Preparation method and application of carbon-coated nano copper-zinc-aluminum catalyst

A catalyst and nano-copper technology, applied in the field of catalysis, can solve the problems of loss of active components, low mechanical strength, long processing time, etc., to reduce the side reactions of esterification and etherification, improve selectivity and stability, and reduce catalyst activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

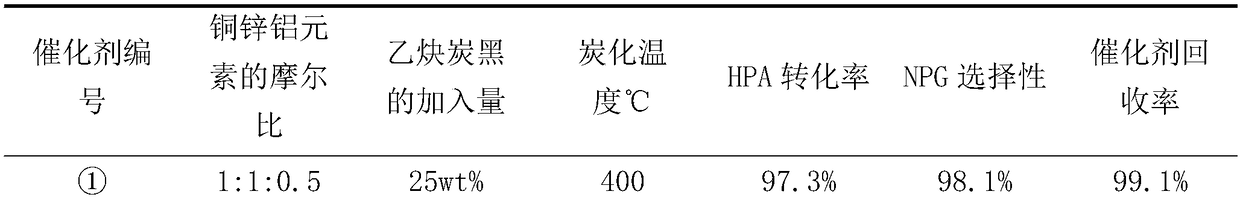

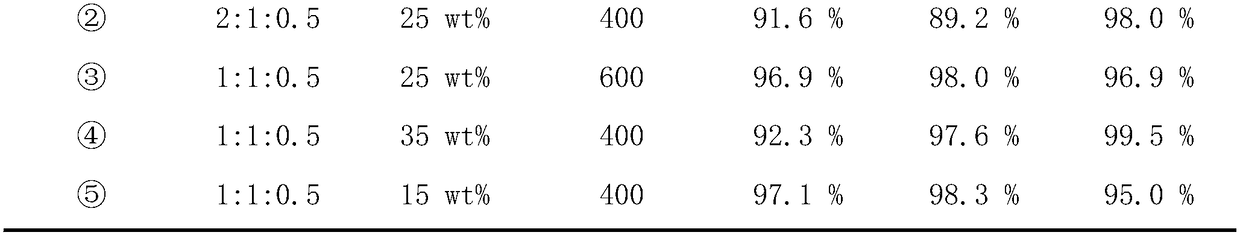

Embodiment 1

[0042] Catalyst preparation:

[0043] (1) Mix copper nitrate, zinc nitrate, and aluminum nitrate in a molar ratio of 1:1:0.5, then add acetylene carbon black by 25wt% of the total mass of the metal compound, and then ethanol by mass ratio: (carbon-based material+metal compound )=5:1 adding ethanol, stirring and mixing for 24h to obtain a slurry;

[0044] (2) heating the slurry obtained in step (1) to 80° C. and stirring for 1 h, evaporating ethanol until the mixture becomes a paste, and then drying at 70° C. for 24 h to obtain a carbon-coated nano-copper-zinc-aluminum catalyst precursor;

[0045] (3) Carbonize 40g of the precursor obtained in step (2) under the protection of nitrogen at a rate of 50ml / min, raise the temperature to 400°C at a rate of 5°C / min, and keep the temperature constant for 4 hours, and then take it out after the temperature naturally drops below 80°C. Obtain carbonized compound;

[0046] (4) Mix the carbonized compound in step (3) with concentrated hyd...

Embodiment 2

[0052] Catalyst preparation:

[0053] (1) Mix copper nitrate, zinc nitrate, and aluminum nitrate in a molar ratio of 2:1:0.5, then add 25wt% of the total mass of the metal compound and add acetylene carbon black, then ethanol by mass ratio: (carbon-based material+metal compound )=5:1 adding ethanol, stirring and mixing for 24h to obtain a slurry;

[0054] (2) Heat the slurry obtained in step (1) to 80° C. and stir for 1 h, evaporate the ethanol in step (1) until the mixture becomes a paste, and dry at 70° C. for 24 h to obtain carbon-coated nano-copper zinc-aluminum catalyst. Precursor;

[0055] (3) Carbonize 40g of the mixture in step (2) under the protection of nitrogen at a rate of 50ml / min, raise the temperature to 400°C at a rate of 5°C / min, and keep the temperature constant for 4h, then take it out after the temperature naturally drops below 80°C to obtain carbonization compound;

[0056] (4) Mix the carbonized compound in step (3) with 37wt% concentrated hydrochloric...

Embodiment 3

[0061] Catalyst preparation:

[0062] (1) Mix copper nitrate, zinc nitrate, and aluminum nitrate in a molar ratio of 1:1:0.5, then add 25wt% of the total mass of the metal compound and add acetylene carbon black, then ethanol by mass ratio: (carbon-based material+metal compound )=5:1 Add ethanol, stir and mix for 24h, then place in 80°C water bath to obtain slurry;

[0063] (2) Heat the slurry obtained in step (1) to 80° C. and stir for 1 h, evaporate the ethanol in step (1) until the mixture becomes a paste, and dry at 70° C. for 24 h to obtain carbon-coated nano-copper zinc-aluminum catalyst. Precursor;

[0064] (3) Carbonize 40g of the precursor in step (2) under the protection of nitrogen at a rate of 50ml / min, raise the temperature to 600°C at 5°C / min, and keep the temperature constant for 4h, and then take it out after the temperature naturally drops below 80°C to obtain Carbonized compound;

[0065] (4) Mix the carbonized compound in step (3) with 37% concentrated hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com