Mold pouring molding wound inductor and preparation method thereof

A wire-wound inductor and infusion molding technology, which is applied in the field of inductors, can solve problems affecting the welding of inductors and PCBs, limited external impact force, damage, etc., to improve the ability to withstand DC superposition Isat, reduce the fullness, The effect of reducing the DC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

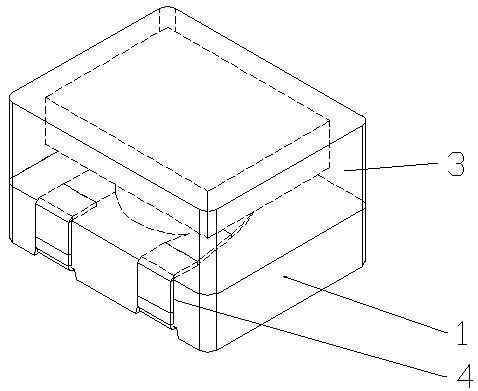

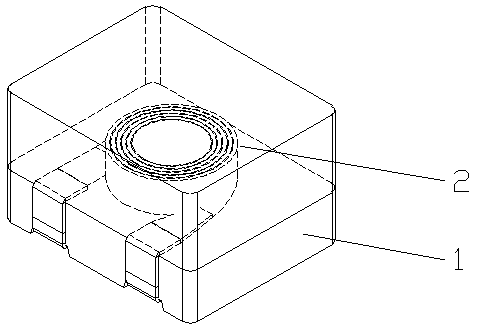

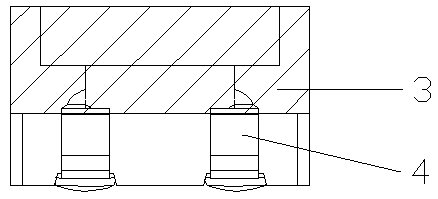

[0018] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 22 , the preparation method of the mold injection molded wire wound inductor described in the present embodiment includes the following steps, prefabricating the soft magnetic core-soft magnetic core outer coating layer treatment-soft magnetic core terminal electrode formation-coil wire roll Winding, spot welding—fixture filling with magnetic glue—glue drying—lower fixture—external inspection—printing—testing, and it’s done. The fixture filling with magnetic glue is to first place the product in the fixture, then pour the magnetic glue, and then Take out the product from the jig, which is as follows: inject the prepared magnetic glue into the hole of the jig with a precision dispensing machine, and then put the solder surface of the inductance device with the enameled wire upsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com