Preparation method of hydrophilic coating on guide wire surface of medical catheter, and product of preparation method

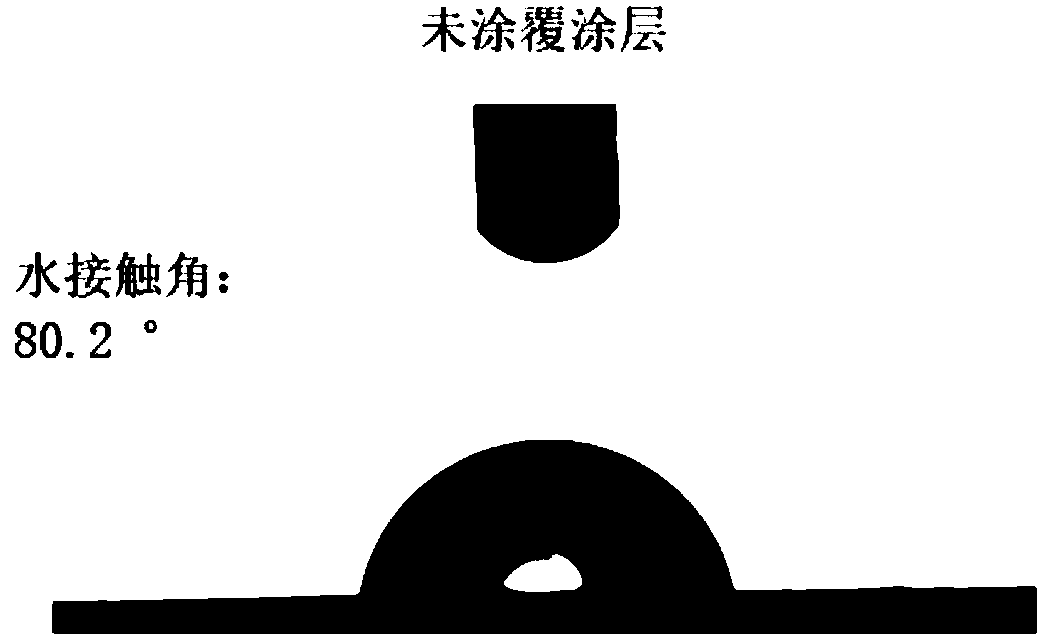

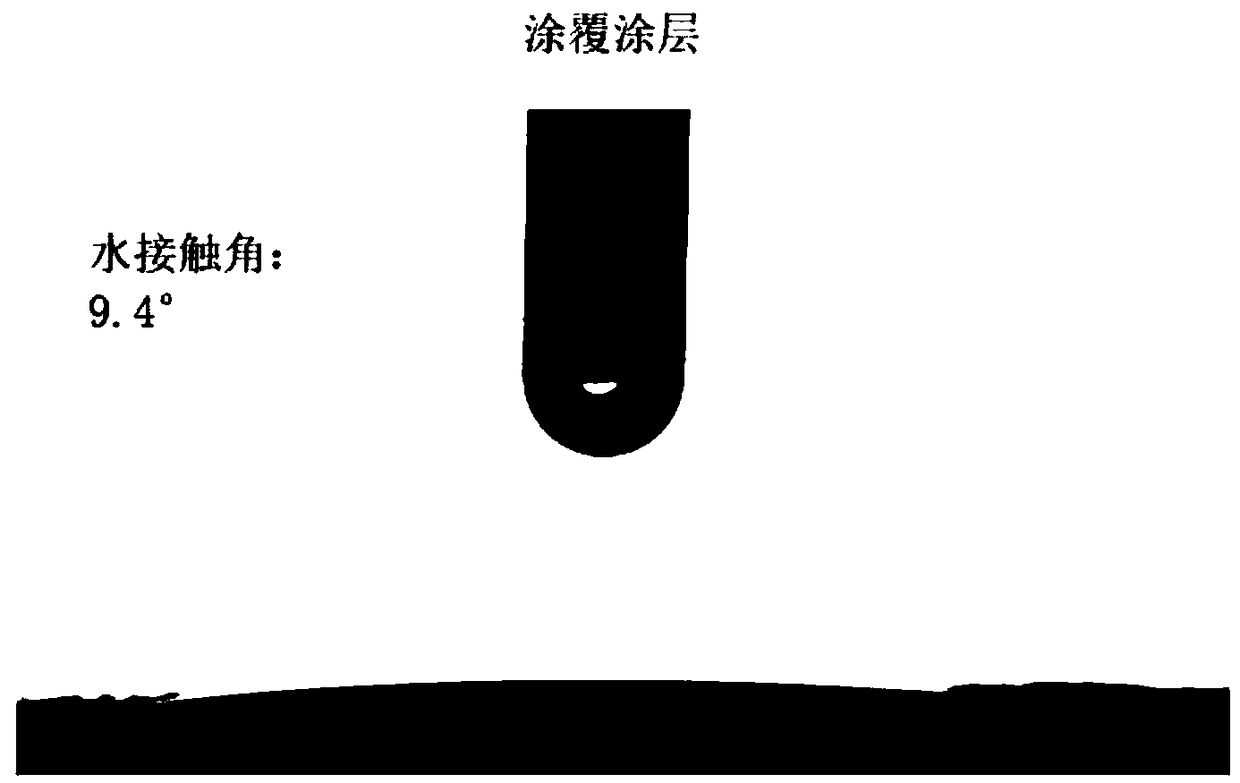

A medical catheter and hydrophilic coating technology, applied in catheters, coatings, pharmaceutical formulations, etc., can solve the problems of lack of lasting lubricity, easy residue of organic solvents, complicated steps, etc., to improve the surface performance of catheters, hydrophilic Outstanding lubricity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh 50g of aqueous polyurethane dispersion, dissolve 5g of polyvinylpyrrolidone in 100g of deionized water, add the polyurethane dispersion into the polyvinylpyrrolidone solution, and stir at 30°C for one hour to obtain a uniform solution.

[0030] 2) After adding a few drops of ammonia water to adjust the pH value of the solution to 8-9, weigh 1.5 g of siloxane crosslinking agent and add it to the above solution, stir for 15 minutes, and ultrasonicate for 5 minutes to obtain a homogeneous solution.

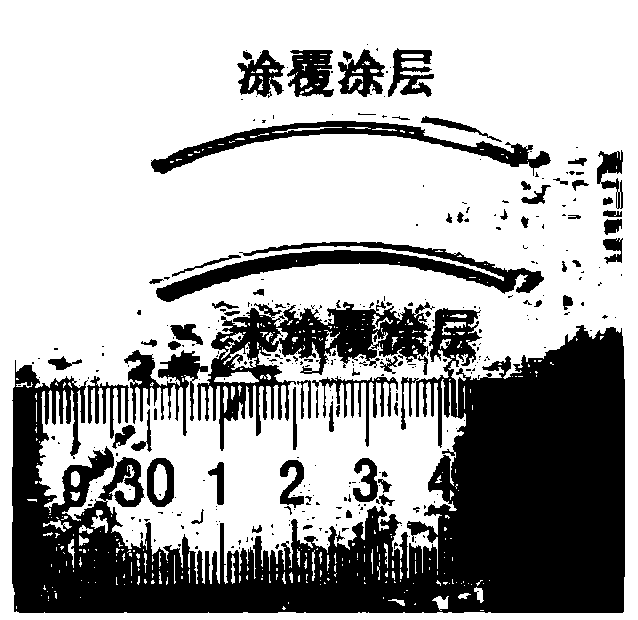

[0031] 3) Dip the medical catheter guide wire into the coating solution, wait for 20 seconds, pull out the catheter guide wire at a uniform speed with a puller, and then put it in a 50°C drying oven to dry for 4 hours to obtain a uniform coating.

Embodiment 2

