An auxiliary structure based on a manufacturing process for improving the robustness of a fuel cell metal polar plate

A metal plate and fuel cell technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of inability to apply the robust manufacturing process of the metal plate, poor rigidity of the positioning hole of the metal plate, and inability to accurately locate. To achieve the effect of suppressing the risk of glue overflow, ensuring the stability of gas circulation, and reducing the span distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

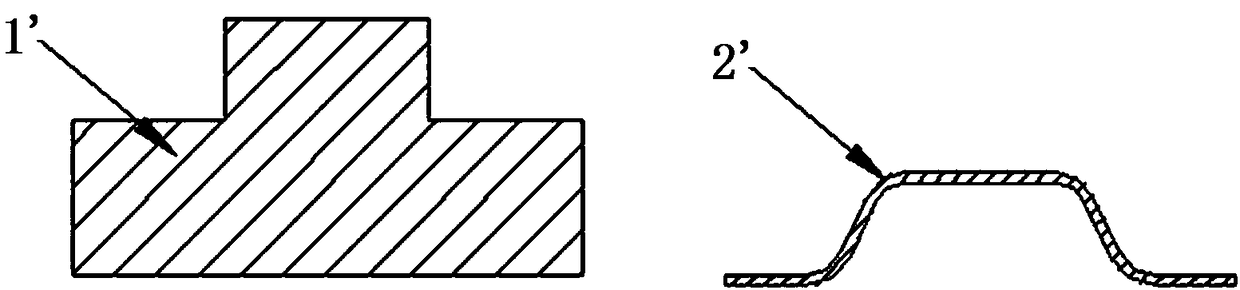

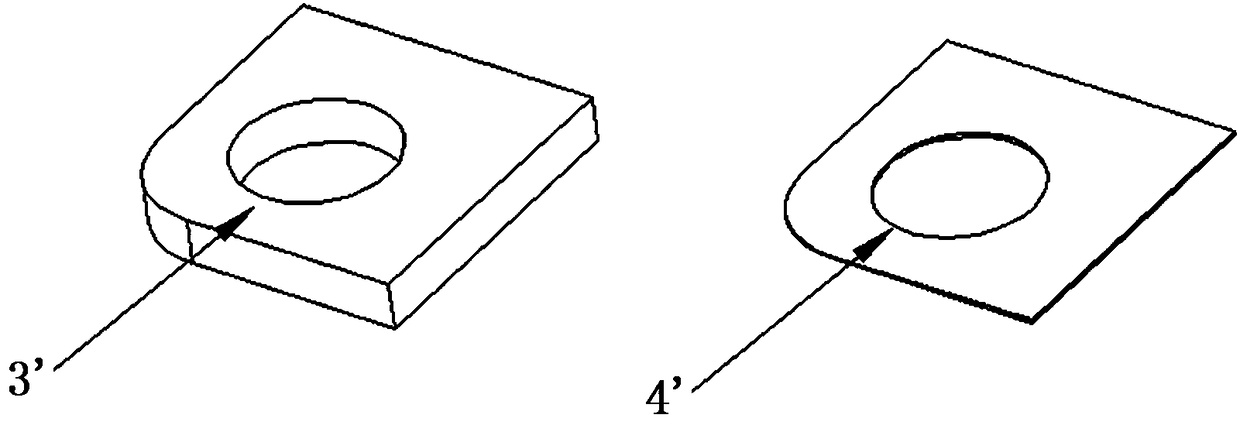

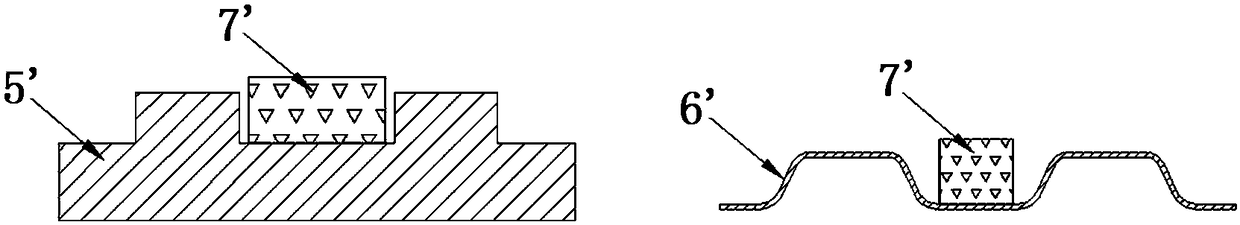

[0025] see Figure 4 , an auxiliary structure based on the process of improving the robustness of the fuel cell metal plate, including a positioning hole reinforcement structure 1 arranged on the metal plate, an MEA depression suppression structure 2, a sealing rubber ring lateral slip suppression structure 3, The sealing feature reinforcement structure 4 and the primer overflow suppression structure 5 .

[0026] The overall shape of the metal pole plate is rectangular, and the four corners of the metal pole plate are respectively provided with pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com