Simultaneous measurement of the levelness of the end surface of the circular pipe at both ends of the rubbing detection device and detection method

A detection device and detection method technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of laborious accuracy and other problems, and achieve the effect of good convenience, good stability and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

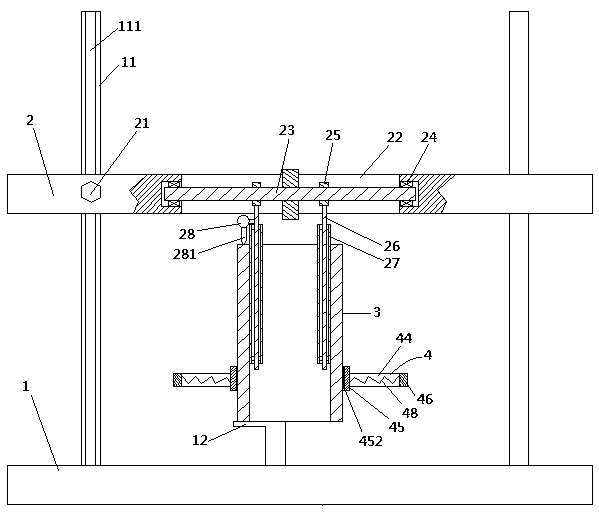

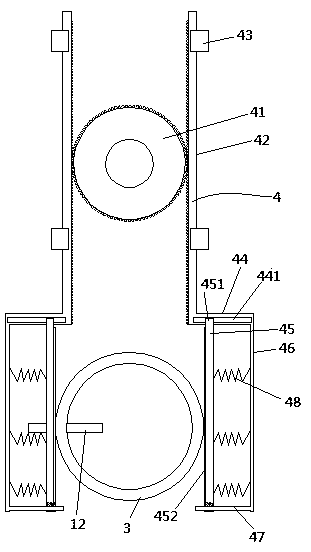

[0018] see figure 1 and figure 2 , a rubbing type detection device for measuring the levelness of the end surface of a circular pipe at both ends, comprising a panel 1, a lifting plate 2 and a rubbing type driving mechanism 4. At least two vertical sliding bars 11 are arranged on the panel. The upper end of the vertical slide bar 11 is pierced on the lifting plate. A locking groove 111 extending up and down is provided on the surface of a vertical slide bar. Lifting plate is threadedly connected with locking bolt 21. The locking bolt abuts against the locking groove to fix the lifting plate and the vertical slide bar together. A support rod 12 is fixedly connected to the panel. The supporting rod 12 is a round rod, so as to realize the line contact support to the lower end surface of the round pipe 3 and only support on one side of the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com