A Visual Measuring Device for Dynamic Contour Error of CNC Machine Tool

A technology of dynamic profile and visual measurement, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of cumbersome measurement work and the inability to apply dynamic profile errors of machine tools, etc., and achieve low cost, high measurement efficiency, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

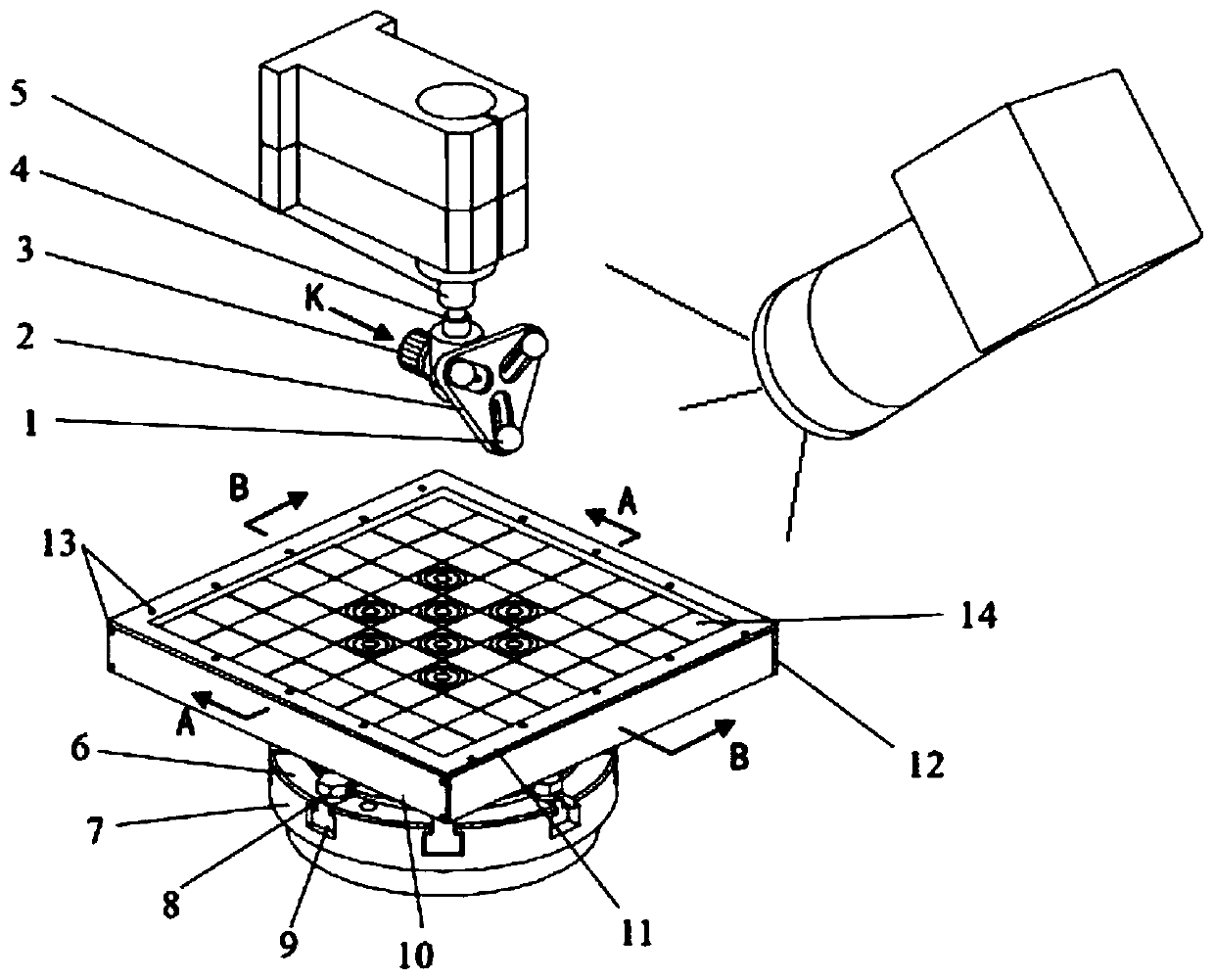

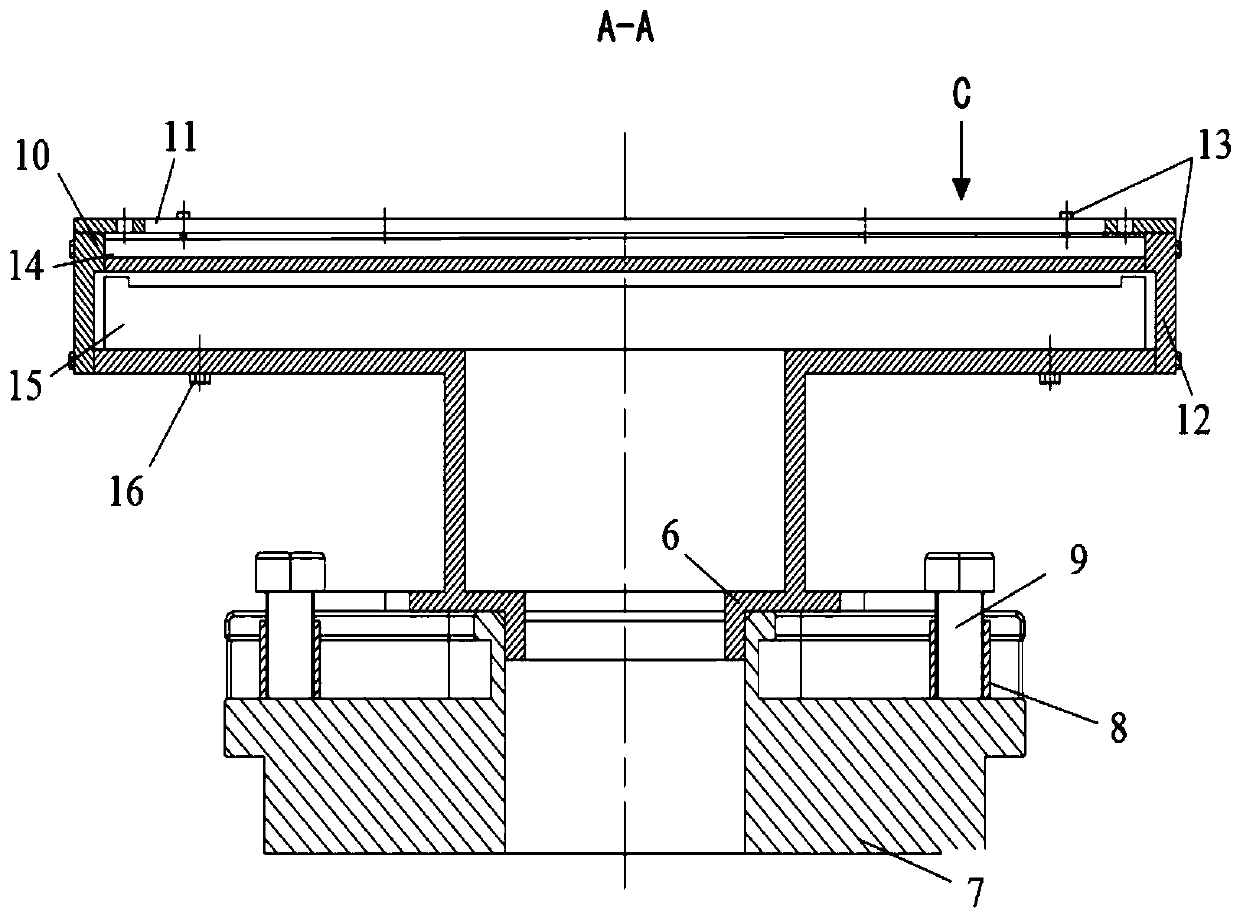

