Multiplex output power supply

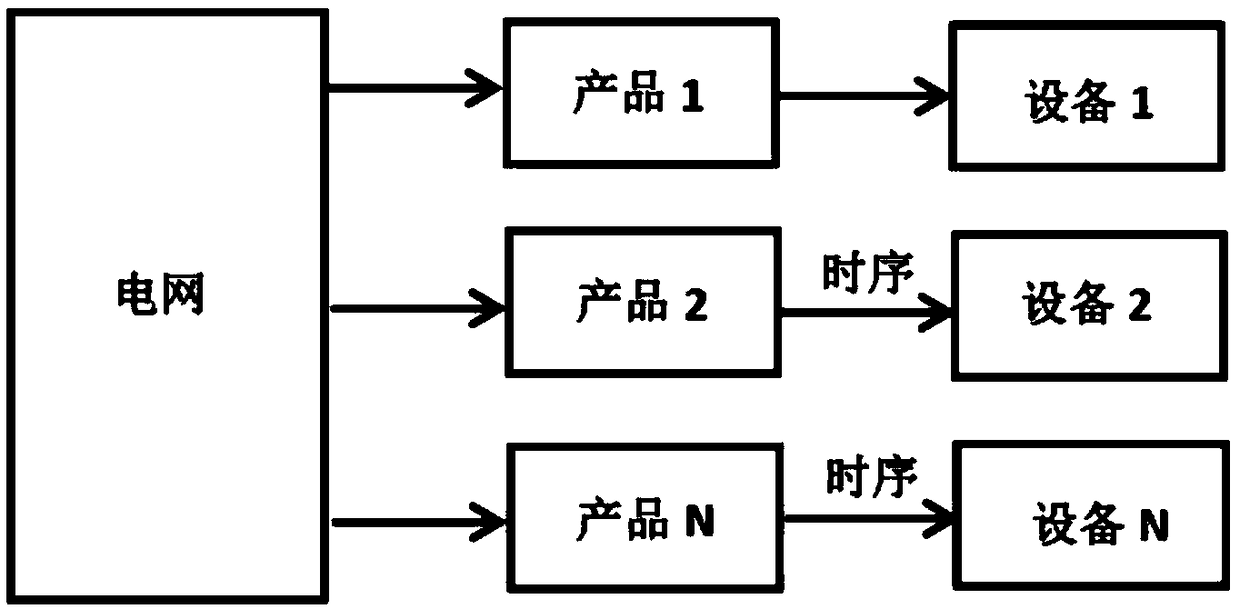

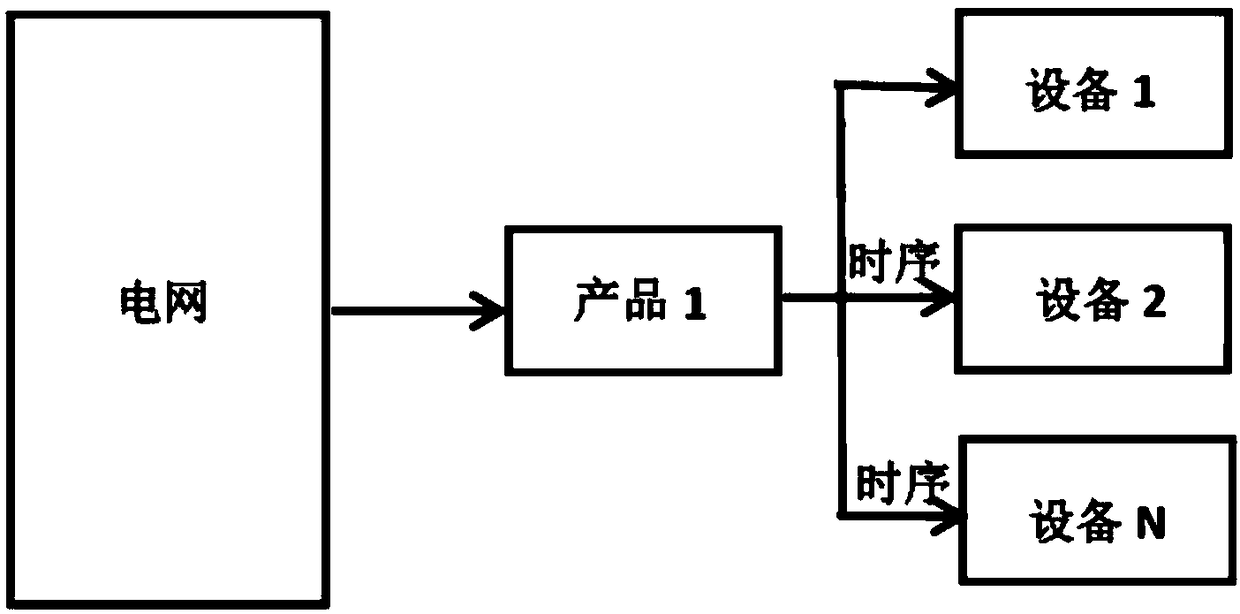

A multi-channel output and power supply technology, which is applied in the direction of output power conversion devices, electrical components, DC power input conversion to DC power output, etc., can solve problems such as high cost, unsatisfactory customer timing applications, and large space occupation, etc., to achieve Low cost, easy design, and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

