Air-conditioning unit

A technology for air conditioning devices and heat exchangers, which is applied in the directions of heat exchange equipment safety devices, space heating and ventilation, space heating and ventilation details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

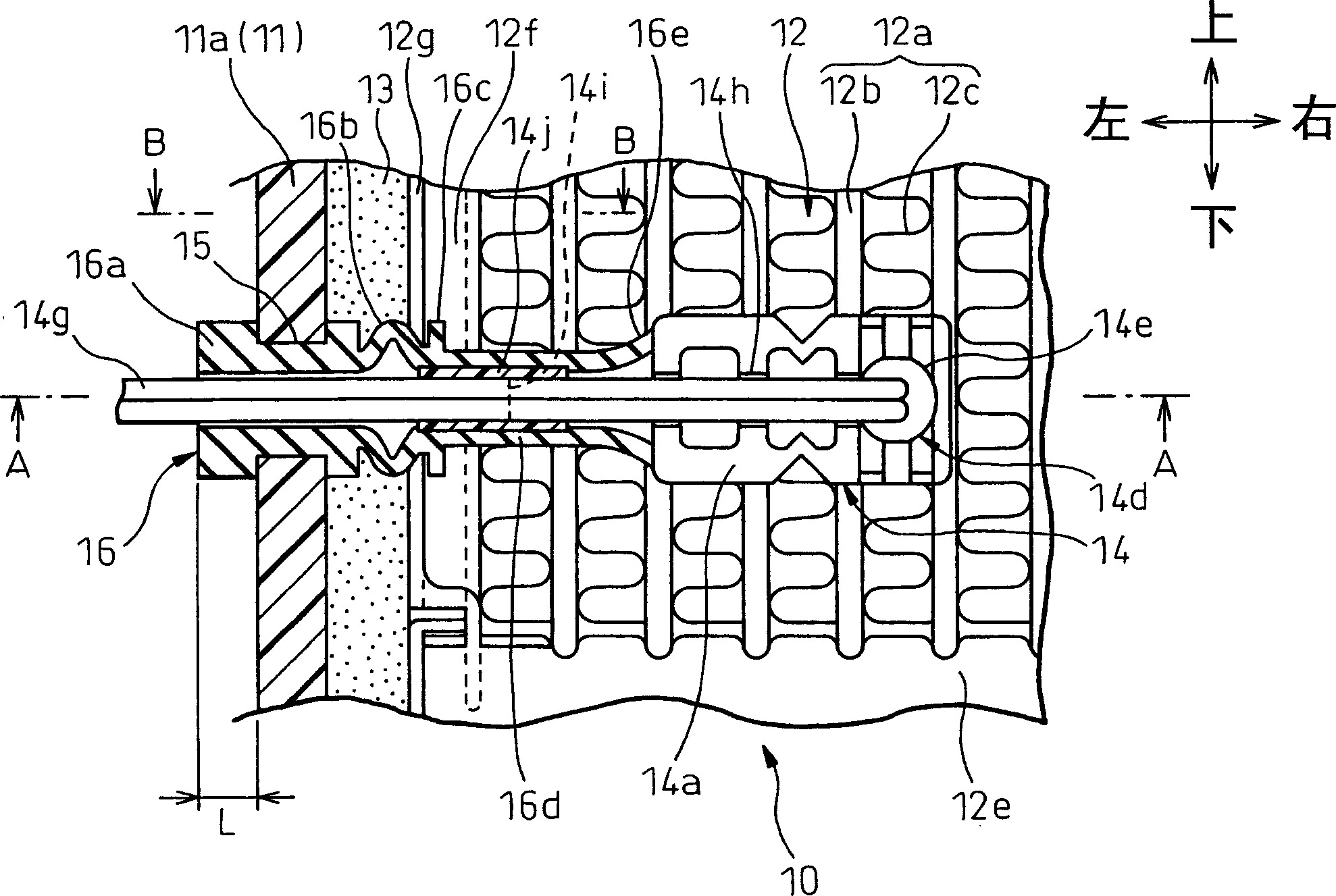

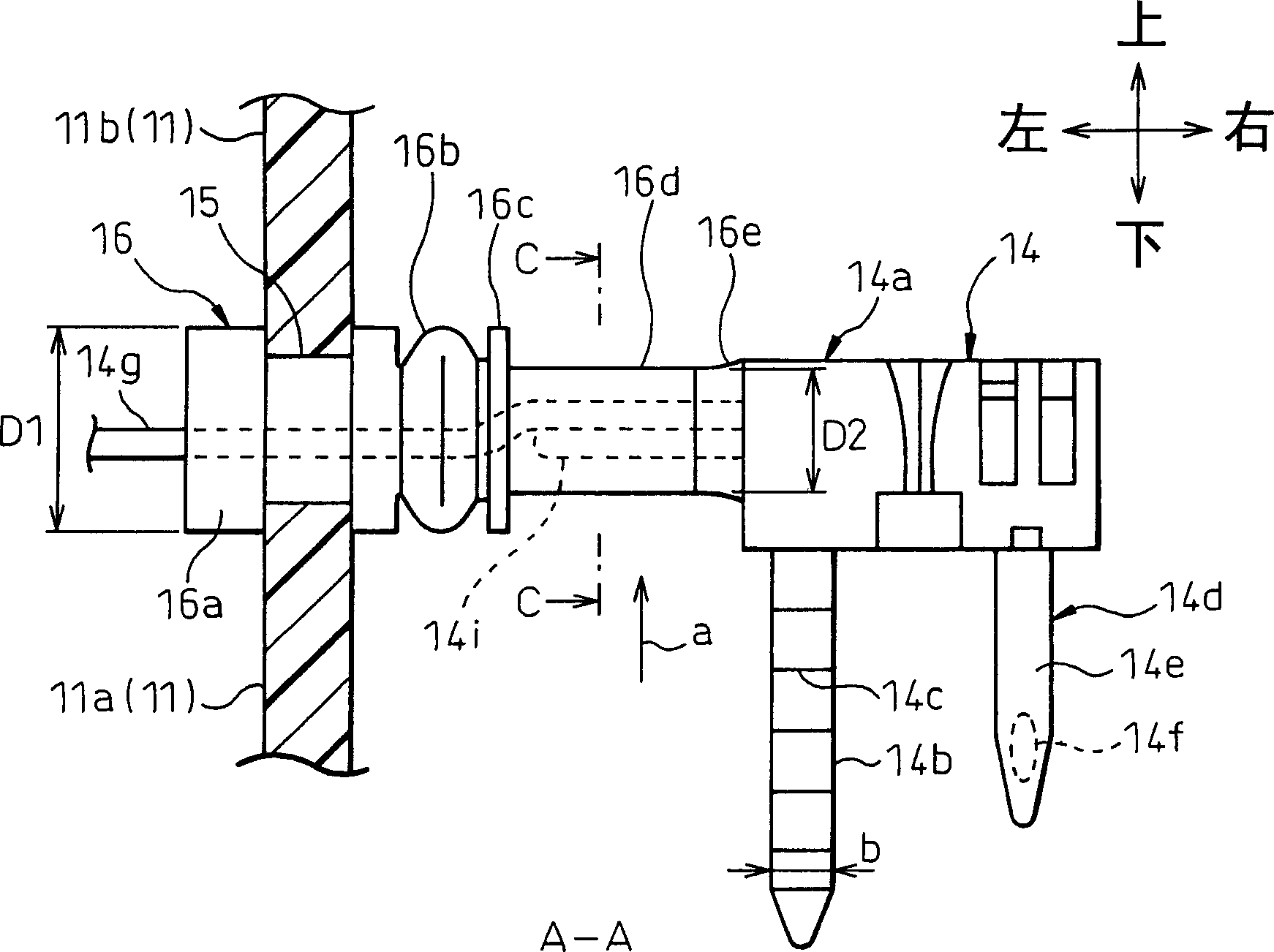

[0061] Embodiments of the present invention are described with reference to the drawings. figure 1 is a sectional view showing the main part of the air conditioner 10 using the structure of the sensor assembly according to the present invention. Figure 2A is shown along figure 1 A cross-sectional view of the middle line A-A. Figure 2B is showing Figure 2A Front view of sleeve bellows shown. image 3 is shown along Figure 2A Sectional view of the middle line C-C. figure 1 , 2A The vertical, horizontal, and longitudinal directions in correspond to the vertical, horizontal, and longitudinal directions of the vehicle.

[0062] The casing 11 of the air conditioner 10 has two functions, on the one hand, it is to form an air channel for the conditioned air; door (not shown). The case 11 is formed of resin, and is divided into a plurality of division cases 11a, 11b in order to facilitate release of the resin molding die and assembly of accommodated devices. The mating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com