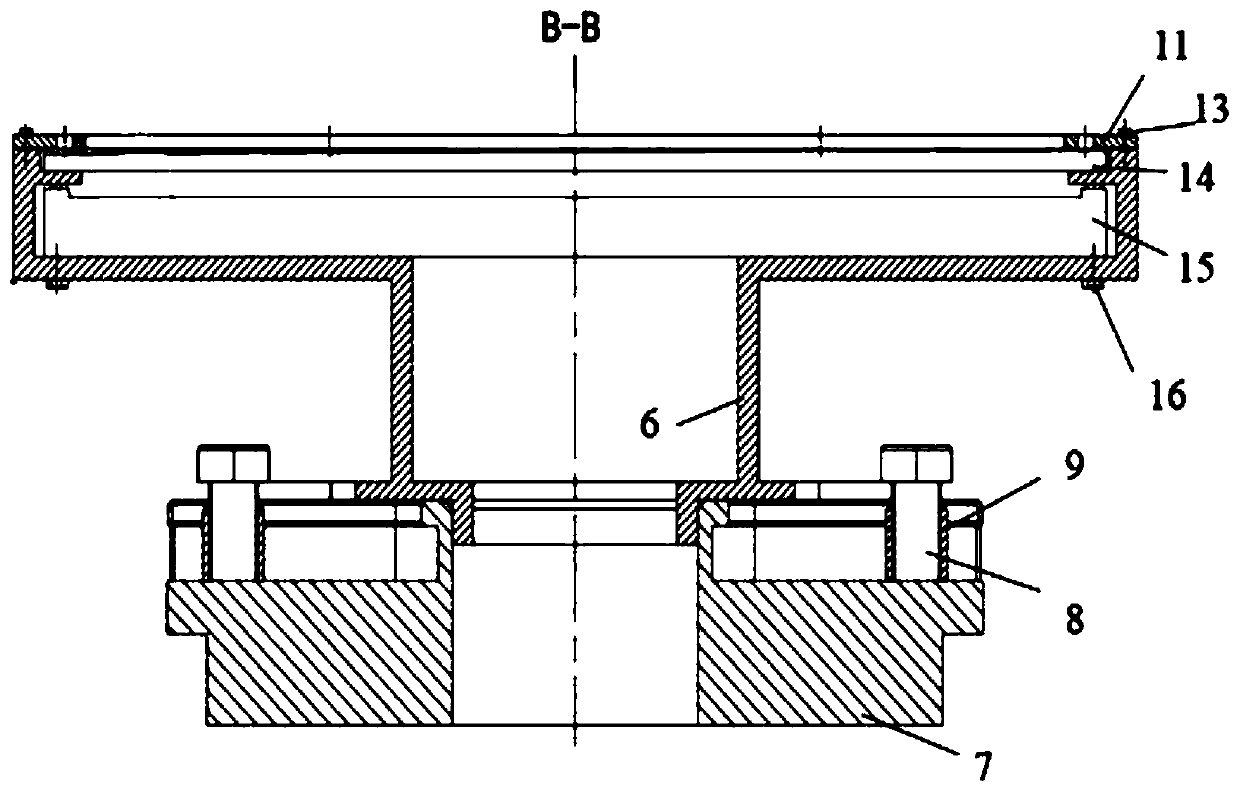

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0013] The structure of the visual measurement device for dynamic contour error of CNC machine tools is shown in the attached figure 1 , 2 , 3, and 4, the device consists of a flexible target and an integrated measurement tooling. Among them, the light source is the constant bright backlight of wordop company, the model is FQG2-260×260, the positioning reference is a photolithographic glass plate of 260mm×260mm×5mm, and the monocular camera is a high frame rate and large resolution industrial camera model EoSens25CXP.

[0014] The flexible target includes a ball head platform 3 , a target base 2 with an equilateral triangle structure, a target ball 1 installed on the target base, target ball fixing bolts 17 and studs 4 . In this embodiment, three target balls 1 are used, and the number of target balls can be appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com