Ceramic product with graphene oxide anti-corrosive layer and preparation method of ceramic product

A technology for ceramic products and anti-corrosion layers, which is applied in the field of ceramic products containing graphene oxide anti-corrosion layers and its preparation, which can solve the problems of poor plasticity and achieve the effects of large anti-bending coefficient, good anti-corrosion effect, and improved drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

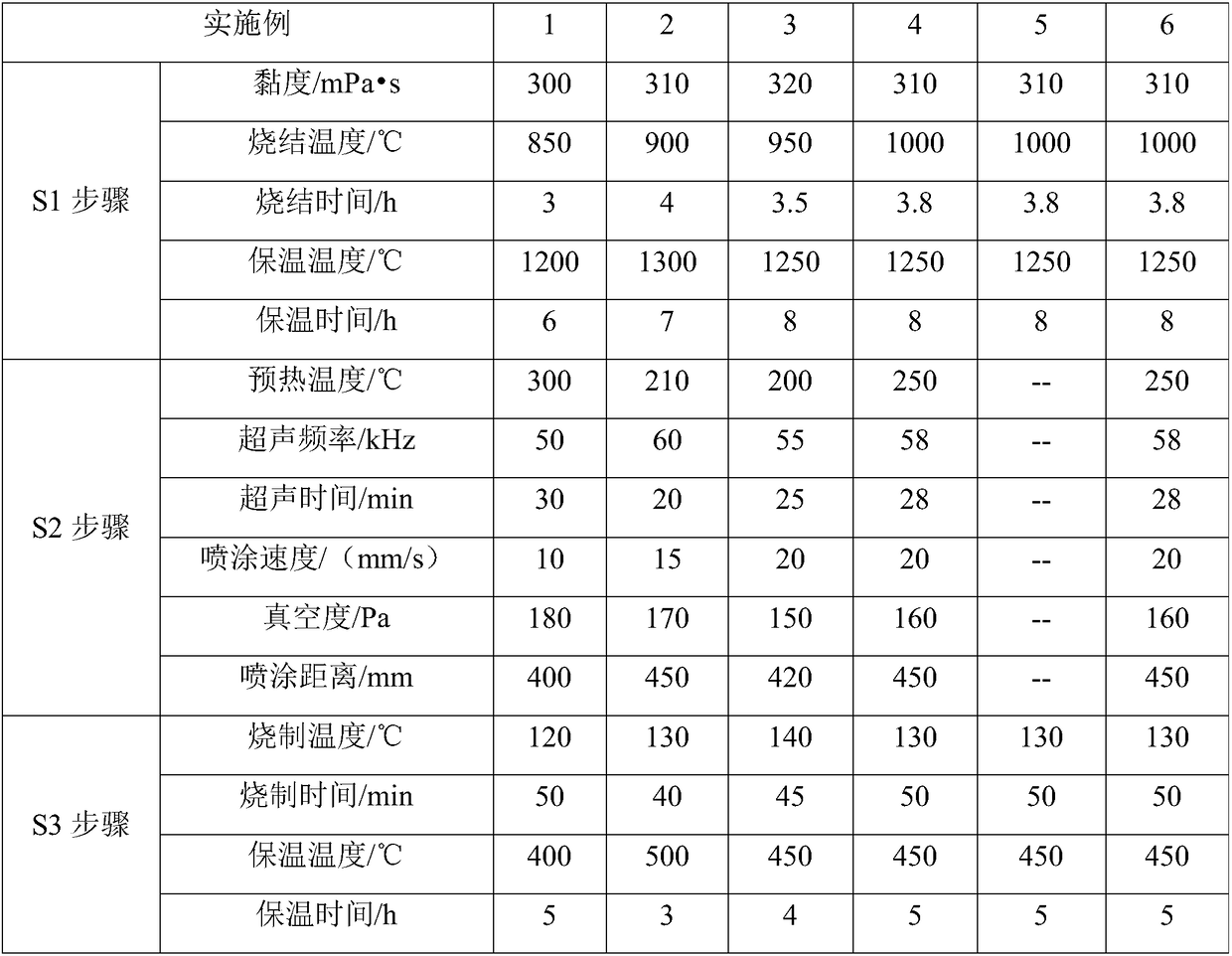

[0034] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0035] A ceramic product containing a graphene oxide anticorrosion layer, comprising a rough body, a graphene oxide anticorrosion layer and a glaze layer:

