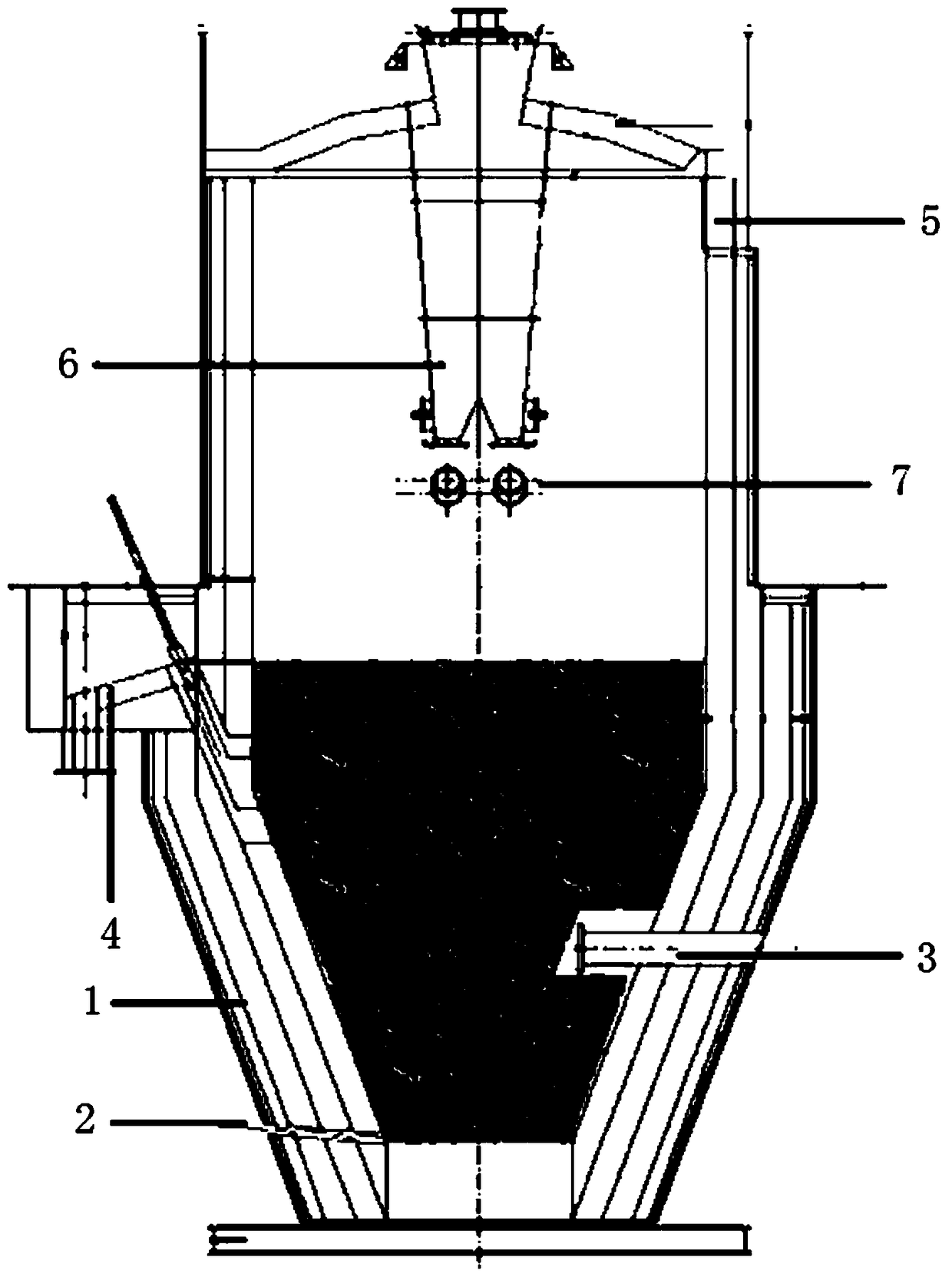

Large-capacity molten salt chlorinating device for treating high-calcium magnesium titanium slag and production method

A molten salt chlorination, high calcium and magnesium technology, applied in titanium tetrachloride, titanium halide and other directions, can solve the problems of low chlorination efficiency, low production capacity of high calcium magnesium titanium slag, etc. The efficiency of chlorination reaction and the effect of increasing the diameter of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

