Intermediate frequency inverter automatic welding machine special for smoke exhauster hood

An automatic welding and inverter hood technology, applied in welding power sources, welding power sources, welding equipment, etc., can solve the problems of unstable welding effect, large differences in welding physical properties or thickness ratios, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

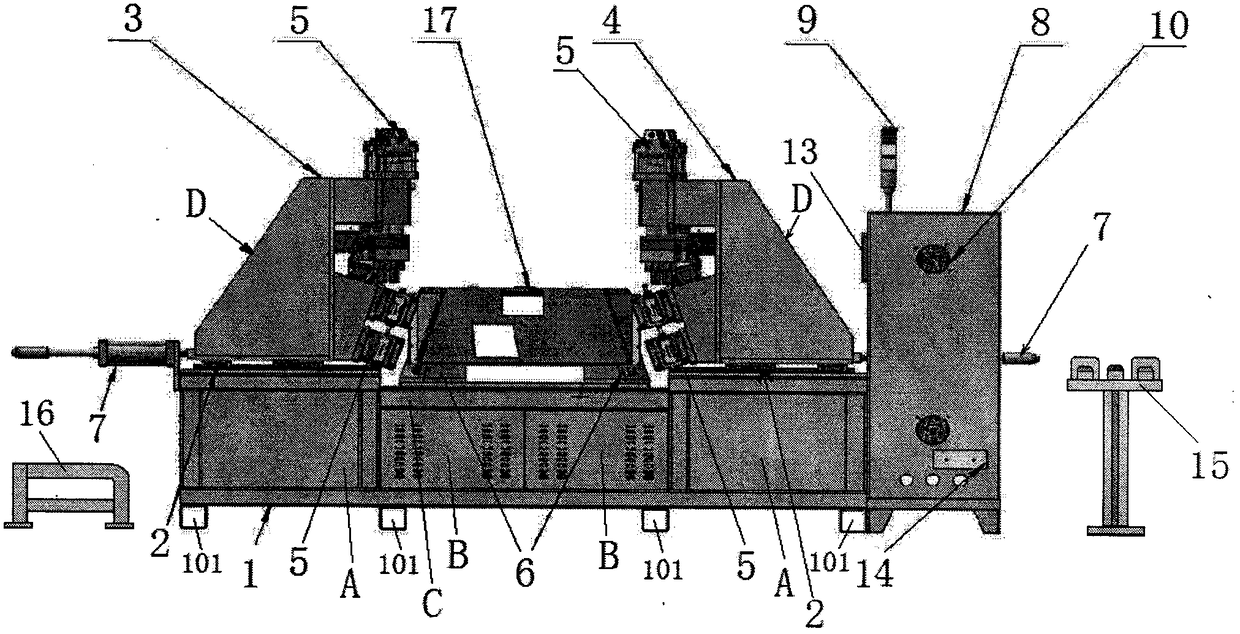

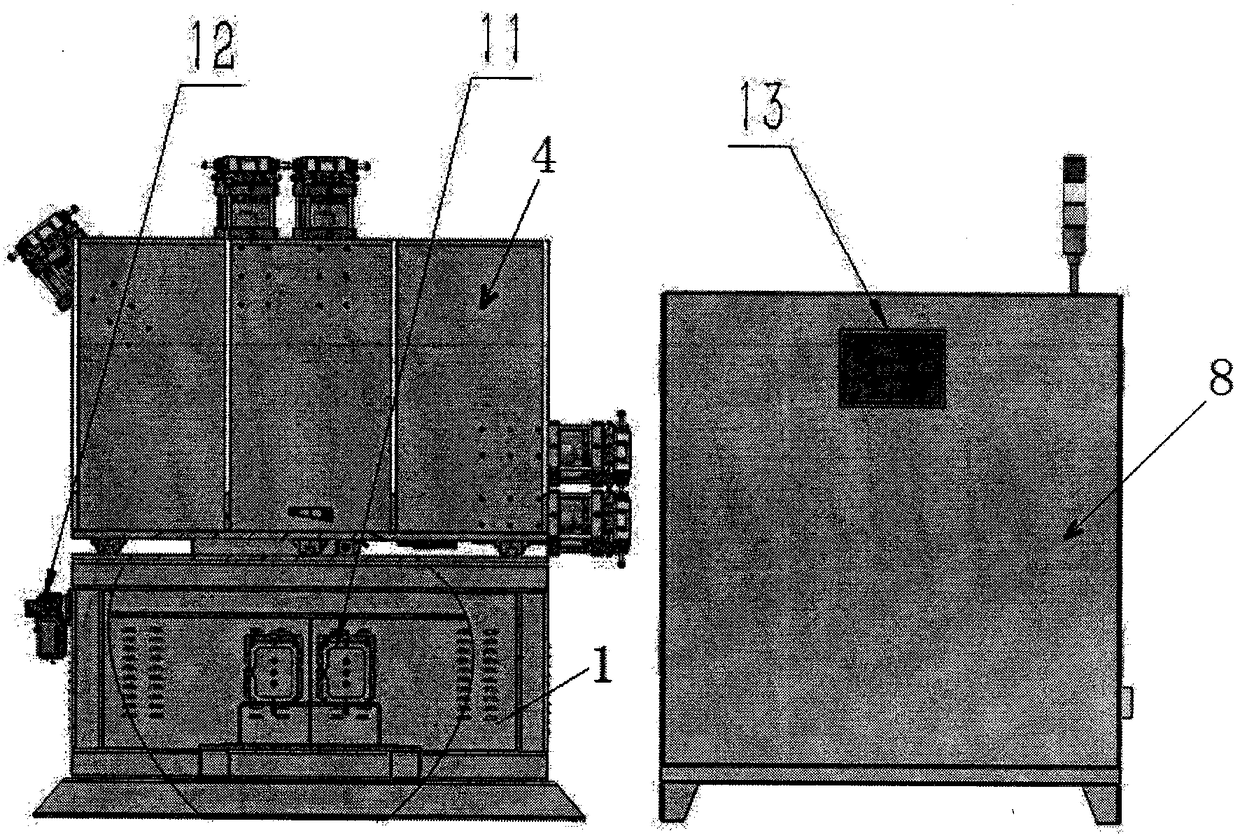

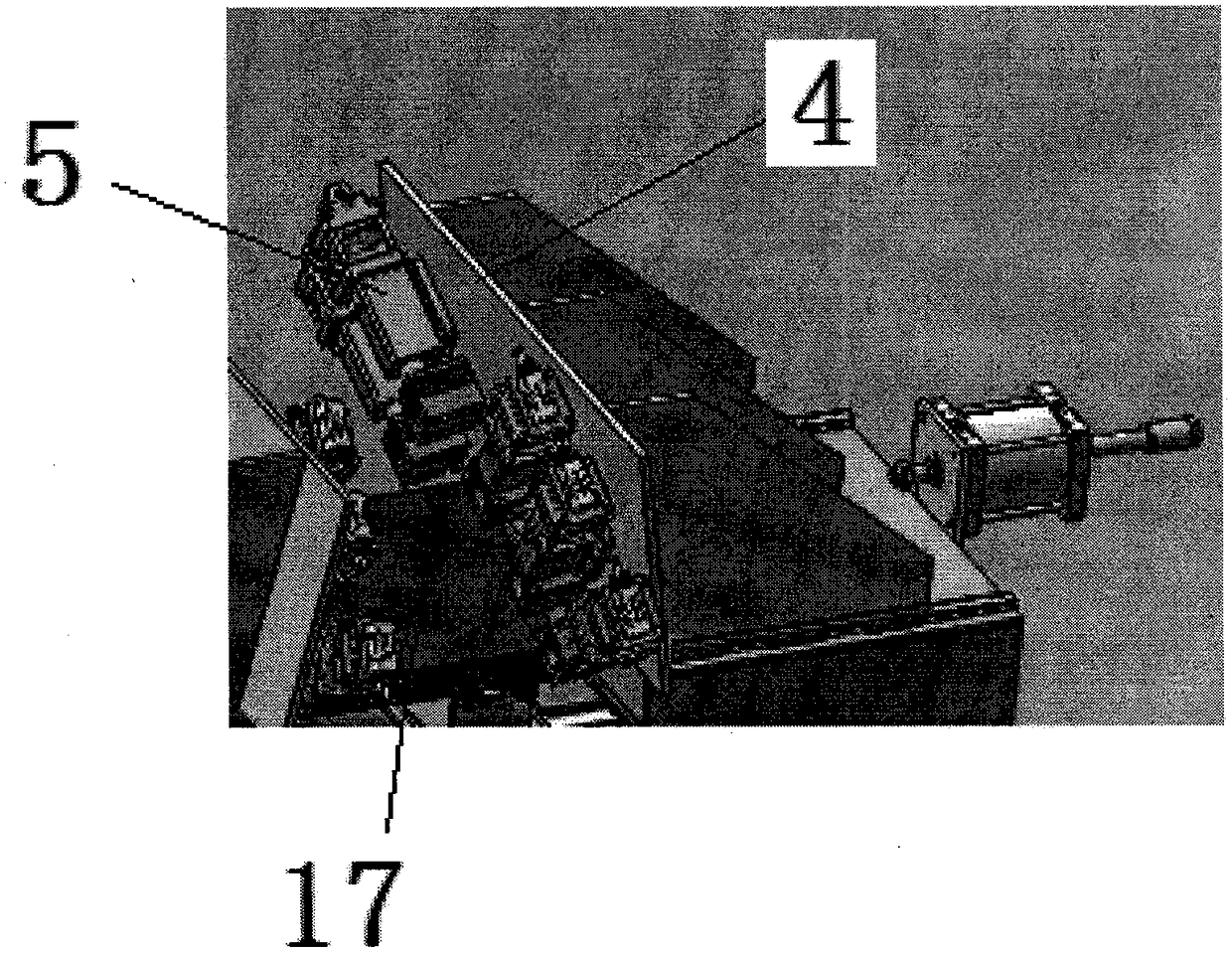

[0004] The main chassis 1 is installed on the main chassis foot 101, and each of the two ends of the main chassis 1 has a symmetrical box A, and the middle part of the main chassis 1 has two symmetrical boxes B, and the two symmetrical boxes B share one The table top C and the top surface of the two symmetrical boxes A are equipped with a guide rail 2. The guide rail 2 is used for the movement of the left welding assembly 3 and the right welding assembly 4 in the rails, and pushes the cylinder 7 to connect with the left welding assembly 3 and the right welding assembly 4. The left welding assembly 3 and the right welding assembly 4 are driven by the push cylinder 7 to move forward or backward in the guide rail 2. Five welding cylinders 5 are respectively installed on the vertical surfaces opposite the left welding assembly 3 and the right welding assembly 4. The welding cylinders 5 can be used for front and rear horizontal telescopic movement, and the welding cylinder 5 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com