improving air suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

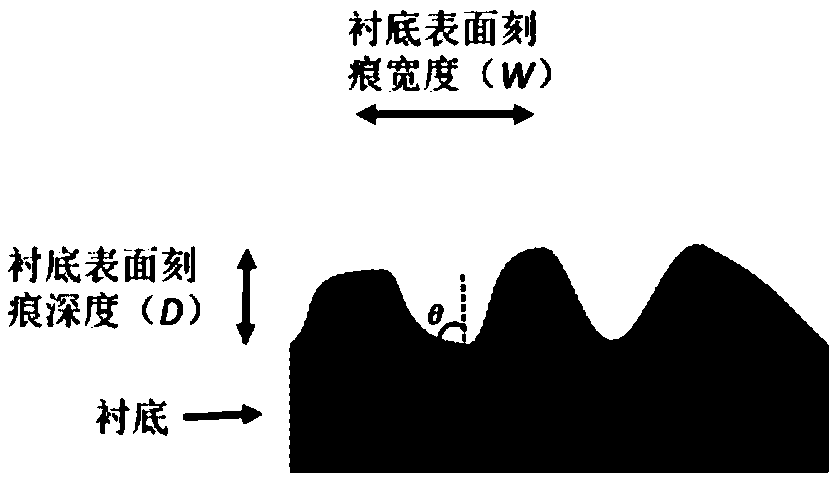

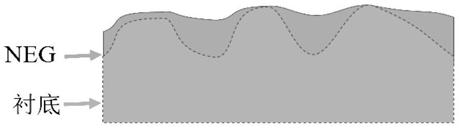

[0017] refer to figure 1 and figure 2 , the preparation method of the low secondary electron yield non-evaporative getter thin film of the present invention comprises the following steps: carrying out laser etching on the substrate surface, making the substrate surface a zigzag groove structure, and then The non-evaporable getter film is sputtered on the surface to obtain a non-evaporable getter film with low secondary electron yield, wherein the notch width W on the substrate surface is 1-200 μm, and the notch depth D on the substrate surface is 1-190 μm, the half-angle width of the notch on the substrate surface is 10°-80°, and the surface area of the substrate after laser etching is 1.1-5 times that of the substrate before laser etching.

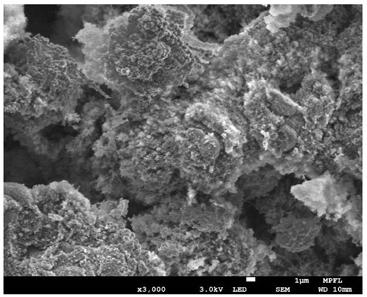

[0018] A non-evaporable getter film is sputtered on the surface of the substrate by using a sputter coating device. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com