A supercritical co 2 Fluid technology makes cellulose fiber have slimming function processing method

A technology of cellulose fiber and fluid technology, which is applied in the processing field based on supercritical CO2 fluid technology to make cellulose fiber have a slimming function. Good hand feeling, good sustained-release effect, and effect of increasing effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Supercritical CO 2 Method of Fluid Loading the Slimming Drug Theophylline to Tencel Fiber

[0035] First, wash the Tencel fabric with ethanol and deionized water, dry and balance for 24 hours, weigh theophylline according to 9% of the weight of the Tencel fabric, prepare a 45% ethanol solution with water, and then prepare a 0.06 mol / L AOT / Ethanol solution, put into a clean container to prepare microemulsion.

[0036] Put the prepared microemulsion into the medicine tank of the high-pressure equipment, and then put it into the Tencel fabric. Use a cooling tank to cool the gaseous carbon dioxide flowing out of the carbon dioxide cylinder into a liquid. The pressure of the high-pressure equipment is set at 25Mpa, the temperature is 75°C, and the carbon dioxide becomes a supercritical fluid. After 2.0 hours of impregnation equilibrium, the experiment is over, and the Tencel loaded with theophylline is obtained. fiber. The drug loading of Tencel fiber is 7.8%....

Embodiment 2

[0040] Example 2: Supercritical CO 2 Method of Fluid Loading Slimming Drug Nuciferine to Hemp Fiber

[0041] Weigh an appropriate amount of hemp fiber, soak it in an aqueous solution of N-methylmorpholine-N-oxide (NMMO) with a mass fraction of 65% for 75 minutes at a bath ratio of 1:25, and take out the hemp fiber at a water bath temperature of 85°C. .

[0042] After the hemp fiber is washed with ethanol and deionized water, it is dried and weighed for 24 hours, and the nuciferine is weighed according to 8.5% of the weight of the hemp fiber and put into the medicine tank of the high-pressure equipment, and then put into the hemp fiber. Use a cooling tank to cool the gaseous carbon dioxide flowing out of the carbon dioxide cylinder into a liquid. The pressure of the high-pressure equipment is set to 28Mpa, the temperature is 65°C, and the carbon dioxide becomes a supercritical fluid. After 50 minutes of impregnation and balance, the experiment ends, and hemp fibers loaded with...

Embodiment 3

[0046] Example 3: Supercritical CO 2 Method of Fluid Loading the Slimming Drug Theophylline Acetate to Viscose Fiber

[0047] First wash the viscose fabric with ethanol and deionized water, dry and balance for 24 hours and weigh, take theophylline acetic acid by weighing 11.5% of the viscose fabric weight and put it into the medicine tank of the high-pressure equipment, and add 0.12% viscose fabric weight % methanol, then put into the viscose fabric. Cool the CO 2 The gas CO flowing out of the cylinder 2 Cool to liquid.

[0048] The pressure of the high-pressure equipment is first set to 8Mpa, the temperature is 80°C, and the carbon dioxide becomes a supercritical fluid. After impregnating and balancing for 20 minutes, the pressure rises to 30MPa at a speed of 0.5MPa / min; Descending until the end of the experiment yielded viscose fibers loaded with the weight-loss drug theophylline acetate. The drug loading of viscose fiber was 7.2%.

