Method and device for treating drilling residues of printed circuit board

A technology for printed circuit boards and processing devices, which is applied in the field of processing of drilling residues on printed circuit boards, can solve problems such as poor product reliability, scrapping, and poor hole plugging, and achieves improved success rate, high cleaning efficiency, and avoidance of secondary problems. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

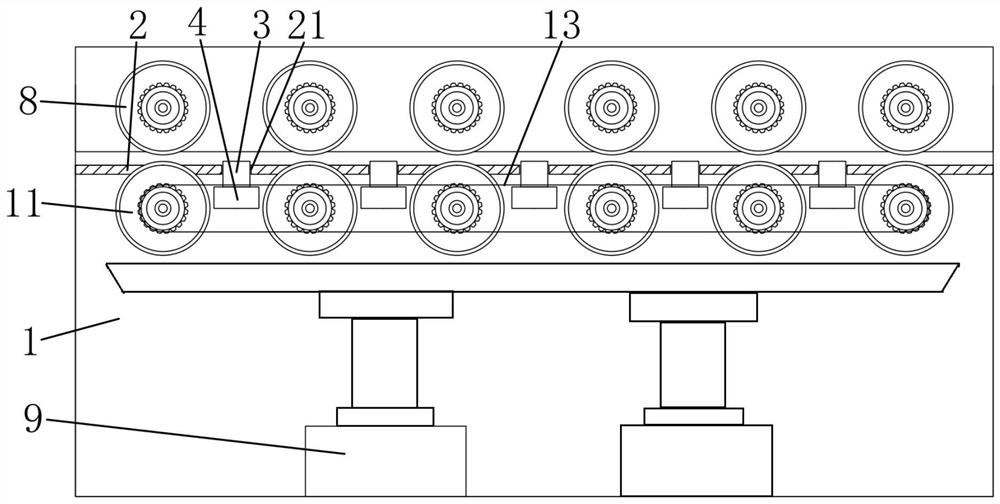

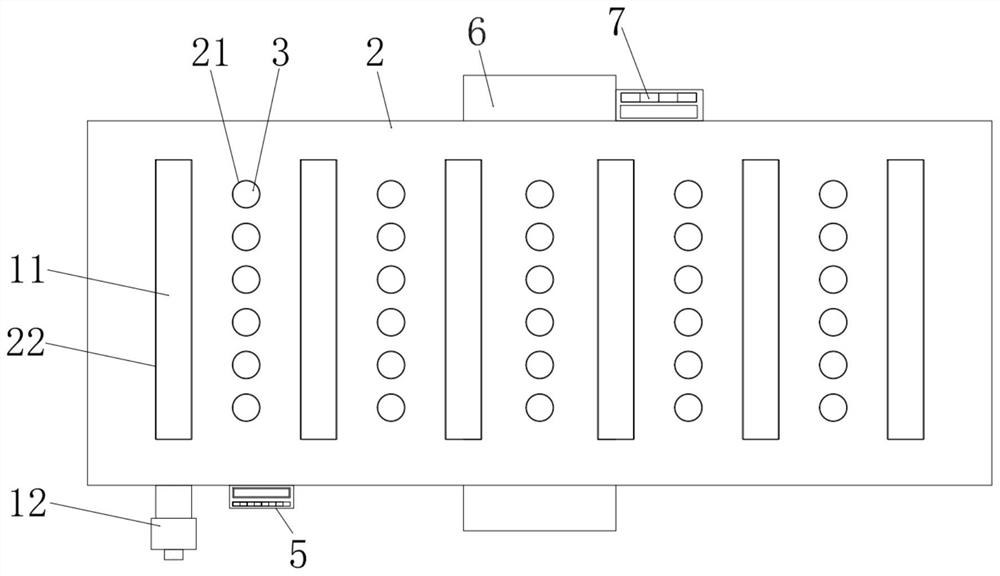

[0027] The specific embodiment of the present invention is as Figure 1 to Figure 2 As shown, a method for processing the drilling residue of printed circuit boards, before the printed circuit boards are washed with water, the printed circuit boards are moved along the conveying path, and the drilled holes to be cleaned are vibrated.

[0028] The conveying path drives the printed circuit board to advance through the rollers, and the vibration cleaning includes knocking on the ejector pin and operation of the vibrator, and the knocking on the ejector pin and the operation of the vibrator are performed simultaneously. The printed circuit board is driven forward by the row roller 11 on the conveying path, which can make the cleaning efficiency of the printed circuit board higher. When the printed circuit board reaches the conveying path, the row roller 11 stops running for about 1 to 3 seconds, and the driving mechanism 4 Drive the ejector rod 3 to move up and down to knock the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com