Processing method for enabling cellulose fibers to have anti-inflammatory function based on super-critical CO2 fluid technology

A technology of cellulose fiber and fluid technology, which is applied in the processing field of cellulose fiber with anti-inflammatory function based on supercritical CO2 fluid technology, and can solve the problems of relatively small content of functional content, complicated finishing process, and single function. Achieve good sustained-release effect, good hand feeling, and increase effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Supercritical CO 2 Method for fluid loading of anti-inflammatory drug tea polyphenols to viscose fibers

[0034] Firstly, the viscose fabric was washed with ethanol and deionized water, dried and balanced for 24 hours and weighed. The tea polyphenols were weighed according to 7.5% of the weight of the viscose fabric, and 20% ethanol solution was prepared with water, and then 0.04mol / L AOT was prepared. / ethanol solution, put into a clean container to prepare a microemulsion.

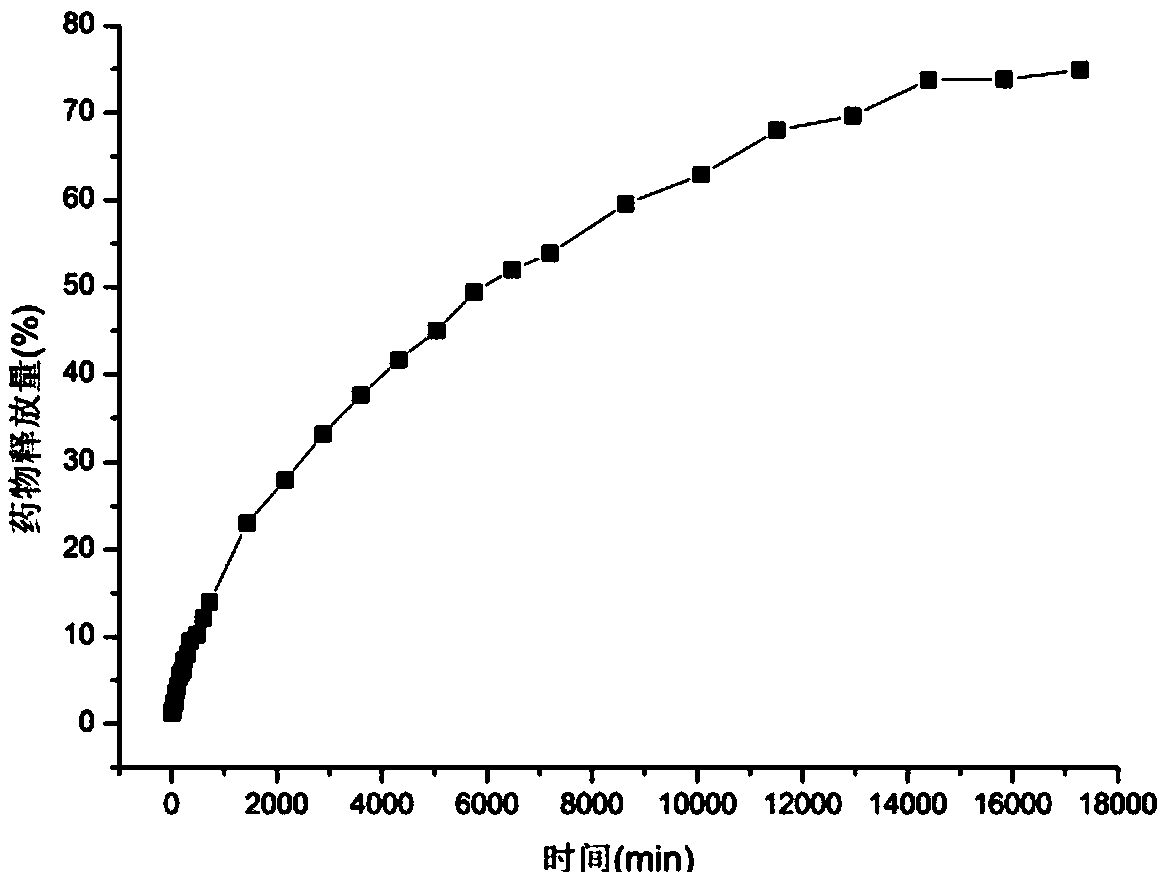

[0035] Put the prepared microemulsion into the medicine tank of the high pressure equipment, and then put the viscose fabric. Cool the CO with a cooling tank 2 Gas CO flowing out of the cylinder 2 Cooled into liquid, the pressure of high-pressure equipment is set to 19MPa, the temperature is 60℃, CO 2 Converted to supercritical fluid, after immersion equilibrium for 4.5H, the experiment ended, and the viscose fiber loaded with tea polyphenols was obtained. The drug loading of visco...