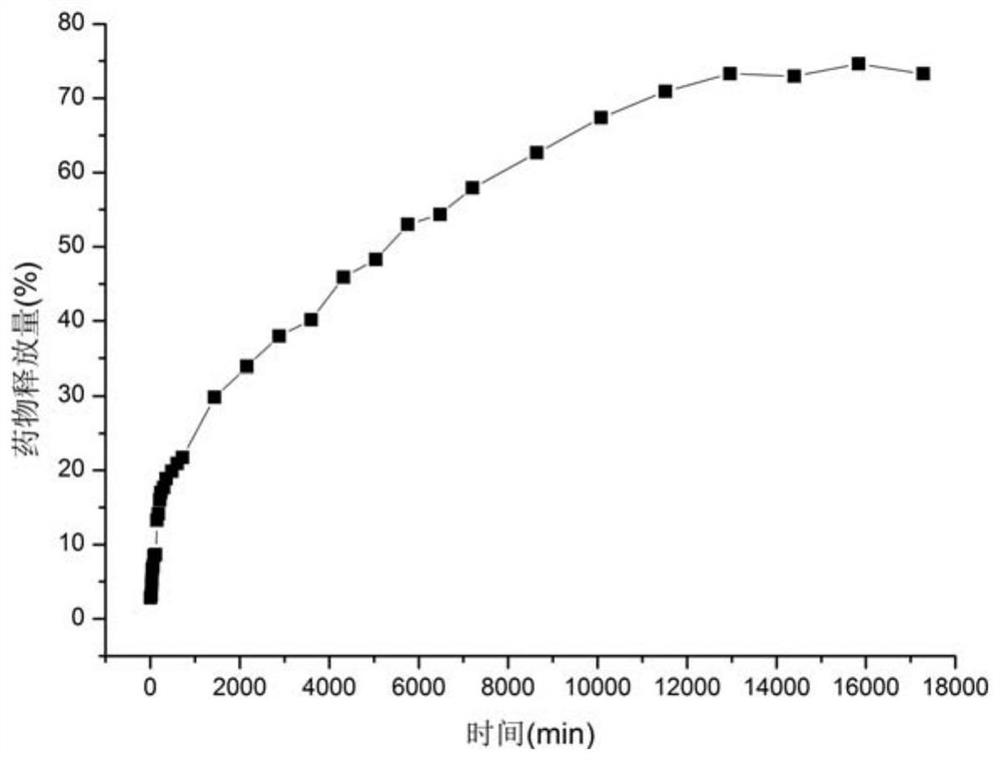

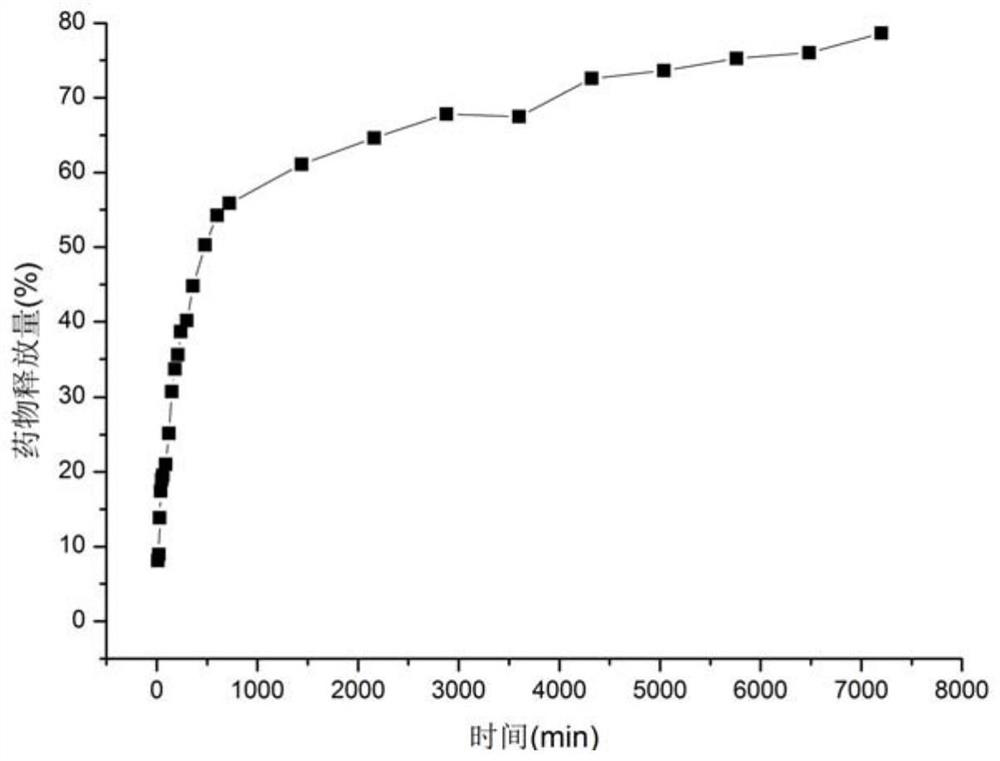

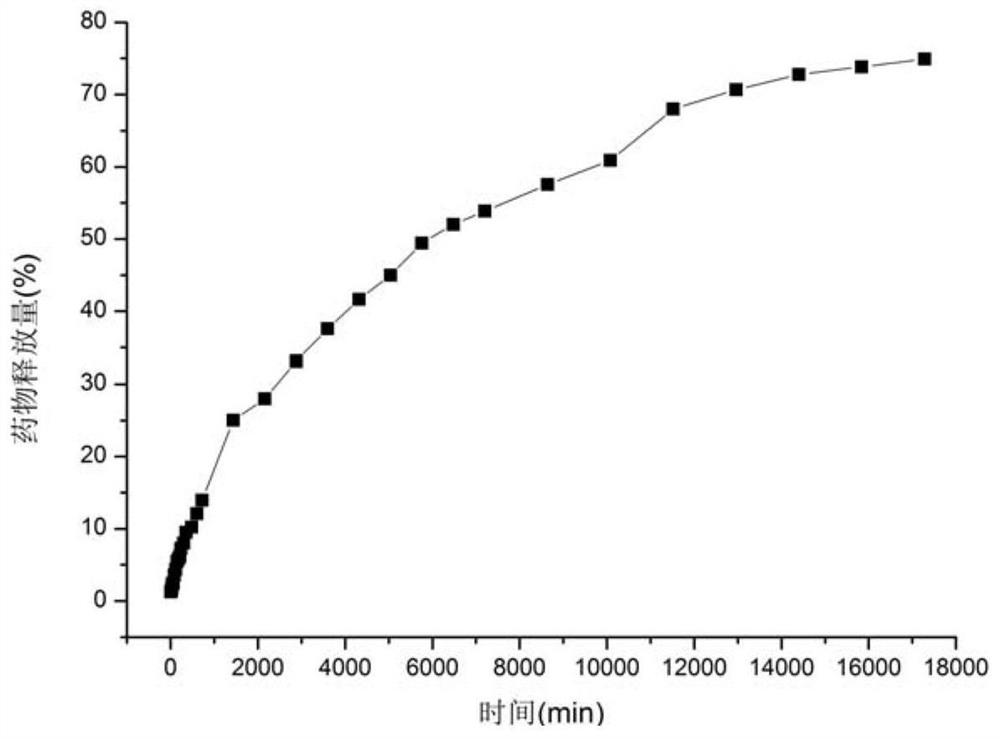

[0049] In order to analyze the slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com