Short branched chain oil absorbent resin and preparation method thereof

A technology of oil-absorbing resin and short branched chain, which is applied in the field of short-chain branched oil-absorbing resin and its preparation, which can solve the problems of difficult stretching of molecular chain segments, lower oil absorption rate of resin, and damage to material flexibility, etc., to achieve high oil retention rate, Improved thermal stability and good oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

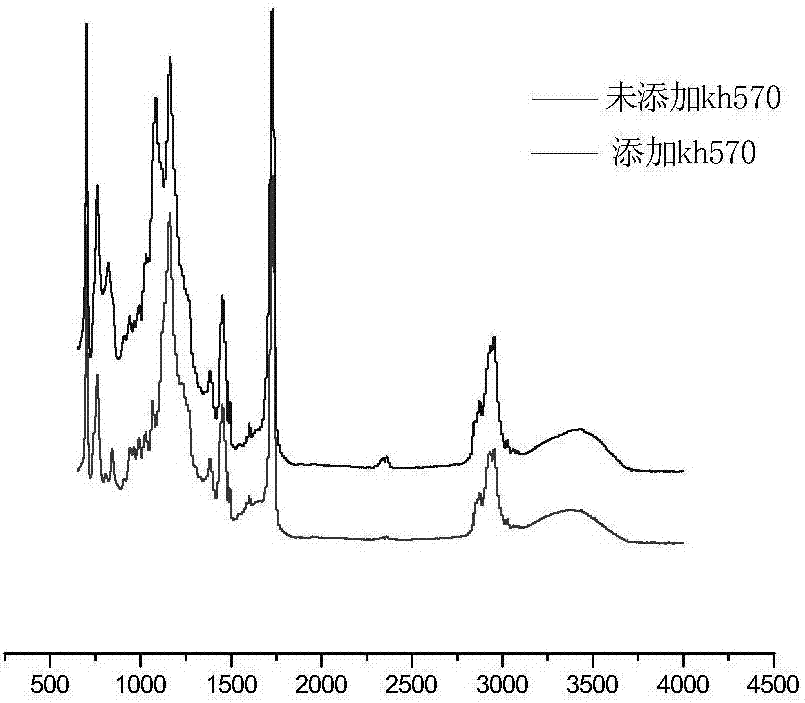

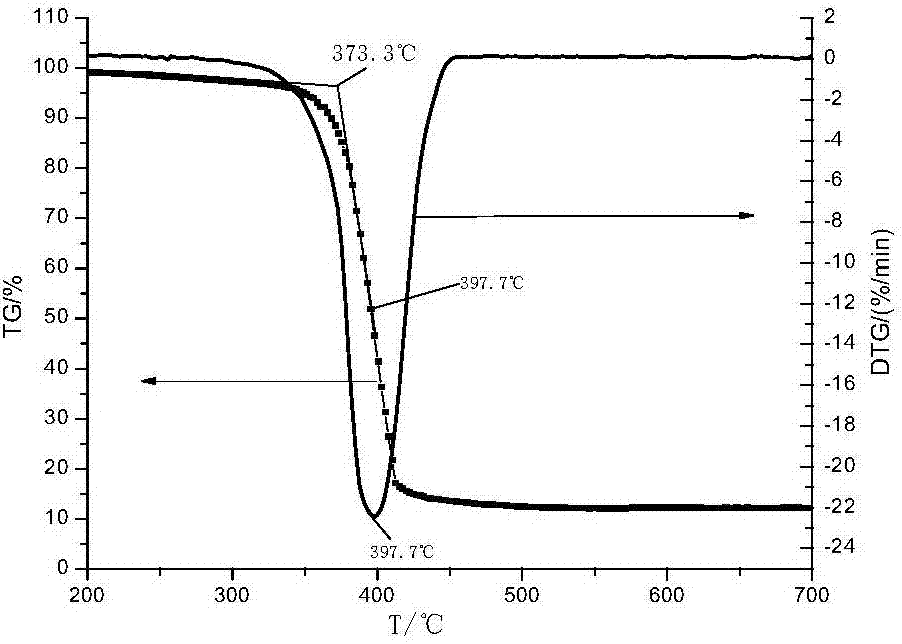

[0019] Example 1), calculated in parts by weight, the resin consists of 5-10 parts of methyl methacrylate, 15-20 parts of butyl acrylate, 2-5 parts of styrene, 0.1-0.3 parts of benzoyl peroxide, poly It is prepared by suspension polymerization of 0.1-0.5 parts of vinyl alcohol and 0.1-0.5 parts of divinylbenzene. The resin has not been polymerized by continuous dropwise addition of KH570, and its decomposition rate is relatively fast and its decomposition temperature is low, such as figure 2 shown.

