Preparation method of plastic with antibacterial function

A plastic and functional technology, which is applied in the field of plastic preparation with antibacterial function, can solve the problems of inconspicuous germ effect and poor antibacterial effect, and achieve the effect of improved antibacterial property, strong impact strength and improved antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

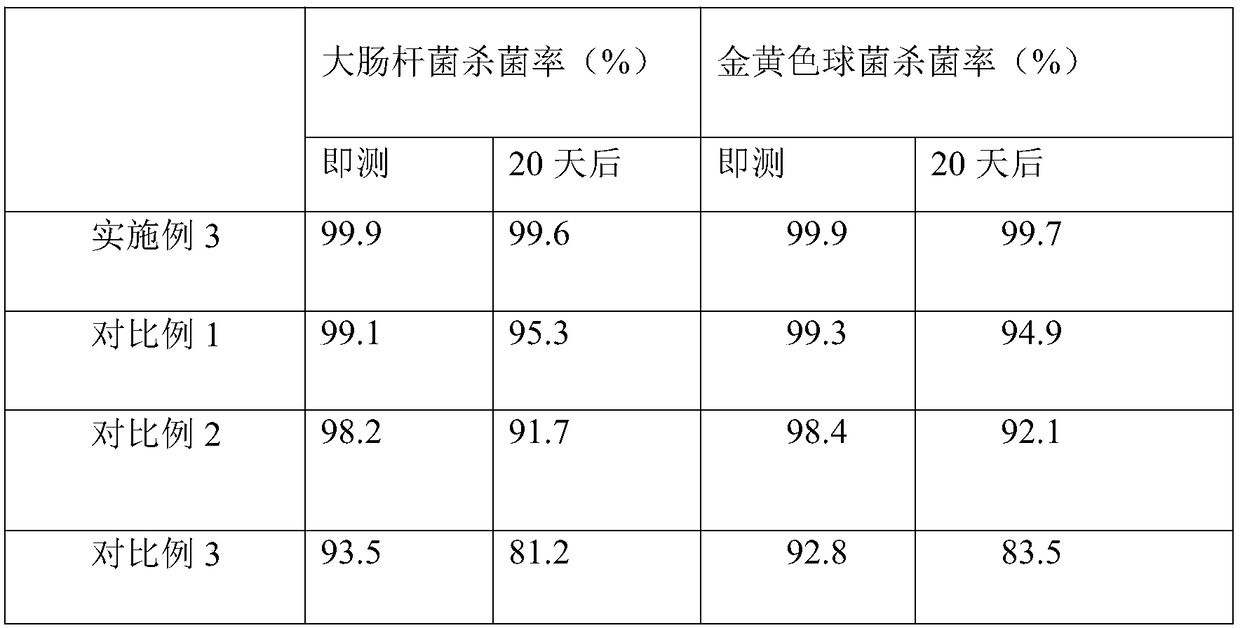

Examples

Embodiment 1

[0027] A kind of plastic preparation method with antibacterial function of the present embodiment, comprises the following steps:

[0028] Step 1: Mix polypropylene resin, modified polyester fiber, and water hyacinth fiber composite polycarbonate, and add them to the reaction kettle. The reaction temperature is 145°C, the stirring speed is 115r / min, and the stirring time is 15min. Then Then add expanded chlorite powder, continue to stir for 35 minutes, then add epoxy silane coupling agent KH-560 and tert-butylhydroquinone in turn, increase the stirring speed to 155r / min, and stir for 35 minutes to obtain mixture A;

[0029] In step 2, the mixture A, tetra-n-butyl titanate and polyvinyl alcohol obtained in step 1 are sent to a twin-screw extruder for extrusion, the extrusion temperature is 155°C, and extrusion cooling is formed to obtain the present invention. Antimicrobial plastic.

[0030] The preparation method of the modified polyester fiber of the present embodiment is: ...

Embodiment 2

[0039] A kind of plastic preparation method with antibacterial function of the present embodiment, comprises the following steps:

[0040] Step 1: Mix polypropylene resin, modified polyester fiber, and water hyacinth fiber composite polycarbonate, and add them to the reaction kettle. The reaction temperature is 155°C, the stirring speed is 125r / min, and the stirring time is 25min. Then Then add expanded chlorite powder, continue stirring for 45 minutes, then add epoxy silane coupling agent KH-560 and tert-butylhydroquinone in sequence, increase the stirring speed to 175r / min, and stir for 45 minutes to obtain mixture A;

[0041] Step 2. The mixture A, tetra-n-butyl titanate and polyvinyl alcohol obtained in step 1 are sent to a twin-screw extruder for extrusion. The extrusion temperature is 165°C. Extrusion is cooled and formed to obtain the present invention. Antimicrobial plastic.

[0042]The preparation method of the modified polyester fiber of the present embodiment is: ...

Embodiment 3

[0051] A kind of plastic preparation method with antibacterial function of the present embodiment, comprises the following steps:

[0052] Step 1: Mix polypropylene resin, modified polyester fiber, and water hyacinth fiber composite polycarbonate, and add them to the reaction kettle. The reaction temperature is 150°C, the stirring speed is 120r / min, and the stirring time is 20min. Then Then add expanded chlorite powder, continue stirring for 40 minutes, then add epoxy silane coupling agent KH-560 and tert-butylhydroquinone in sequence, increase the stirring speed to 160r / min, and stir for 40 minutes to obtain mixture A;

[0053] Step 2, the mixture A, tetra-n-butyl titanate, and polyvinyl alcohol obtained in step 1 are sent to a twin-screw extruder for extrusion, the extrusion temperature is 160 ° C, extrusion cooling is formed, and the present invention has Antimicrobial plastic.

[0054] The preparation method of the modified polyester fiber of the present embodiment is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com