Supporting plate jetting combustion device with pulsed ignition source and ignition method

A technology of combustion device and high-voltage pulse power supply, which is applied to combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of flame stability being easily disturbed by airflow, the energy of ignition source is small, and it is difficult to achieve ignition, so as to ensure flame connection and stability. , Low energy consumption of pulse discharge, the effect of promoting flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

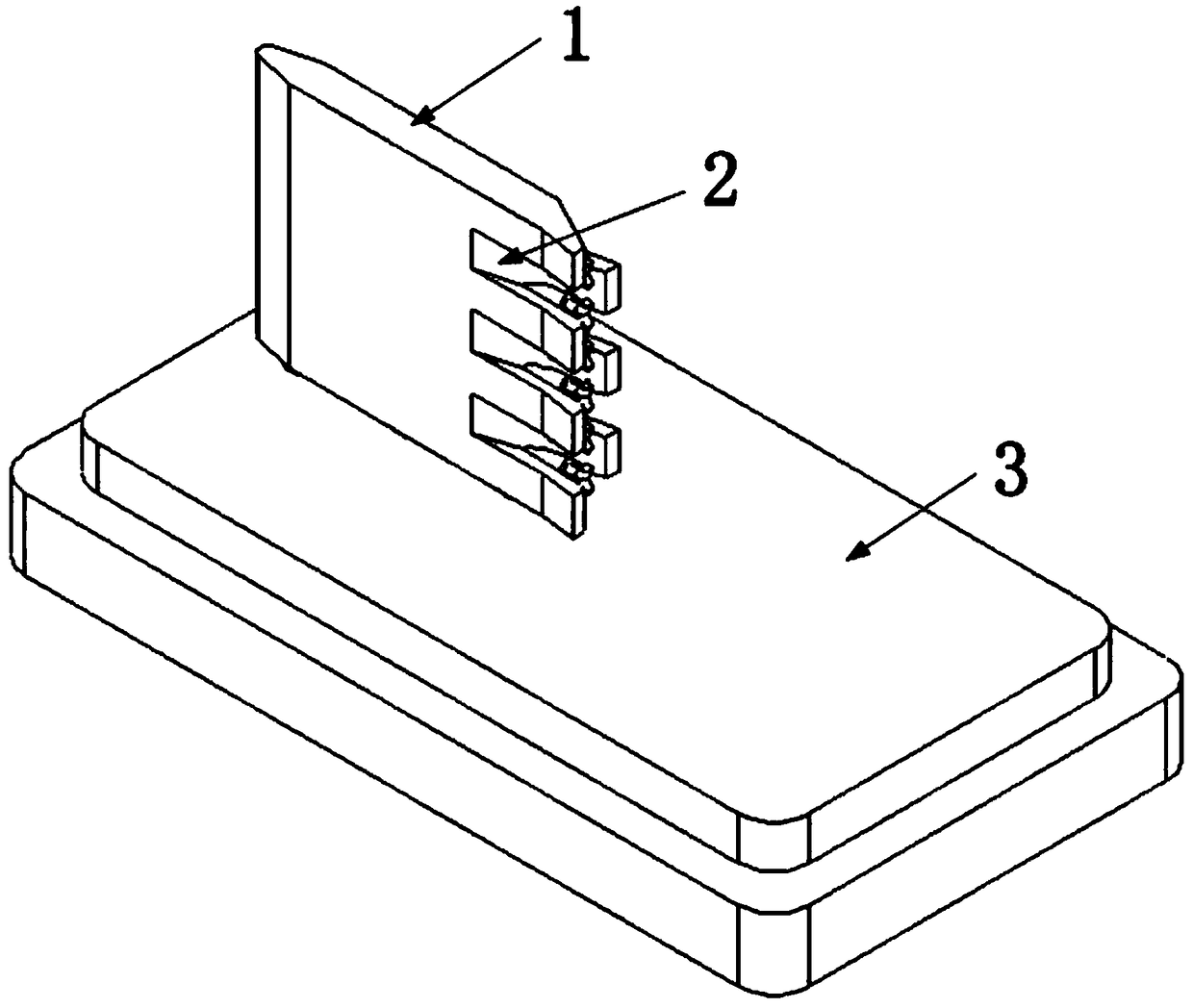

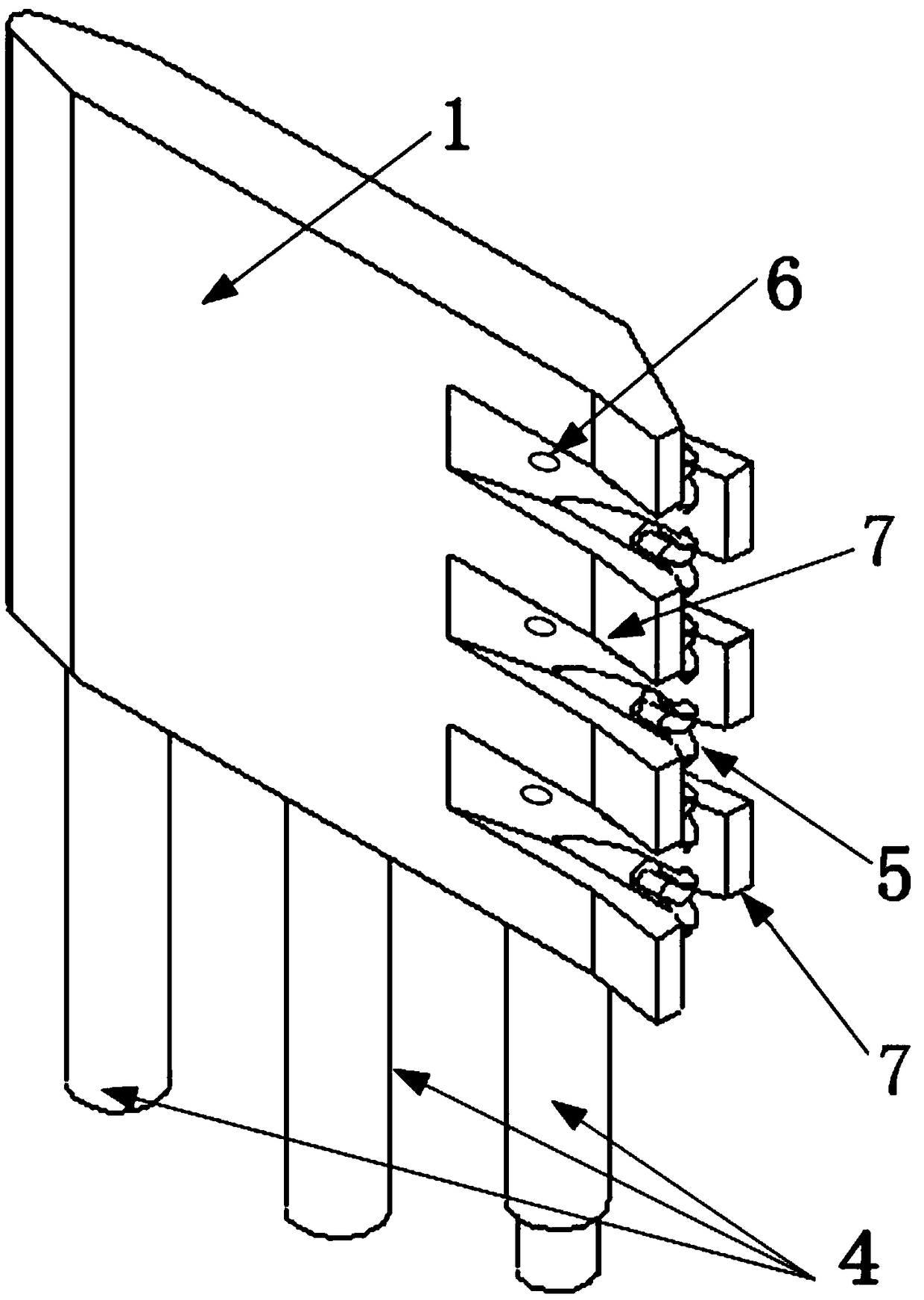

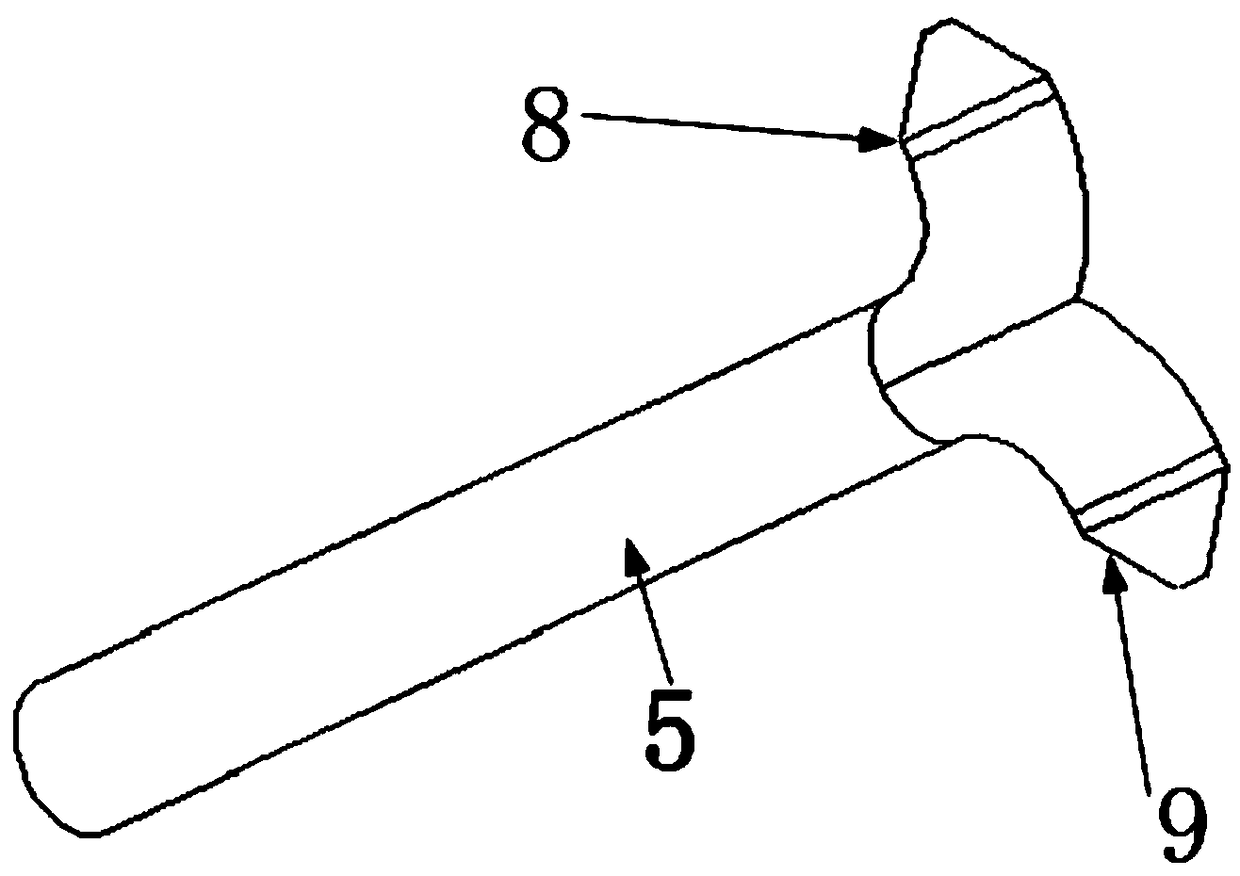

[0031] The invention provides a support plate injection combustion device provided with a pulse ignition source, such as figure 1 and figure 2 As shown, it includes a support plate fixing panel 3, the support plate fixing panel 3 is provided with a support plate body 1, the tail portion 2 of the support plate body is a tail edge staggered structure, and the tail portion 2 of the support plate body is respectively provided with An array type ignition electrode and a plurality of fuel injection holes 6, the array type ignition electrode is electrically connected with a high voltage pulse power supply.

[0032] In the present invention, the array type ignition e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com