Embodiment 2

[0039] Example 2: Supercritical CO 2 Method of fluid loading anti-inflammatory drug indoleacetic acid to hemp fibers

[0040] Weigh an appropriate amount of hemp fiber, prepare a water-containing ionic liquid 1-butyl-3-methylimidazolium chloride as a solution, the moisture content is 2%, and immerse the hemp cellulose fiber in it, the bath ratio range is 1:25, set The temperature was 65°C and the time was 30min. After finishing, the hemp fiber was taken out.

[0041] Wash the pre-swollen hemp fiber with ethanol and deionized water, dry it and balance it for 24 hours, weigh it, weigh 8.5% indole acetic acid according to the weight of the hemp fiber, prepare a 40% ethanol solution with water, and then prepare 0.06mol / L AOT / ethanol solution, put into a clean container to prepare a microemulsion.

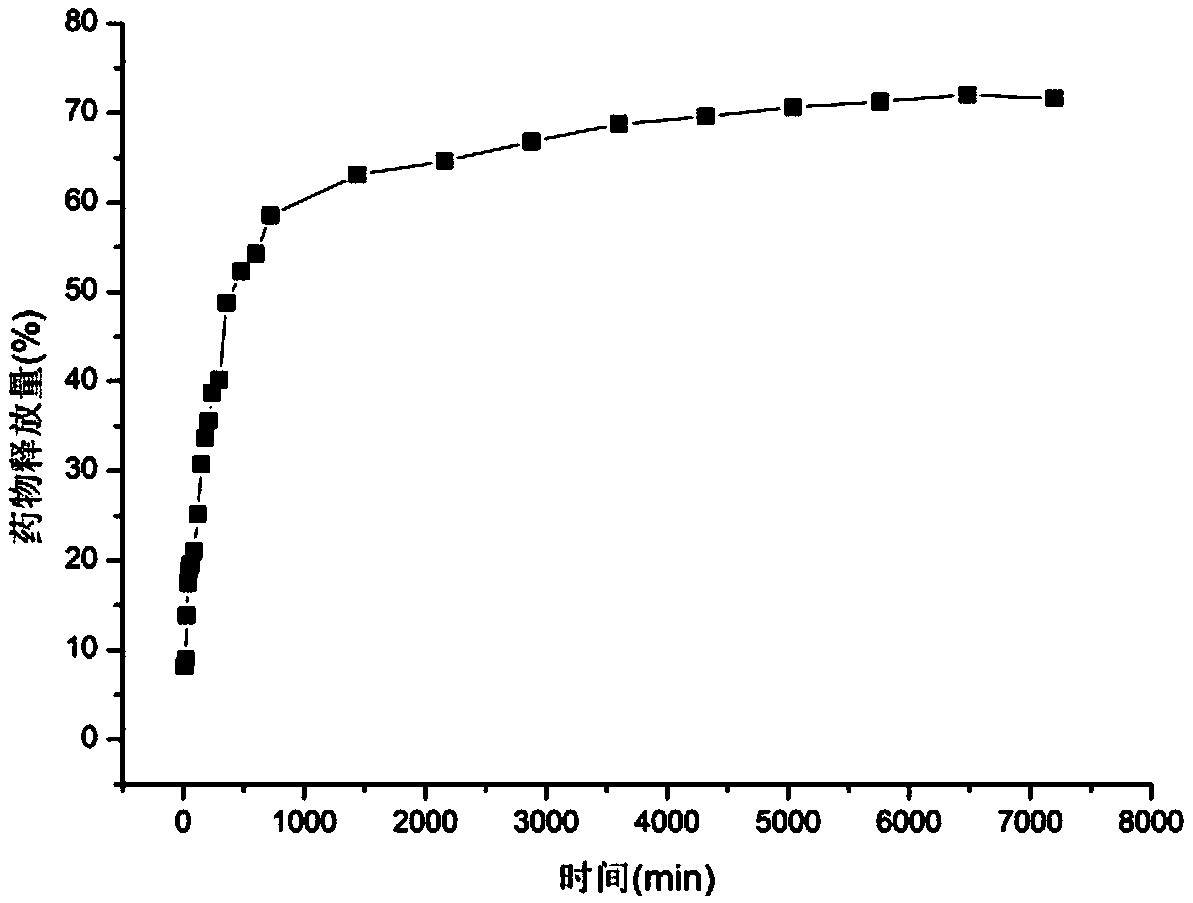

[0042] Put the prepared microemulsion into the medicine tank of the high-pressure equipment, and then put the hemp fiber. The carbon dioxide gas flowing out of the carbon dioxide cy...