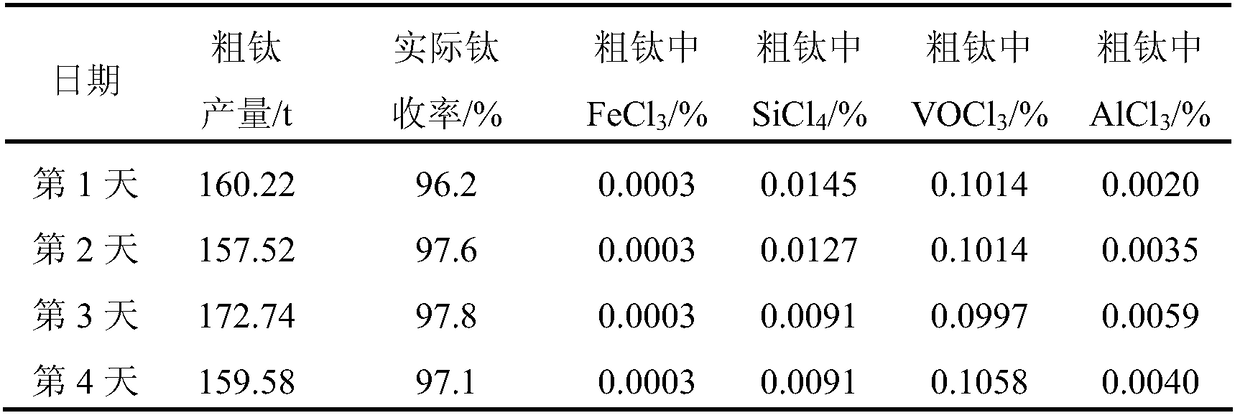

Embodiment 1

[0032] Adopting the large-capacity molten salt chlorination device involved in the present invention, the solid material is transported into the molten salt through the furnace top silo and the feeding screw, and chlorine gas is input through the bottom gas nozzle, wherein the solid titanium slag material is composed of: TiO 2 -73.88%, FeO-8.59%, SiO 2 -4.16%, MnO-1.30%, V 2 o 5-0.30%, MgO-5.34%, CaO-1.71%; C content in petroleum coke is 98%, volatile matter is 0.56%, ash content is 0.5%; 2 -1.66%, N2-7.87%; NaCl content is 98.5% in the sodium chloride salt, and under test condition, titanium slag: petroleum coke: sodium chloride: the ratio of chlorine is 0.643:0.104:0.157:1, and the reaction process of feeding control The temperature is 750°C ~ 780°C. During the process, the temperature of the molten salt is stably controlled by the titanium tetrachloride slurry, and the high temperature flue gas is cooled by the titanium tetrachloride slurry, and the temperature of the mix...

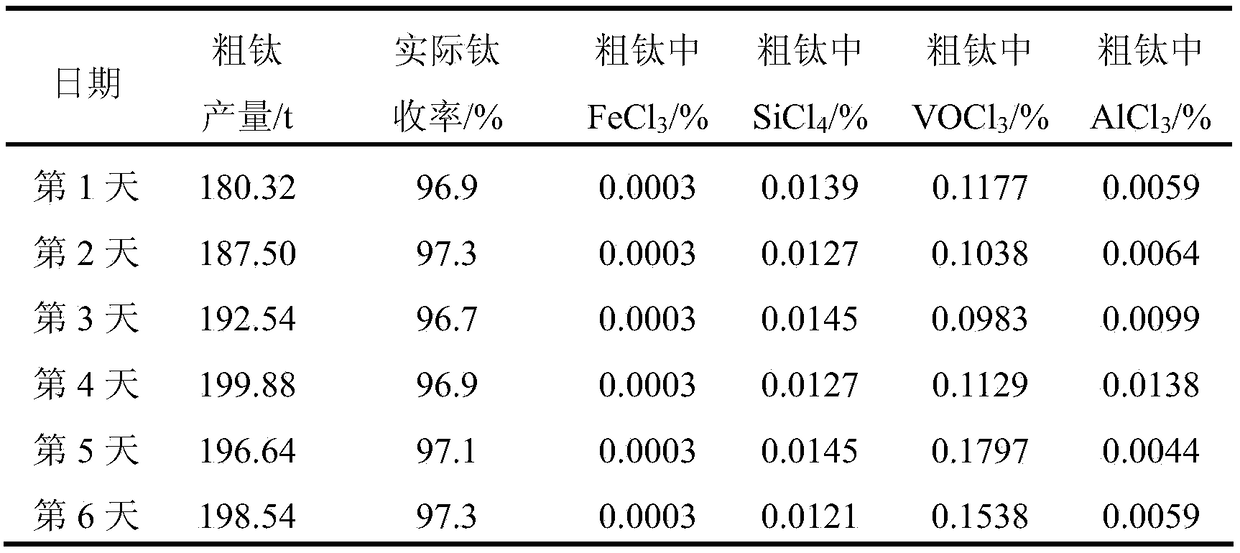

Embodiment 2

[0037] Adopt the large-capacity molten salt chlorination device involved in the present invention, wherein the solid titanium slag material is composed of: TiO 2 -78.3%, FeO-6.59%, SiO 2 -3.17%, MnO-1.10%, V 2 o 5 -0.21%, MgO-3.34%, CaO-1.78%; the C content in petroleum coke is 98%, the volatile matter is 0.56%, and the ash content is 0.5%; the chlorine gas in the furnace is composed of Cl 2 -85%~88%, CO 2 -1.7%, N 2 -7.9%; NaCl content is 98.5% in the sodium chloride salt, under test condition, titanium slag: petroleum coke: sodium chloride: chlorine=1:0.15:0.263:1.55, pass furnace top silo and feeding screw in the chlorination process The solid material is transported into the molten salt, and chlorine gas is input through the gas nozzle at the bottom. The temperature of the reaction process is controlled by feeding to 760°C to 770°C, and the temperature of the mixed flue gas is controlled to be 360°C to 430°C. Further, through the follow-up supporting dust collection sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com