NbV composite microalloyed HRB400E steel bar and production process

A micro-alloying and production process technology, applied in the field of metallurgy, can solve the problems of high cost, inconspicuous yield platform, lower limit of the yield strength value of steel bars, etc., to achieve stable tensile strength performance, obvious and stable yield platform, cold bending Good effect of reverse bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

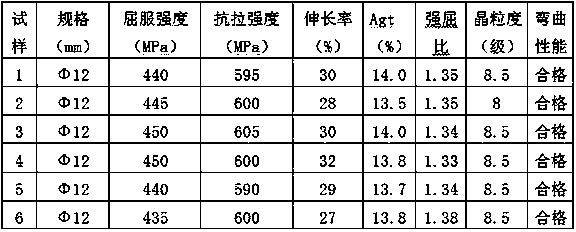

Examples

Embodiment 1

[0025] In this example, the specification of NbV composite microalloyed HRB400E steel bar is Φ12mm four-section steel bar, and its chemical composition and mass percentage are: C: 0.21%, Si: 0.35%, Mn: 1.36%, P: 0.028%, S : 0.015%, Nb: 0.018%, V: 0.012%, N: 64ppm, O: 43ppm, and the balance is Fe and unavoidable impurities.

[0026] The production technology of the present embodiment NbV composite microalloyed HRB400E steel bar comprises smelting, continuous casting, rolling process, and concrete process step is as follows:

[0027] (1) Smelting process: use top-bottom composite converter smelting, converter top-bottom blowing adopts nitrogen-argon switching process; converter deoxidation alloying, carburant uses 0.78kg / t steel petroleum coke, alloying uses 20kg / t steel Silicon manganese, 1.0kg / t steel ferrosilicon, 0.28kg / t steel FeNb60-B, 0.20kg / t steel FeV50-A, deoxidizer using 0.5kg / t steel silicon aluminum barium strontium; end point control using high Carbon drawing proc...

Embodiment 2

[0034] The specification of the NbV composite microalloyed HRB400E steel bar in this example is a Φ14mm three-section steel bar, and its chemical composition and mass percentage are: C: 0.20%, Si: 0.36%, Mn: 1.35%, P: 0.032%, S : 0.028%, Nb: 0.019%, V: 0.011%, N: 62ppm, O: 45ppm, and the balance is Fe and unavoidable impurities.

[0035] The production technology of the present embodiment NbV composite microalloyed HRB400E steel bar comprises smelting, continuous casting, rolling process, and concrete process step is as follows:

[0036] (1) Smelting process: use top-bottom compound converter smelting, converter top-bottom blowing adopts nitrogen-argon switching process; converter deoxidation alloying, carburant uses 0.70kg / t steel petroleum coke, alloying uses 20kg / t steel Silicon manganese, 1.0kg / t steel ferrosilicon, 0.30kg / t steel FeNb60-B, 0.18kg / t steel FeV50-A, deoxidizer using 0.8kg / t steel silicon aluminum barium strontium; end point control using high Carbon drawing...

Embodiment 3

[0043] The specification of the NbV composite microalloyed HRB400E steel bar in this example is a Φ16mm two-cut steel bar, and its chemical composition and mass percentage are: C: 0.21%, Si: 0.37%, Mn: 1.34%, P: 0.029%, S : 0.025%, Nb: 0.017%, V: 0.013%, N: 65ppm, O: 41ppm, and the balance is Fe and unavoidable impurities.

[0044] The production technology of the present embodiment NbV composite microalloyed HRB400E steel bar comprises smelting, continuous casting, rolling process, and concrete process step is as follows:

[0045] (1) Smelting process: use top-bottom compound converter smelting, converter top-bottom reblowing adopts nitrogen-argon switching process; converter deoxidation alloying, carburant uses 0.8kg / t steel petroleum coke, alloying uses 19.5kg / t steel silicon manganese, 1.1kg / t steel ferrosilicon, 0.27kg / t steel FeNb60-B, 0.22kg / t steel FeV50-A, deoxidizer uses 0.5kg / t steel silicon aluminum barium strontium; end point control adopts High carbon process, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com