[0033] 1) Weigh 50 g of water-based acrylic resin dispersion, dissolve 3 g of agarose in 100 g of deionized water, add the acrylic acid dispersion into the agarose solution, and stir at room temperature for three hours to obtain a uniform solution.

[0034] 2) After adding a few drops of ammonia water to adjust the pH value of the solution to 8-9, weigh 1.5 g of polyisocyanate crosslinking agent and add it to the above solution, stir for 25 minutes, and sonicate for 10 minutes to obtain a homogeneous solution.

[0035] 3) Dip the medical catheter guide wire into the coating solution, wait for 15 seconds, pull out the catheter guide wire at a uniform speed with a puller, and then put it in an 80°C drying oven to dry for 2 hours to obtain a uniform coating.

Embodiment 3

[0037] 1) Weigh 50 g of water-based polyurethane dispersion, dissolve 8 g of xanthan gum in 100 g of deionized water, add the polyurethane dispersion into the xanthan gum solution, and stir for three hours at room temperature to obtain a uniform solution.

[0038] 2) After adding a few drops of ammonia water to adjust the pH value of the solution to 8-9, weigh 2 g of carbodiimide crosslinking agent and add it to the above solution, stir for 15 minutes, and sonicate for 10 minutes to obtain a homogeneous solution.

[0039] 3) Dip the medical catheter guide wire into the coating solution, wait for 20 seconds, pull out the catheter guide wire at a uniform speed with a puller, and then put it in a 60°C drying oven to dry for 5 hours to obtain a uniform coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com