Embodiment 3

[0046] Example 3: Supercritical CO 2 Method of fluid loading anti-inflammatory drug perillyl alcohol to modal fibers

[0047] First, take an appropriate amount of modal fabric, wash it with ethanol and deionized water, dry it for 24 hours and weigh it, weigh 7.5% perillyl alcohol according to the weight of the modal fabric, put it into the medicine tank of the high-pressure equipment, and add 0.1% of the weight of the modal fabric. of acetone, and then into the modal fabric. The gaseous carbon dioxide flowing out of the carbon dioxide cylinder is cooled into a liquid with a cooling tank.

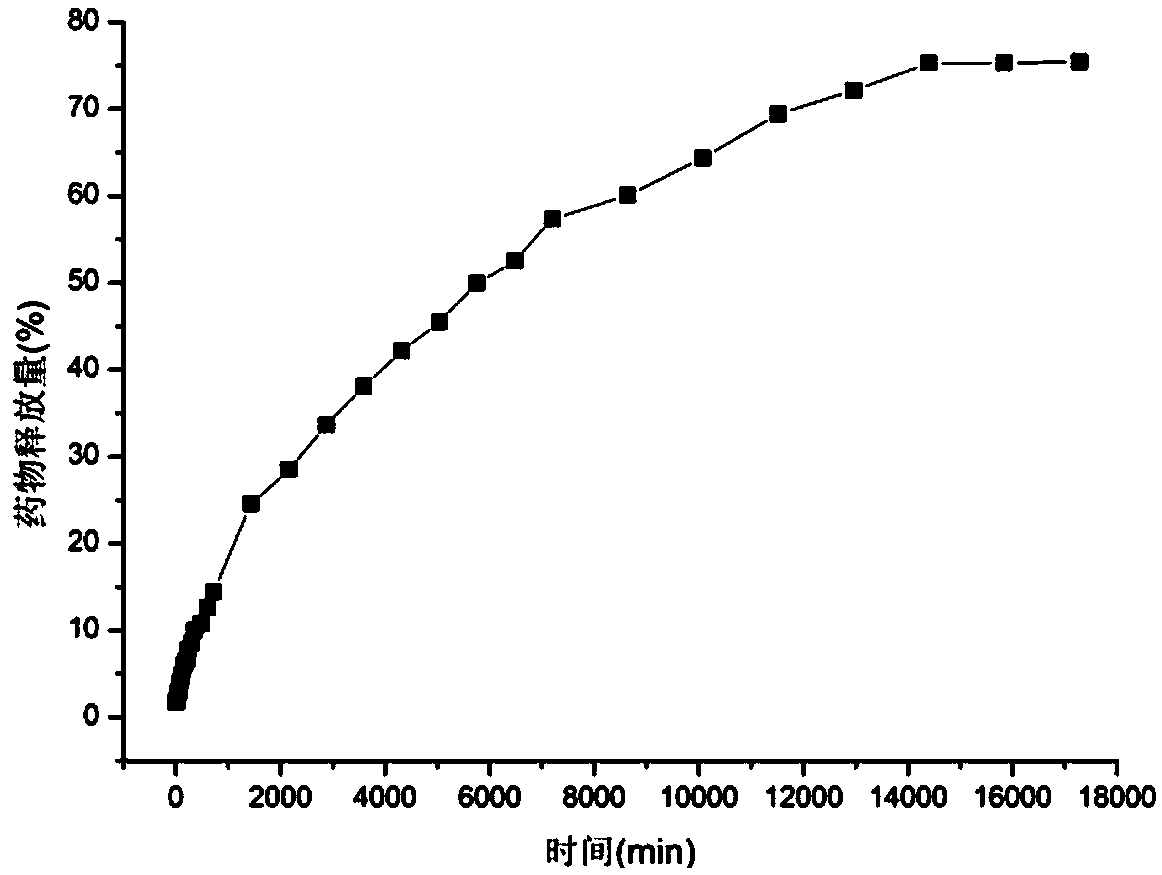

[0048] The pressure of the high-pressure equipment is first set to 12Mpa, the temperature is 35°C, and the carbon dioxide becomes a supercritical fluid. After immersion and equilibrium for 25min, the pressure rises to 26MPa at a rate of 0.6MPa / min; Descending until the end of the experiment yielded modal fibers loaded with anti-inflammatory perilloid alcohols. The modal fiber drug loading...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com