Water-based epoxy curing agent and preparation method thereof

A water-based epoxy and curing agent technology, applied in the field of water-based epoxy curing agent and preparation, can solve the problems of easy damage, poor impact resistance, etc., to improve mechanical properties, improve impact resistance and flexibility, and improve leveling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

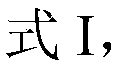

[0027] Preparation of 2,4-TDI modified with MPEG

[0028] The specific formula is as follows:

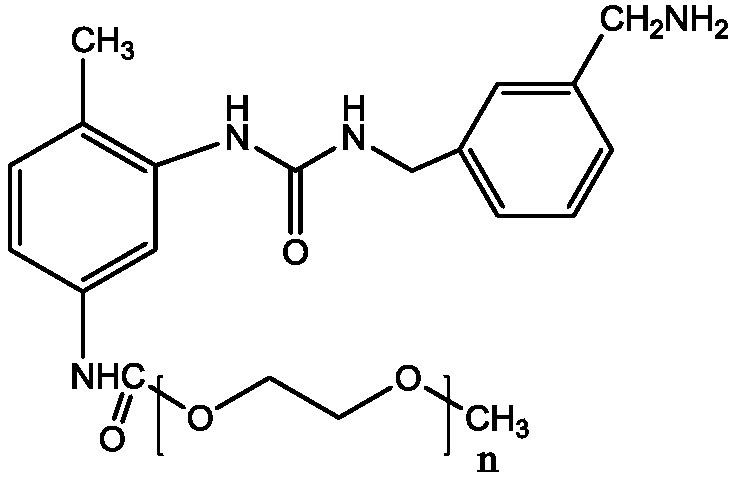

[0029]

[0030]

[0031] Mix the dehydrated MPEG-1000 with methyl isobutyl ketone in advance, add 2,4-TDI (2,4-toluene diisocyanate ) into the four-necked bottle, drop the mixed solution into the four-necked bottle, control the reaction temperature at 40-48°C, and complete the dropwise addition in about 2 hours. After the dropwise addition, raise the temperature to 50-55°C and keep it warm for 2 hours, then test the NCO content , the NCO content is 3.6%, the index is qualified, and it will be used after being filled with nitrogen for protection. The reaction equation is shown in formula II, wherein the average value of n is in the range of 10-35.

Embodiment 2

[0033] Preparation of curing agent containing compound of formula I

[0034] The specific formula is as follows:

[0035] Substance name

[0036] In a four-necked flask equipped with a thermometer, a stirring paddle, and a condenser tube, m-xylylenediamine was added to the four-necked flask and the temperature was raised to 20-35°C, and the resin of Example 1 was added dropwise to the four-necked flask to control the temperature 20-35°C, about 2 hours to complete the dropwise addition. After the dropwise addition, raise the temperature to 60-65°C and keep it warm for 2 hours, remove methyl isobutyl ketone under reduced pressure, add a mixture of deionized and propylene glycol butyl ether to dilute and adjust the viscosity under high-speed dispersion. The desired product was obtained at 80% solids. Its reaction is shown in formula III.

Embodiment 3

[0038] Preparation and Application of Ordinary Waterborne Epoxy Primer

[0039] The specific characteristics of the emulsion formula are as follows:

[0040] Substance name

Parts by mass (g)

WP-6520 Waterborne Epoxy Resin

128

R-900 titanium dioxide

62

ASP-200 Kaolin

20

ZPA antirust pigment

20

MA-7 carbon black

2

3168 defoamer

0.15

TEGO-755W additive

5

Propylene glycol butyl ether

7

Embodiment 2 curing agent

18

K-54

1

[0041] According to the formula shown in the table, the water-based epoxy primer is prepared by staged high-speed stirring. The WP-6520 water-based epoxy resin in the table is the self-made water-based epoxy resin of HLS Company. R-900 titanium dioxide is a commercially available product from DuPont, MA-7 is a commercially available carbon black from Mitsubishi, ASP-200 kaolin is a commercially available product from BASF, ZPA is a comme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com