Grading material specific area determining method based on three-dimensional laser scanning and image processing technology

A specific surface area and three-dimensional laser technology, which is applied in the direction of permeability/surface area analysis, suspension and porous material analysis, and the use of optical devices, can solve problems such as complex calculation principles, complex processing techniques, and demanding material sizes to be tested. Achieve the effects of ensuring calculation accuracy, improving modeling efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

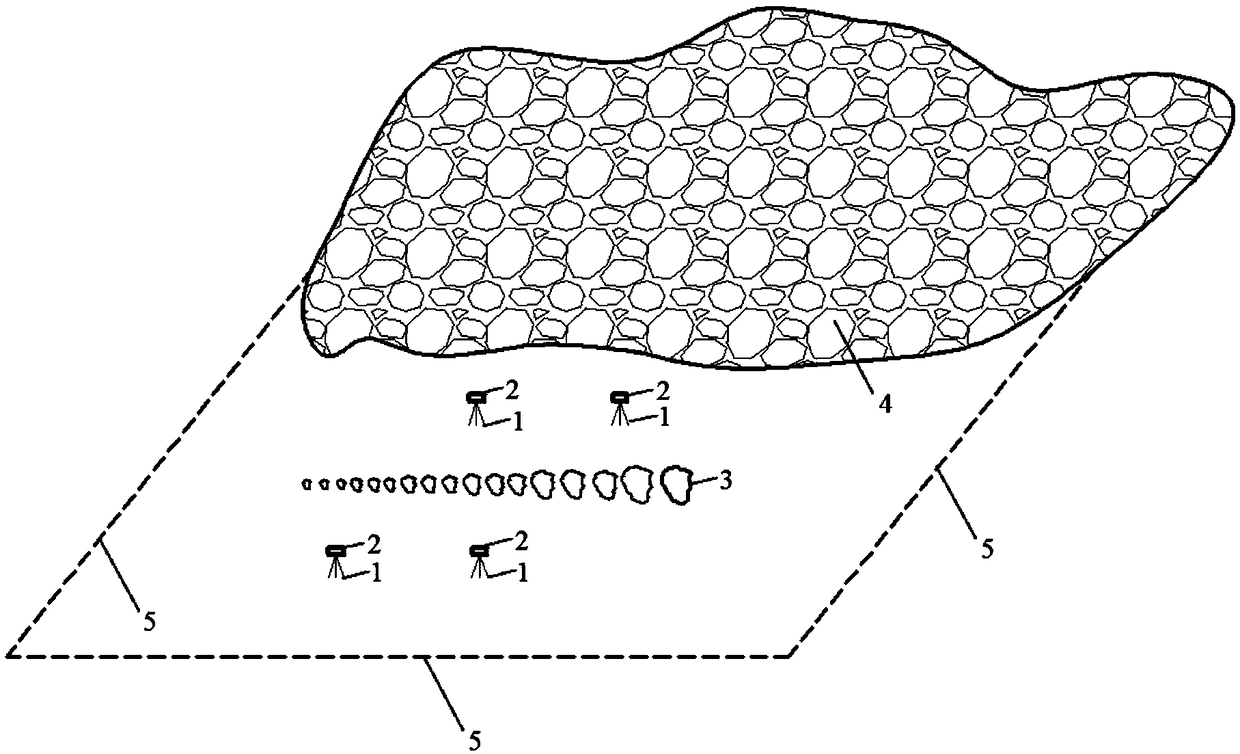

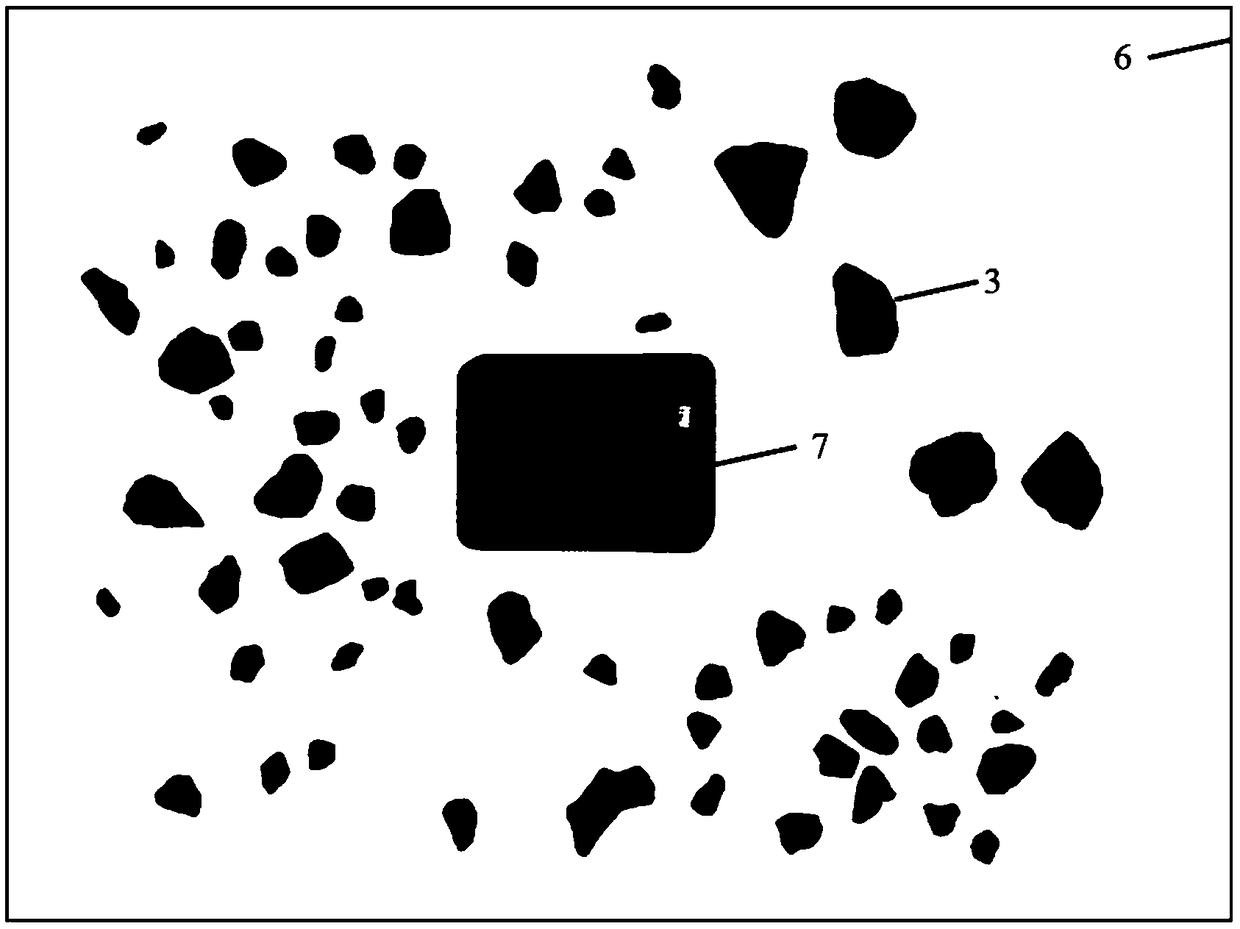

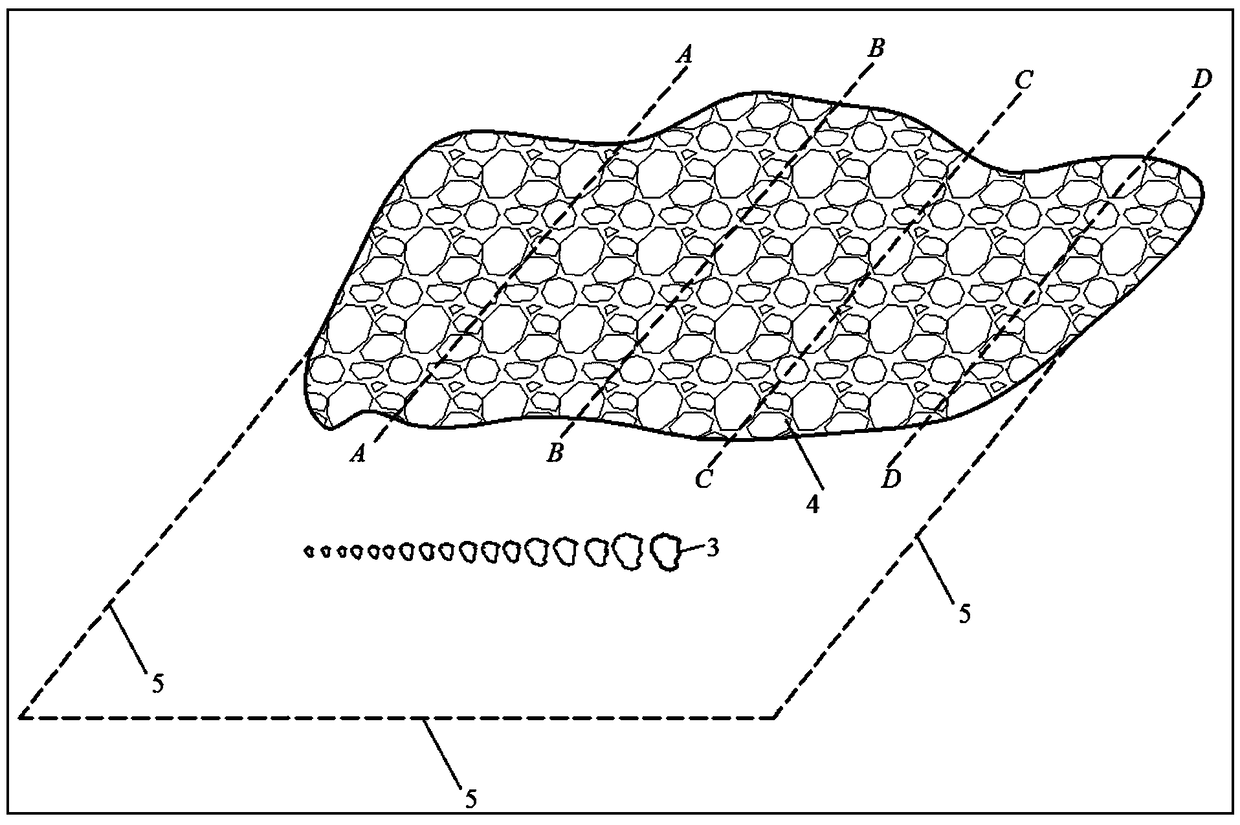

[0054] The present invention will be further introduced below in conjunction with the accompanying drawings and specific examples. Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in a hydropower station sandstone processing system, a single-consumption lower-level batching blasting mining, aggregates with a size greater than 5mm after blasting accounted for 95%, and the maximum aggregate size was 1200-1500mm. A method for determining the specific surface area of graded ingredients based on three-dimensional laser scanning and image processing technology, comprising the following steps:

[0055] (1) Select rock blocks with a size of 50-1500mm in the explosive pile, starting from 50mm, select 3-4 rock blocks at intervals of 50-60mm, and use an excavator or a breaker to arrange the rock blocks in a row according to their size ( Arranging according to size can avoid the problem of small blocks being blocked when arranged in a chaotic manner, and can also improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com