Shock wave combustion inducing ramjet and shock wave combustion inducing stamping starting method

A ramjet and shock wave technology, applied in ramjet engines, machines/engines, gas turbines, etc., can solve problems such as fuel and gas not being fully mixed and completely burned, affecting the propulsion performance of the engine, and increasing the structure of the engine, etc. Achieve the effect of improving propulsion performance, reducing weight, and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

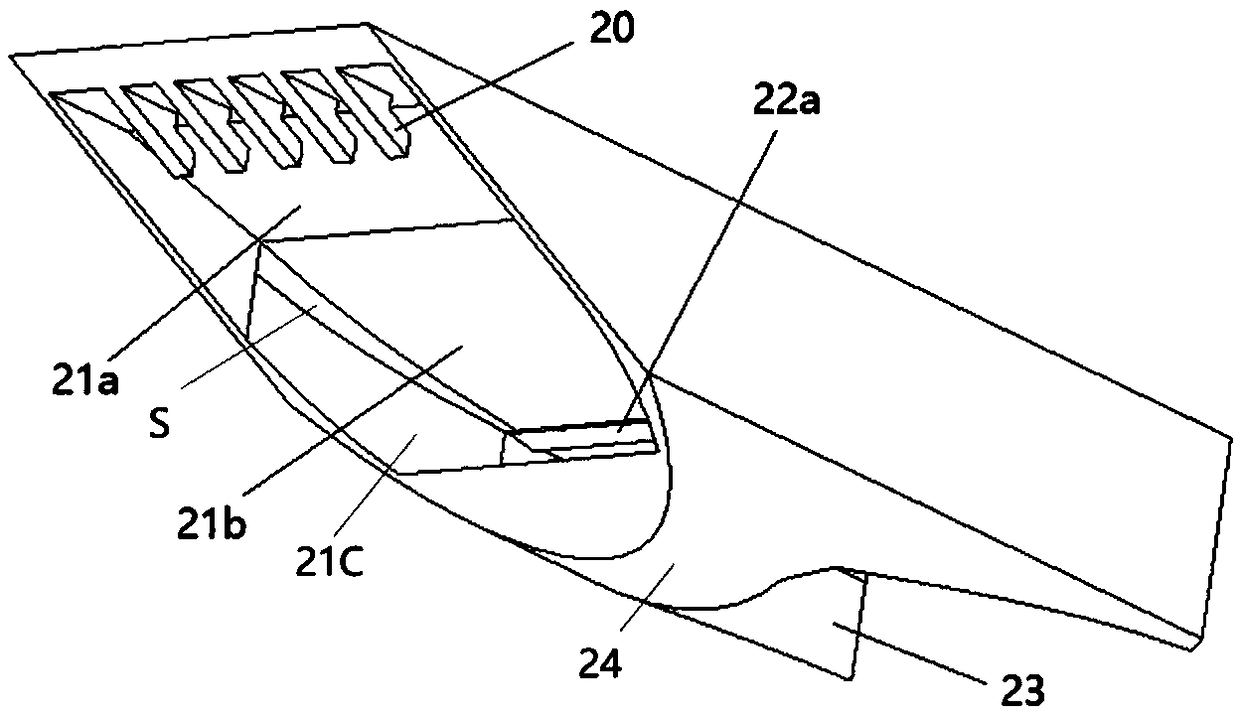

[0035] figure 2 It is a schematic diagram of the plane structure of a shock-induced ignition ramjet according to an embodiment of the present invention. The shock-induced-ignition ramjet engine includes: a fuel injector 20 , a three-dimensional lateral pressure intake port 21 with variable wedge surface, a combustion chamber 22 , and a tail nozzle 23 . A fuel injector 20 is arranged at the front end of the three-dimensional lateral pressure intake port 21 of the variable wedge surface. The variable wedge surface three-dimensional side pressure inlet 21 includes an upper wall surface and a side wall surface, and the upper wall surface includes a first wedge surface 21a and a second wedge surface 21b, wherein the slope of the second wedge surface 21b is greater than the slope of the first wedge surface 21a, The side wall is a retractable structure, and the side wall and the upper wall are connected by an arc transition.

[0036]Its working principle is that after the incoming...

Embodiment 2

[0040] image 3 It is a three-dimensional structure schematic diagram of a shock wave induction ramjet according to an embodiment of the present invention. Specifically, the engine is arranged at the bottom of the fuselage, adopting an integrated design of the fuselage and the engine. The intake port includes a fuel injector 20 at the front end of the intake port, a first wedge surface 21a on the upper wall of the intake port, a second wedge surface 21b on the upper wall of the intake port, and a bottom fairing 24 . At the entrance of the combustion chamber 22, two flame-stabilizing support plates 22a with inclined planes are arranged. Combustion flame for stabilizing gas mixtures. The tail nozzle 23 is a gradually expanding tail nozzle.

[0041] Figure 4 , Figure 5 and Figure 6 The sectional view, top view and front view of the shock wave induction ramjet are respectively shown. The side wall surface 21c of the intake port adopts a retracted design to realize the co...

Embodiment 3

[0046] In this embodiment, the shock wave induced ramjet method includes the following steps:

[0047] The upper wall surface of the air inlet is configured to have a first wedge surface and a second wedge surface, and the slope of the second wedge surface is greater than the slope of the first wedge surface; the side wall surface of the air inlet is configured as an inward structure; The side wall surface and the upper wall of the inlet port are configured as an arc surface transition connection; the fuel injector is arranged on the surface of the first wedge surface, wherein the fuel injector is a transverse array cantilever injector; optionally , the tail nozzle is configured as a gradually diverging structure; when the hypersonic incoming flow enters the intake port, the fuel injector injects fuel; the hypersonic incoming flow is compressed in the inlet section formed by the side wall surface and the first wedge surface, At the same time, it is mixed with fuel, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com