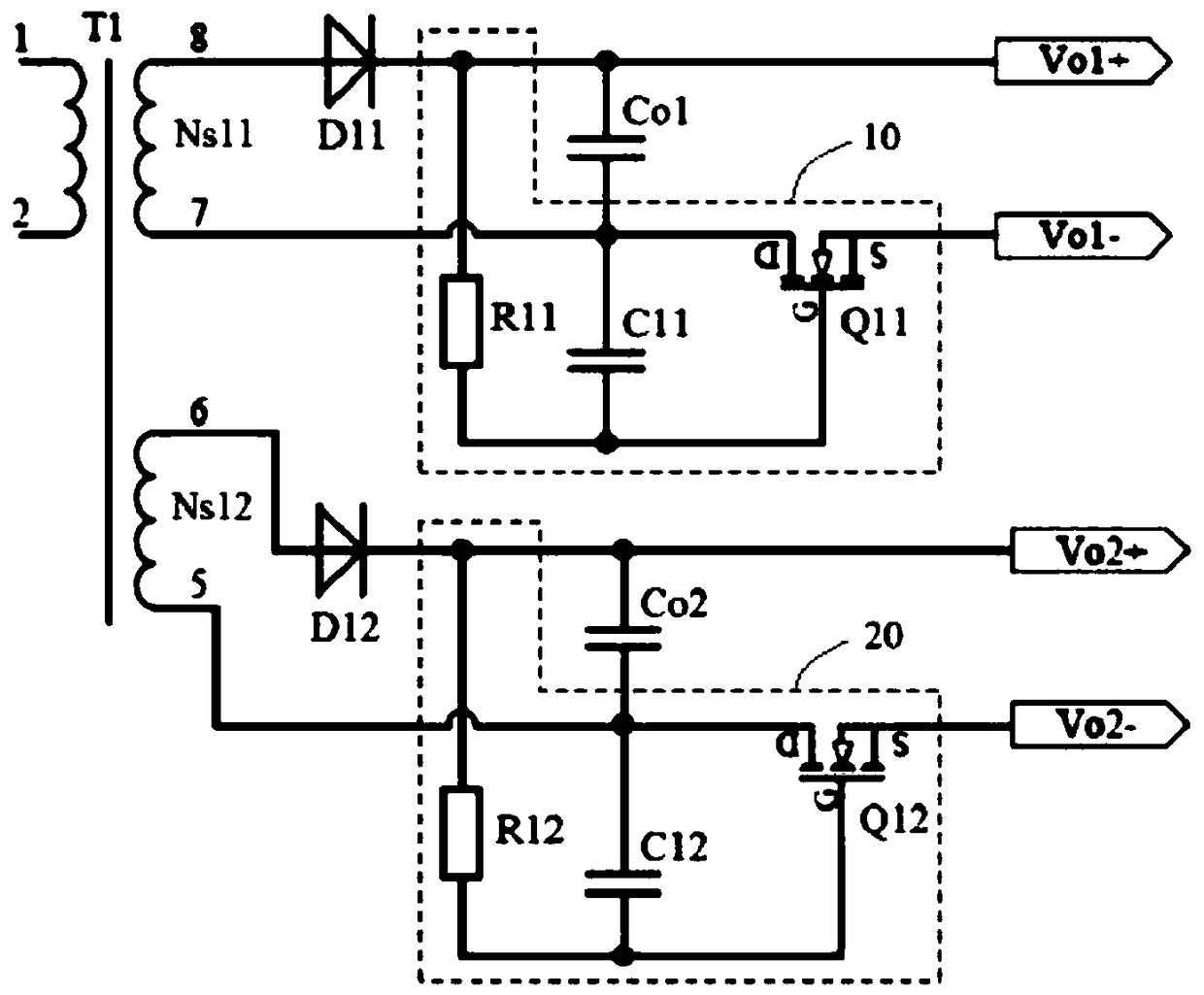

[0027] Such as image 3 As shown, it is a schematic diagram of the multi-output power supply of the first embodiment of the present invention. A multi-output power supply includes at least two secondary windings of transformers, and one secondary winding forms the main output circuit (hereinafter referred to as the main output circuit). circuit), other secondary windings form an auxiliary output circuit (hereinafter referred to as auxiliary circuit), and the timing control circuit 10 of the main output circuit and the timing control circuit 20 of the auxiliary output circuit can be set as required to realize the multi-channel equipment in the application system. Time-sequential power supply is required; there may also be only the timing control circuit 10 of the main output circuit or the timing control circuit 20 of the auxiliary output circuit. The timing control circuit has the same structure in the main and auxiliary output circuits. The timing control circuit 10 of the ma...

no. 2 example

[0043] Such as Figure 4 As shown, it is a schematic diagram of the multi-output power supply of the second embodiment of the present invention. A multi-output power supply is different from the first embodiment in that a stable capacitor is connected in series between the positive electrode of the capacitor C1 and the driving pin of the MOS transistor Q1. Voltage tube Z1; that is, the voltage regulator tube Z1 is connected in series between the gate of the MOS transistor Q1 and the connection end of the resistor R1 and the capacitor C1, the anode of the voltage regulator tube Z1 is connected to the grid of the MOS tube Q1, and the cathode of the voltage regulator tube Z1 Connect one end of the resistor R1 and the other end of the capacitor C1 respectively.

[0044] Now take the timing control circuit of the main output circuit as an example to illustrate its connection relationship as follows: the timing control circuit includes MOS tube Q11, resistor R11, capacitor C11 and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com