Method for drying honeycomb molded body and method for manufacturing honeycomb structure

A drying method and molding technology, which can be used in manufacturing tools, ceramic molding machines, etc., can solve the problems of increased man-hours, difficult production, and reduced productivity of honeycomb structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] First, as a ceramic raw material, a cordierite material obtained by mixing alumina, kaolin, and talc is used, and a binder containing an organic binder, a pore-forming material, and water (73% by mass) as a dispersion medium are mixed. Mixing to obtain clay.

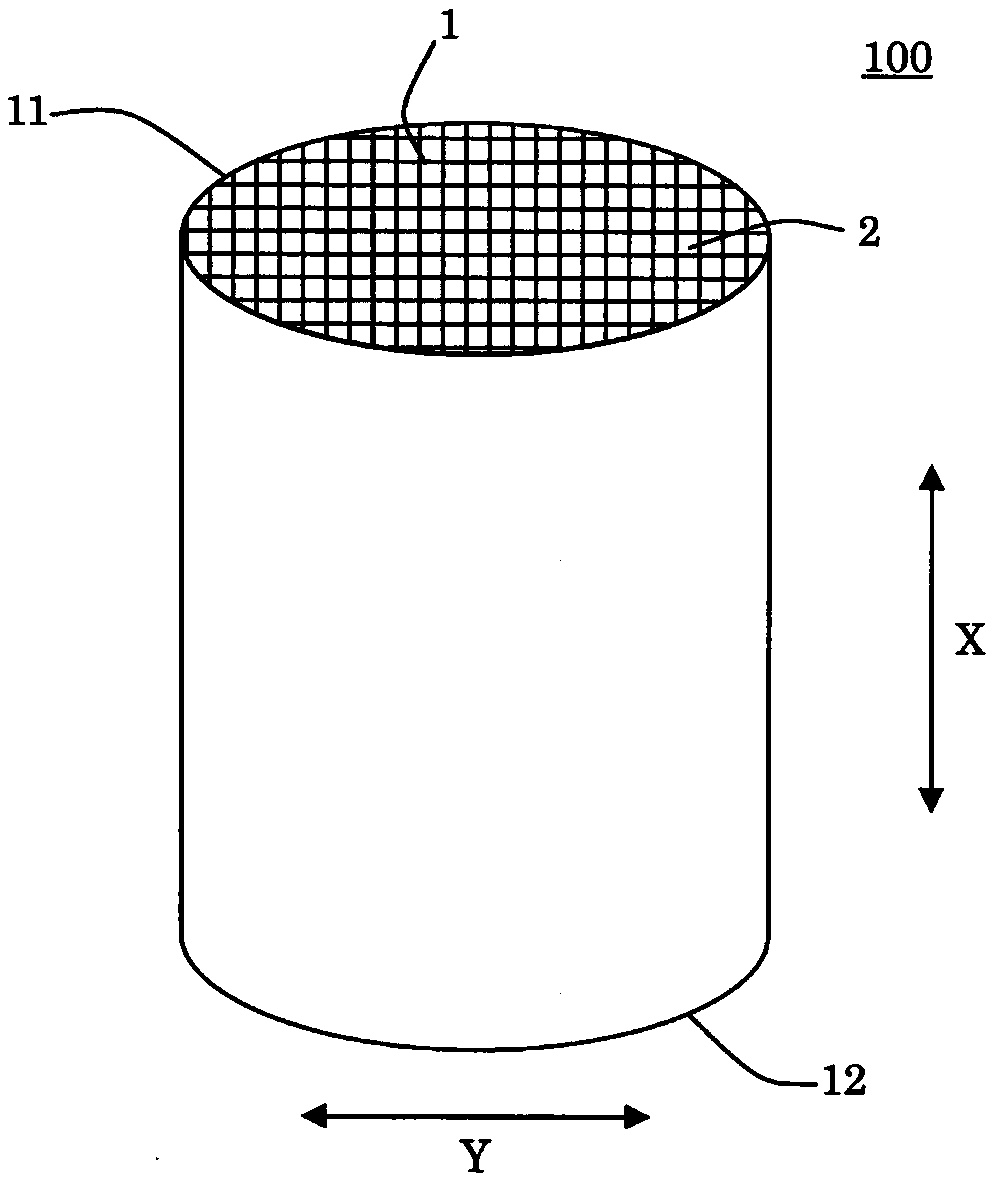

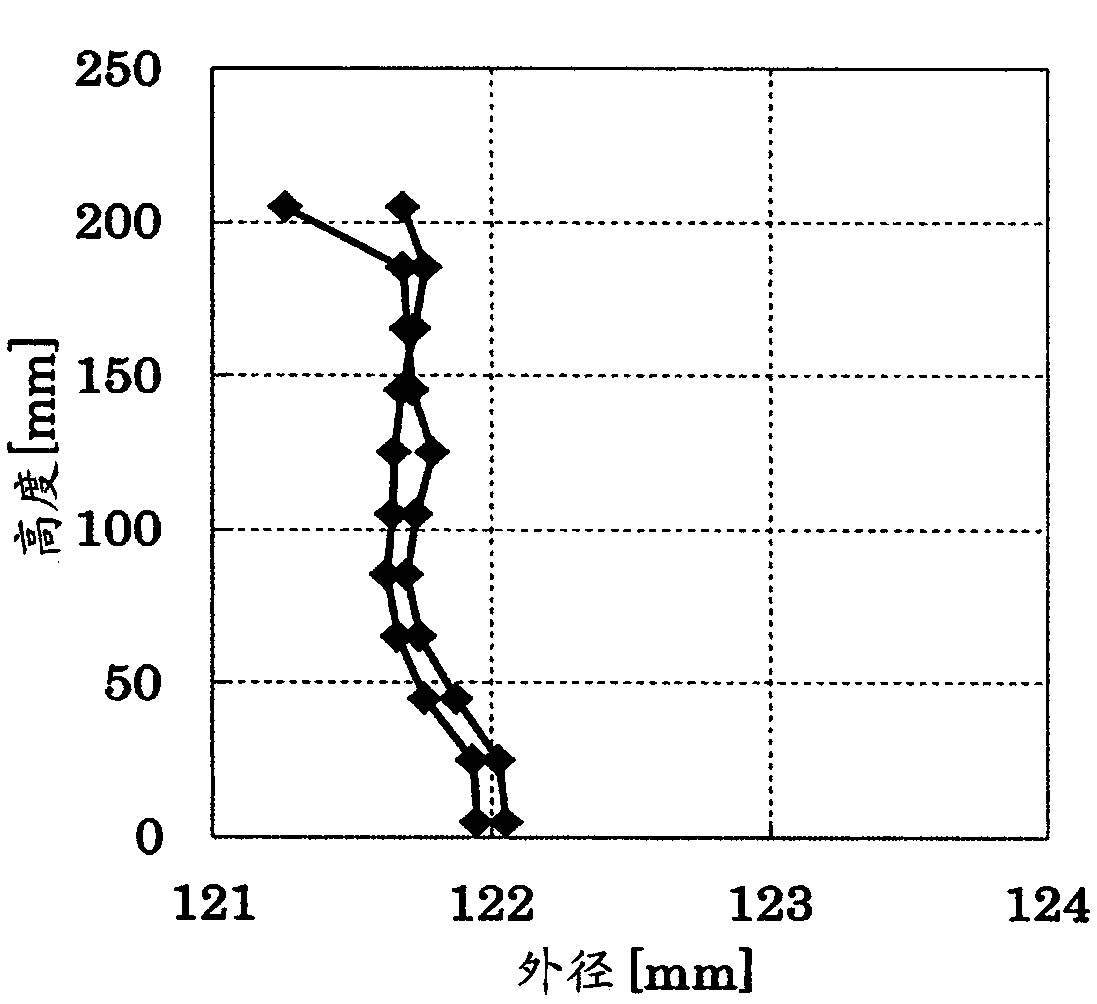

[0057] The obtained clay was extrusion-molded to obtain an unfired honeycomb formed body having cells having a square cross-sectional shape orthogonal to the direction in which the cells extend. For this unfired honeycomb formed body, the diameter ( figure 1 The maximum length in the Y direction in) is 126mm, and the length (the length in the direction in which the compartment extends ( figure 1 The length in the X direction in )) is 220 mm, and the outer shape is cylindrical.

[0058] For the obtained unfired honeycomb formed body, the moisture content is 42%, and the cell density is 40 cells / cm 2 , The thickness of the compartment wall is 210μm, and the mass is 1250g. Two unfired honeycomb formed bodies like this we...