Embodiment 2)

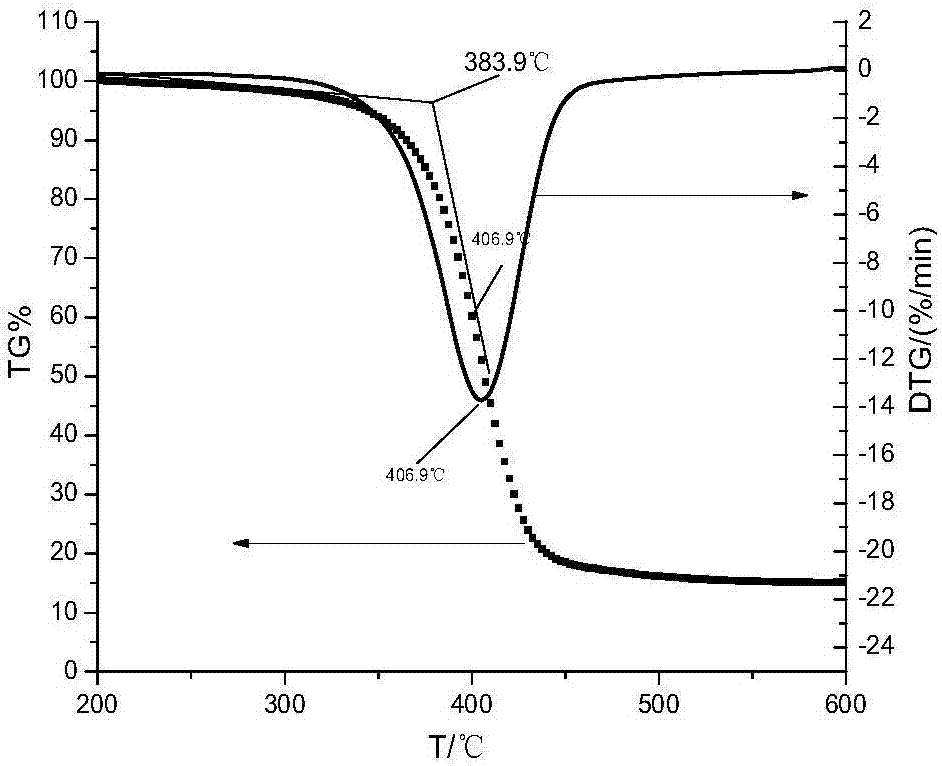

[0020] Example 2), calculated in parts by weight, the resin consists of 5-10 parts of methyl methacrylate, 15-20 parts of butyl acrylate, 2-5 parts of styrene, 0.1-0.3 parts of benzoyl peroxide, poly It is made by suspension polymerization of 0.1~0.5 parts of vinyl alcohol, 0.1~0.5 parts of divinylbenzene, and 1~5 parts of coupling agent KH570, and the coupling agent KH570 is added during the reaction process by continuous dropwise addition. Its decomposition rate is low and its decomposition temperature is high, such as image 3 As shown, the oil absorption rate of the resin does not change much, and the oil retention rate of the oil product is enhanced.

[0021] The oil absorption rate of the resin polymerized by the temperature-programmed process and the continuous dripping process described in the present invention has little change, the smaller the k value of the slow-release equation, the higher the oil retention rate, the higher the thermal decomposition temperature, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com