Anti-damp floor and manufacturing method thereof

A manufacturing method and floor technology, which are applied in building construction, non-polymer adhesive additives, adhesive types, etc., can solve problems such as affecting the comfort and aesthetic effect of the floor, reducing the comfort of the feet, and cumbersome processes. , to achieve the effect of super biodegradability, simplify production process and improve environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

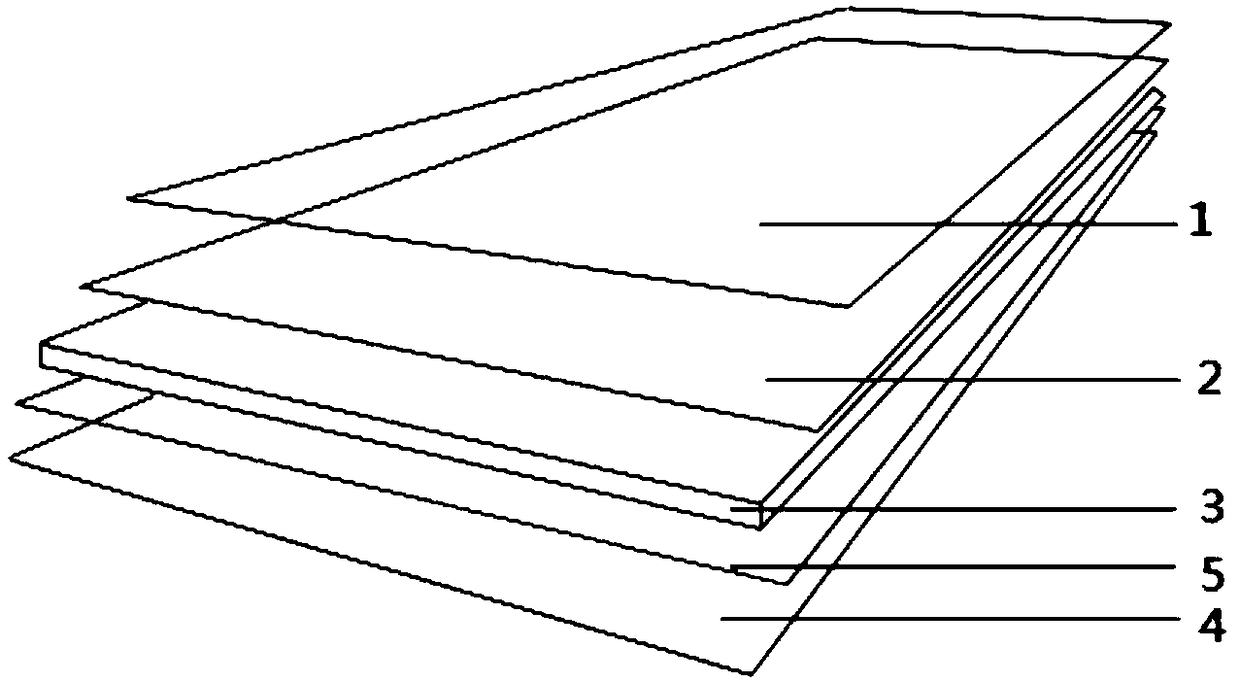

[0026] A moisture-proof floor, which comprises, from top to bottom, a protective wear-resistant layer 1, a decorative layer 2 with an aesthetic effect, a supporting base material layer 3, and a balance layer 4 with moisture-proof and anti-deformation effects. The grinding layer 1 is a transparent paint layer containing 3% nano-aluminum oxide with a thickness of 0.05-2.00 mm; the decorative layer 2 is made of PVC color film paper, and the base material layer 3 is eucalyptus plywood. The balance layer 4 is a veneer; the decorative layer 2 and the base layer 3 are bonded with a two-component polyurethane resin adhesive, and a layer of thermoplastic resin is also arranged between the base layer 3 and the balance layer 4. The waterproof layer 5 formed by the adhesive.

[0027] The preparation method of the two-component polyurethane resin adhesive is as follows: 90 mass parts of isocyanate and 70 mass parts of polyvinyl acetate emulsion are used as two-component components, 10 mass...

Embodiment 2

[0037] A moisture-proof floor, which comprises, from top to bottom, a protective wear-resistant layer 1, a decorative layer 2 with an aesthetic effect, a supporting base material layer 3, and a balance layer 4 with moisture-proof and anti-deformation effects. The grinding layer 1 is a transparent paint layer containing a mass fraction of 5% nano-alumina, with a thickness of 0.05-2.00 mm; the decorative layer 2 is made of PVC color film paper, and the base material layer 3 is poplar plywood. The balance layer 4 is a veneer; the decorative layer 2 and the base layer 3 are bonded with a two-component polyurethane resin adhesive, and a layer of thermoplastic resin is also arranged between the base layer 3 and the balance layer 4. The waterproof layer 5 formed by the adhesive.

[0038] The manufacture method of described two-component polyurethane resin adhesive is as follows: by the isocyanate of 90 mass parts and the polyvinyl acetate emulsion of 70 mass parts as two-component co...

Embodiment 3

[0048] A moisture-proof floor, which comprises, from top to bottom, a protective wear-resistant layer 1, a decorative layer 2 with an aesthetic effect, a supporting base material layer 3, and a balance layer 4 with moisture-proof and anti-deformation effects. The grinding layer 1 is a transparent paint layer containing a mass fraction of 2% nano-alumina, with a thickness of 0.05 to 2.00 mm; the decorative layer 2 is made of PVC color film paper, and the base material layer 3 is poplar plywood. The balance layer 4 is a veneer; the decorative layer 2 and the base layer 3 are bonded with a two-component polyurethane resin adhesive, and a layer of thermoplastic resin is also arranged between the base layer 3 and the balance layer 4. The waterproof layer 5 formed by the adhesive.

[0049] The manufacture method of described two-component polyurethane resin adhesive is as follows: by the isocyanate of 95 mass parts and the polyvinyl acetate emulsion of 50 mass parts as two-component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com