Embodiment 2~5

[0068] (Examples 2 to 5, Comparative Examples 1 to 4)

[0069] Except for changing the conditions shown in Table 1 and Table 2, in the same manner as in Example 1, the unfired honeycomb formed body was dried. The results in this drying method are shown in Table 1 and Table 2.

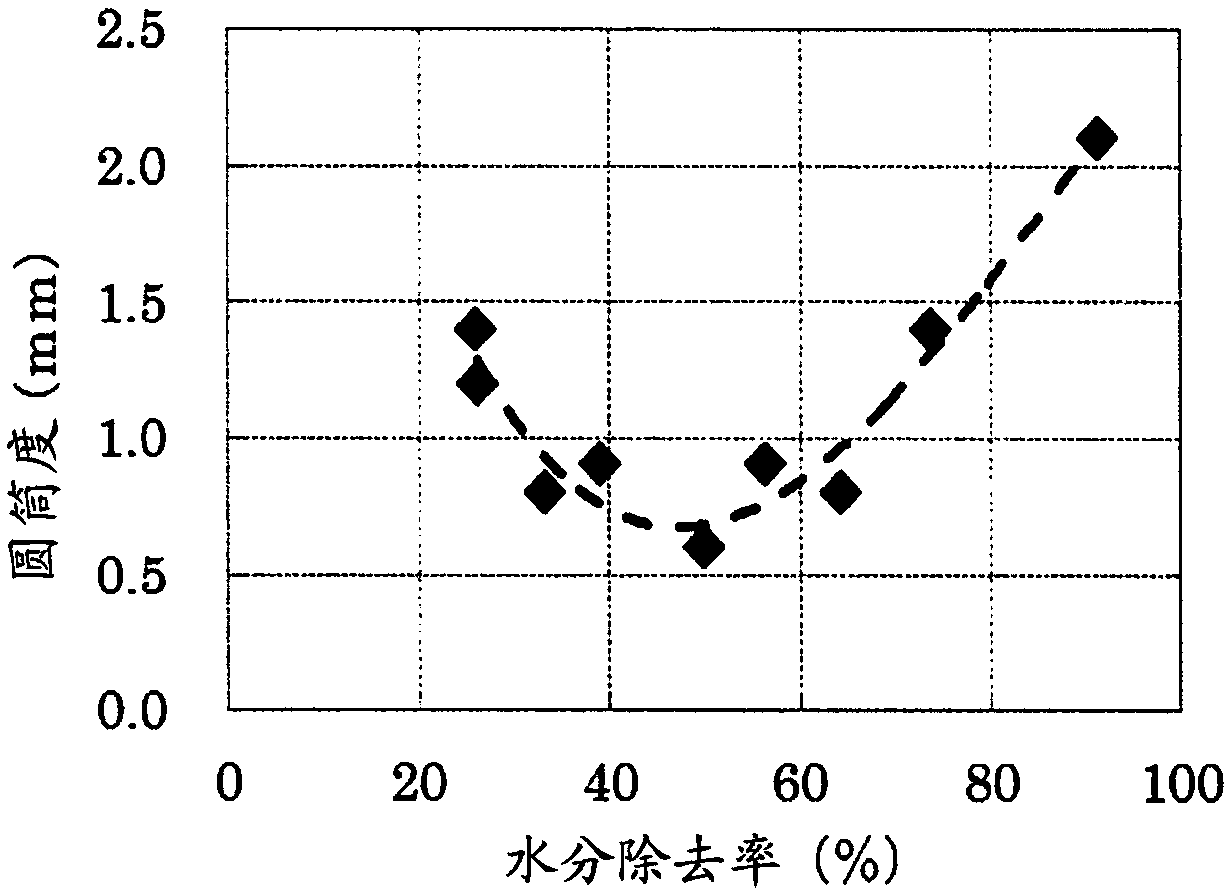

[0070] In Examples 4 and 5, the moisture content of the unfired honeycomb molded body was 23%. In addition, in Comparative Example 2, the same honeycomb formed body as the unfired honeycomb formed body used in Example 1 was used, and the unfired honeycomb formed body was obtained before drying. 26% of all moisture contained before drying was removed. The dry honeycomb molded body. In this comparative example 2, when the induction drying process entered the microwave drying process, the honeycomb formed body was cracked. In addition, "crack" refers to a state where a part of the partition wall of the honeycomb formed body is cracked.

[0071] In addition, in Examples 2 to 5 and Comparative Examples 1 to 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com