A marine vibration damping paddle shaft

A propeller shaft and vibrating propeller technology, applied in the field of vibration reduction and noise reduction, can solve the problems of reducing the use accuracy, wear of parts, damage to the propeller, etc., and achieve the effect of inhibiting the transmission of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing:

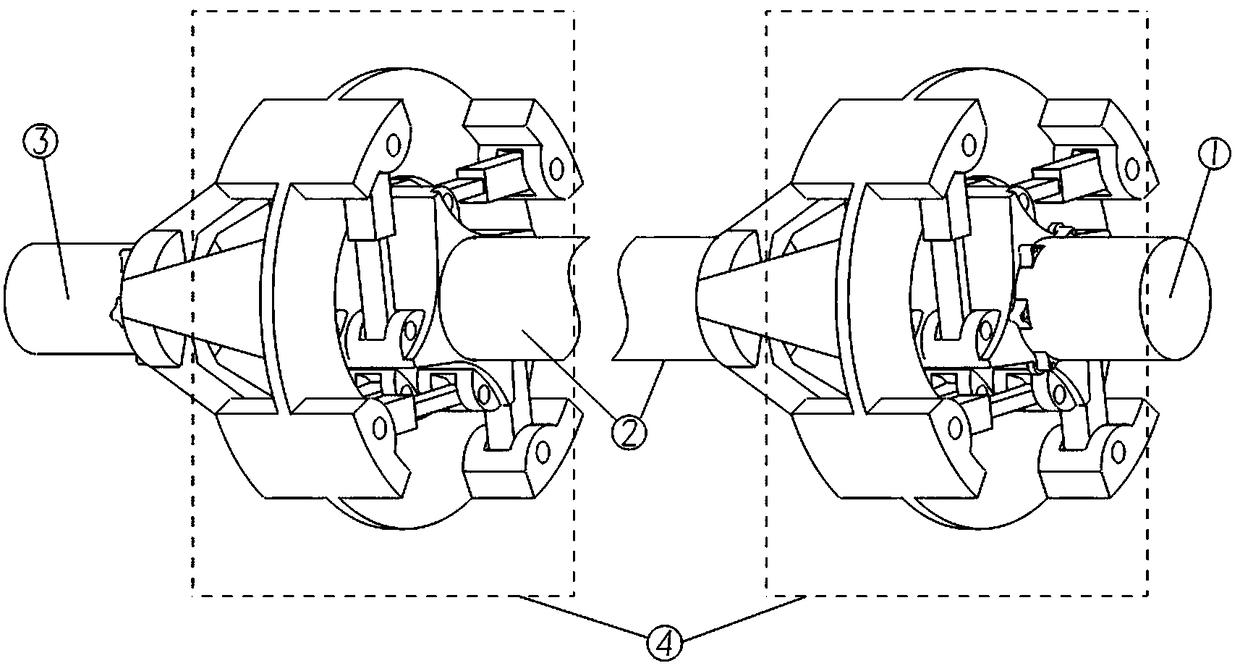

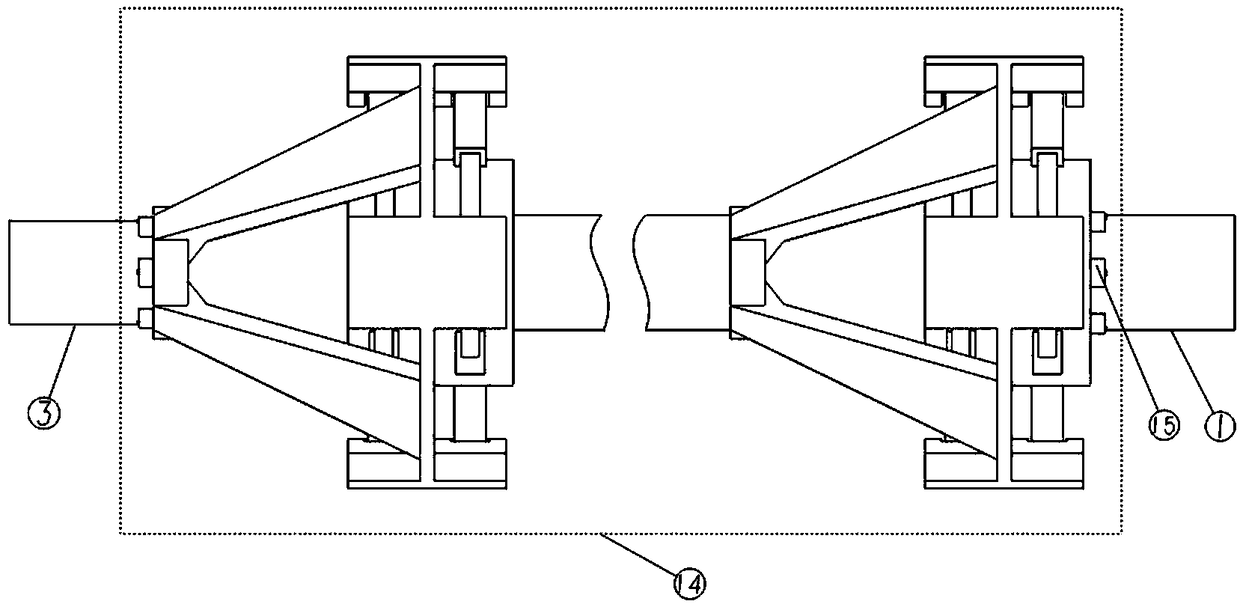

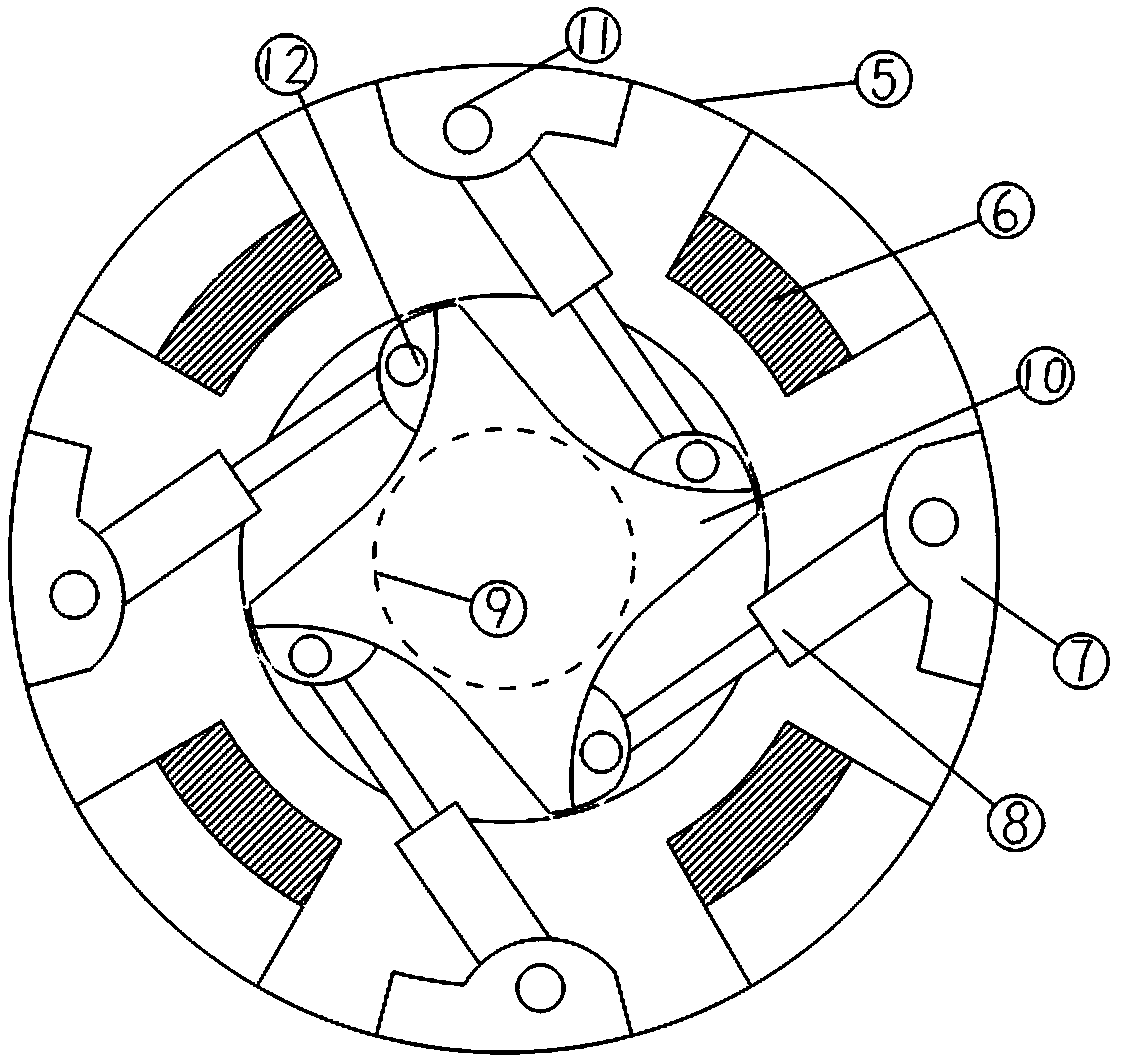

[0027] combine figure 1 , 2 , 3, 4, 5, 6, the working principle of the marine damping propeller shaft is:

[0028] The marine propeller shaft is divided into three sections: the front part of the propeller shaft 1, the middle part of the propeller shaft 2, and the end part of the propeller shaft 3. The length of the middle part of the propeller shaft 2 accounts for the main part of the total length of the propeller shaft. A vibration damping mechanism is connected to one end of the middle section of the paddle shaft, and the other end of the middle section of the paddle shaft is connected to the end section of the paddle shaft through a second vibration damping mechanism, and the front section of the paddle shaft, the middle section of the paddle shaft, the end section of the paddle shaft and the two vibration damping mechanisms rotate simultaneously;

[0029] The stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com