Preparation method of handwash tableware detergent containing sodium xylene sulfonate

A technology of sodium xylene sulfonate and tableware detergent, which is applied in the field of preparation of hand-washed tableware detergent, can solve problems such as grease difficulty and water pollution, achieve good oil absorption effect, improve structural stability, and good oil removal and oil absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

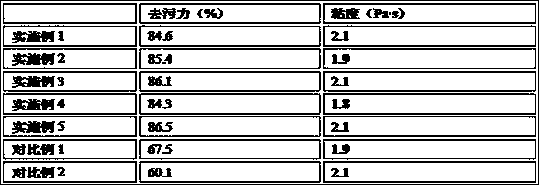

Examples

Embodiment 1

[0015] A preparation method of a dishwashing detergent for hand washing containing sodium xylene sulfonate, comprising the following steps:

[0016] S1. Grind the defatted rice bran, then add a buffer solution of disodium hydrogen phosphate and citric acid, then add xylanase, heat to 90°C, continue enzymatic hydrolysis for 20 minutes, then centrifuge at 2000r / min for 30 minutes, vacuum the precipitate Drying to obtain insoluble rice bran particles;

[0017] S2. Add activated clay and calcium oxide to water, the mass ratio of activated clay, calcium oxide and water is 1:1.5:20, stir at 60°C for about 5 h, filter, and dry the filter cake at 120°C for 2 h, Pulverize and cross 200 mesh sieves to obtain alkaline white clay;

[0018] S3. Disperse the alkaline clay in water, heat it to 60°C, then add hexadecyltrimethylammonium bromide dropwise to the alkaline clay dispersion under stirring, and then add chitosan, wherein Alkaline clay, cetyltrimethylammonium bromide and chitosan in...

Embodiment 2

[0022] A preparation method of a dishwashing detergent for hand washing containing sodium xylene sulfonate, comprising the following steps:

[0023] S1. Grind the defatted rice bran, then add a buffer solution of disodium hydrogen phosphate and citric acid, then add xylanase, heat to 100°C, continue enzymatic hydrolysis for 10 minutes, then centrifuge at 5000r / min for 10 minutes, vacuum the precipitate Drying to obtain insoluble rice bran particles;

[0024] S2. Add activated clay and calcium oxide to water, the mass ratio of activated clay, calcium oxide and water is 1:2.2:15, stir at 60°C for about 8 h, filter, and dry the filter cake at 120°C for 2 h, Pulverize and cross 200 mesh sieves to obtain alkaline white clay;

[0025] S3. Disperse the alkaline clay in water, heat it to 60°C, then add hexadecyltrimethylammonium bromide dropwise to the alkaline clay dispersion under stirring, and then add chitosan, wherein Alkaline clay, the mass ratio of cetyltrimethylammonium brom...

Embodiment 3

[0029] A preparation method of a dishwashing detergent for hand washing containing sodium xylene sulfonate, comprising the following steps:

[0030] S1. Grind the defatted rice bran, then add a buffer solution of disodium hydrogen phosphate and citric acid, then add xylanase, heat to 100°C, continue enzymatic hydrolysis for 15 minutes, then centrifuge at 3000r / min for 15 minutes, vacuum the precipitate Drying to obtain insoluble rice bran particles;

[0031] S2. Add activated clay and calcium oxide to water, the mass ratio of activated clay, calcium oxide and water is 1:1.5:20, stir at 60°C for about 7 h, filter, and dry the filter cake at 120°C for 2 h, Pulverize and cross 200 mesh sieves to obtain alkaline white clay;

[0032] S3. Disperse the alkaline clay in water, heat it to 60°C, then add hexadecyltrimethylammonium bromide dropwise to the alkaline clay dispersion under stirring, and then add chitosan, wherein Alkaline clay, the mass ratio of cetyltrimethylammonium brom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com