Shield pump body and processing method thereof

A processing method and technology of canned pumps, applied in the field of canned pumps, can solve the problems of complex production process, low practicability, high production cost, etc., and achieve the effect of simple material formula, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A pump body of a canned pump, the pump body is made by mixing the following components by weight: 57%-62% of nylon six; 32%-35% of glass fiber; 5%-7% of compatibilizer; Agent 0.3%-0.4%; filler: 5%-10%; flame retardant 15%-20%;

[0032] The diameter of the glass fiber is between 21-35μm, and the length is between 0.1-5mm, and the compatibilizer is POE-g-MAH (ST-2) or EPDM-g-MAH (ST-18) or PE- g-MAH (ST-6); wherein the antioxidant is antioxidant 618 or antioxidant 6101 or antioxidant 601; wherein the filler adopts inert materials such as active calcium carbonate or talcum powder or wollastonite or mica; wherein The flame retardant uses a halogen-containing flame retardant or a halogen-free flame retardant. In order to meet environmental protection requirements, the present invention uses a halogen-free flame retardant, such as a white powdery phosphine-nitrogen flame retardant.

[0033] As a preferred solution, a pump body of a canned pump, the pump body is made by mixin...

Embodiment 2

[0040] The manufacturing method and formula components of this embodiment and embodiment 1 are basically the same, the only difference is that the pump body material formula of the canned pump is as follows: nylon six 57%; glass fiber 32%; compatibilizer 5%; antioxidant 0.3 %; filler 5%; flame retardant 15%, wherein the compatibilizer is EPDM-g-MAH (ST-18);

Embodiment 3

[0042] The manufacturing method and formula components of this embodiment and Example 1 are basically the same, the only difference is that the pump body material formula of the canned pump is as follows: nylon six 62%; glass fiber 35%; compatibilizer 6%; antioxidant 0.4 %; filler 8%; flame retardant 18%, wherein the compatibilizer is PE-g-MAH (ST-6).

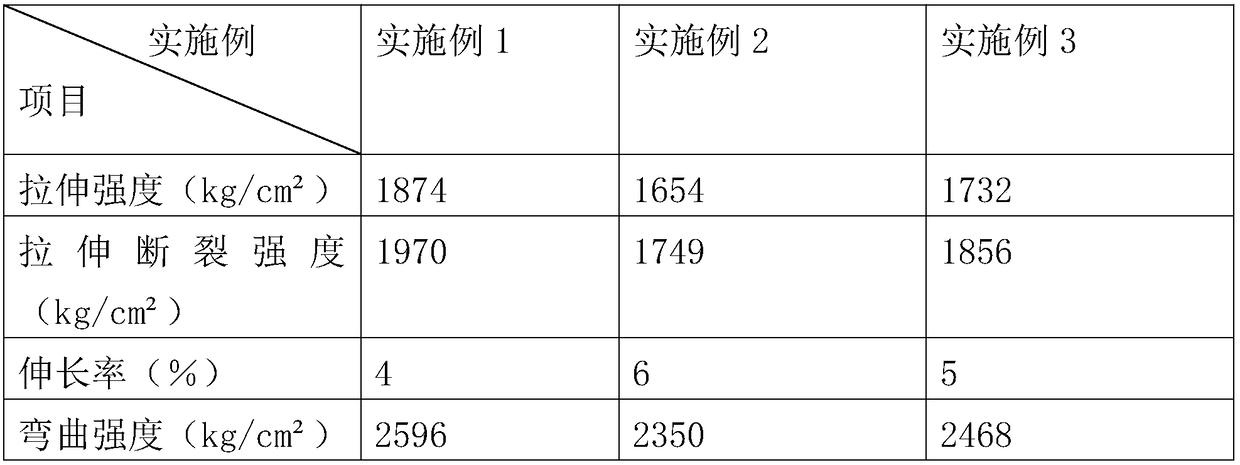

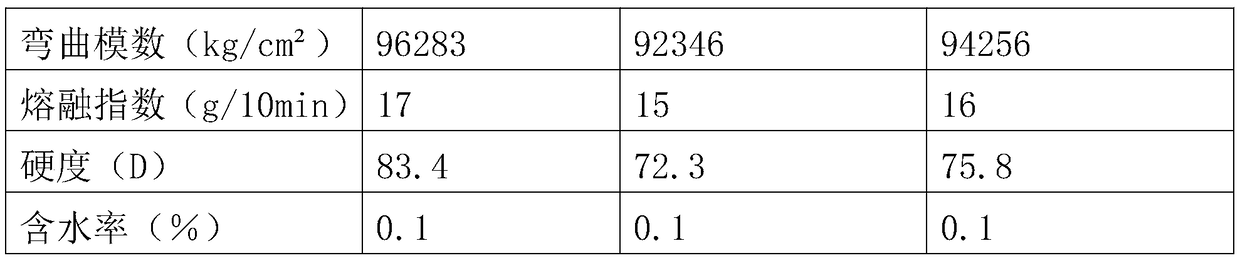

[0043] The performance comparison of the foregoing embodiments is as follows:

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com