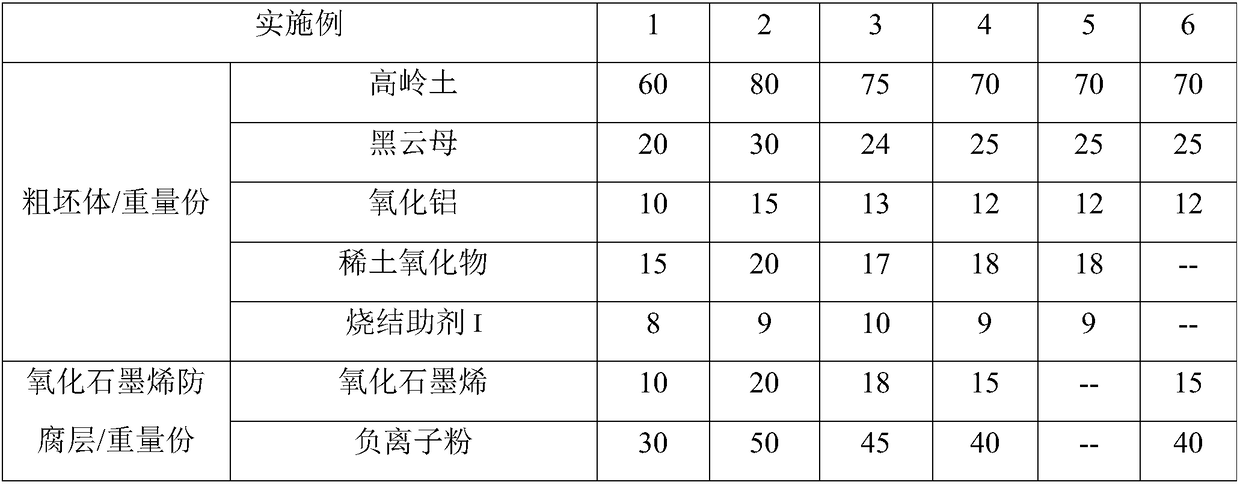

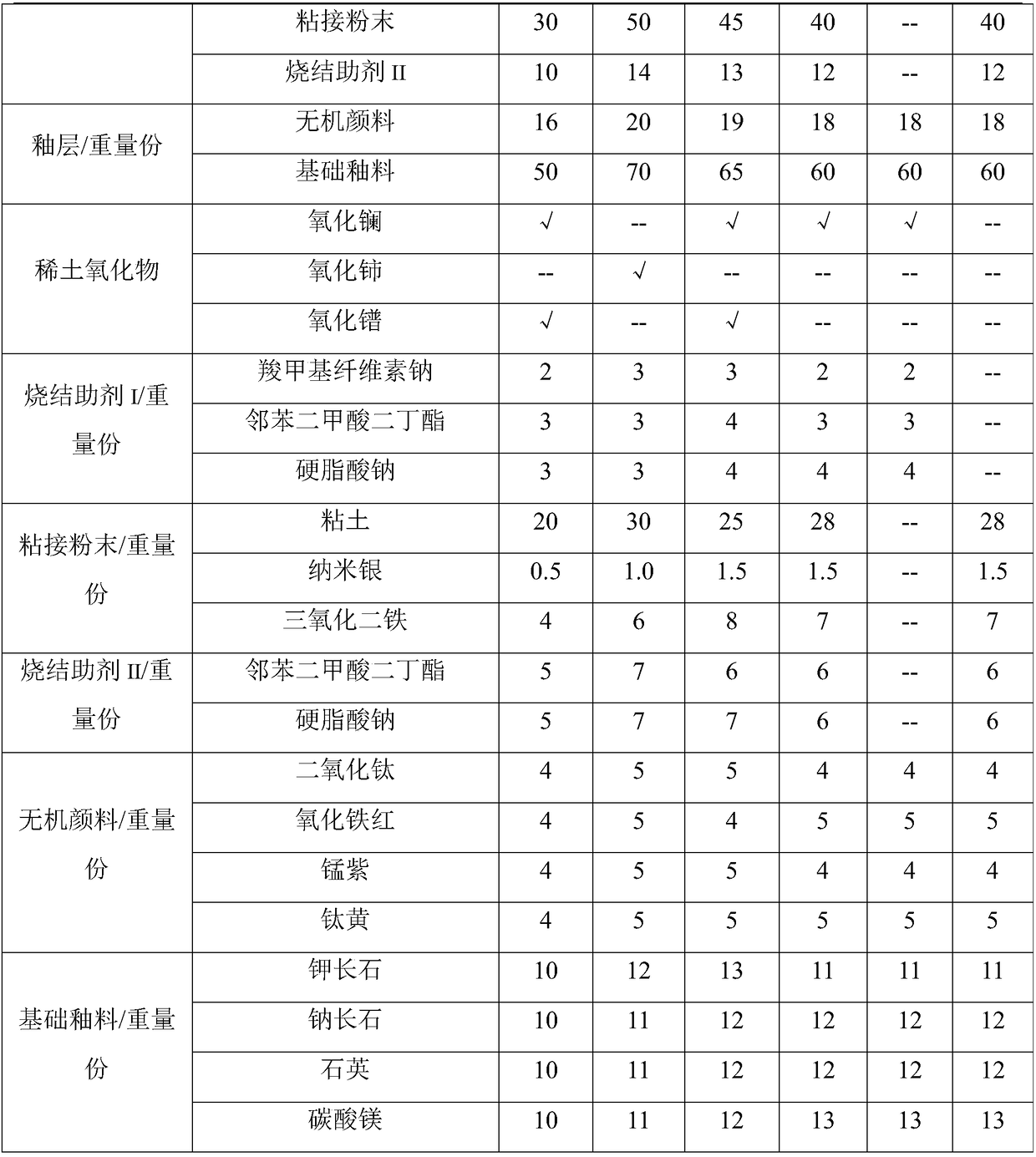

[0036] The rough green body includes the following components by weight: 60-80 parts of kaolin, 20-30 parts of biotite, 10-15 parts of alumina, 15-20 parts of rare earth oxide, and 8-10 parts of sintering aid I;

[0037] The graphene oxide anticorrosion layer includes the following components by weight: 10-20 parts of graphene oxide, 30-50 parts of negative ion powder, 30-50 parts of bonding powder, and 10-14 parts of sintering aid II;

[0038] The glaze layer includes the following components in parts by weight: 16-20 parts of inorganic pigments and 50-70 parts of basic glaze.

[0039] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com