Coal carbon slag decarburization method

A coal carbon slag and decarbonization technology, which is applied in the field of gasifier coal carbon slag, can solve the problems of unsatisfactory decarburization effect of slag and unsatisfactory decarburization effect, and achieve environmental protection, good decarbonization effect, and improved The effect of the decarburization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

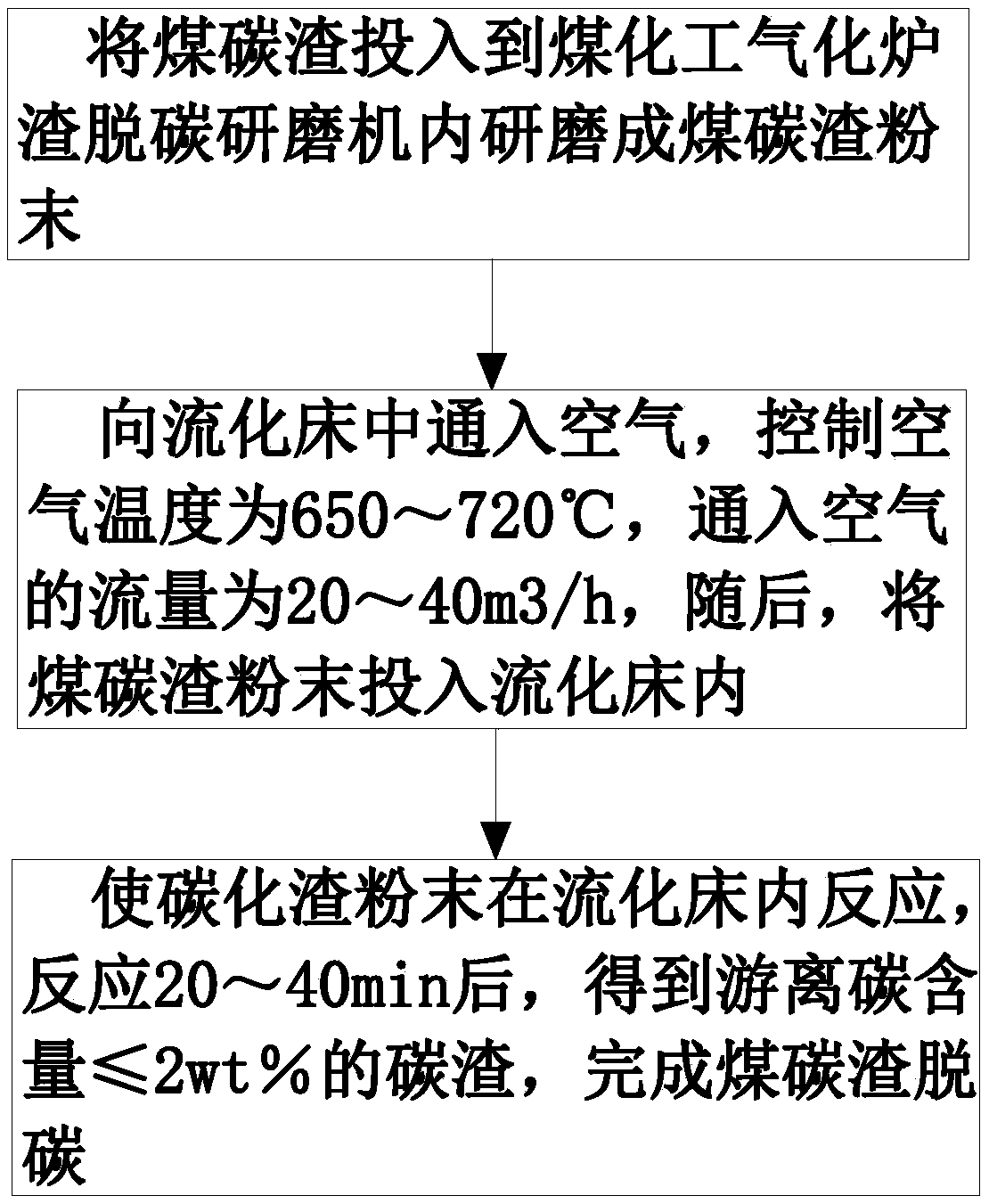

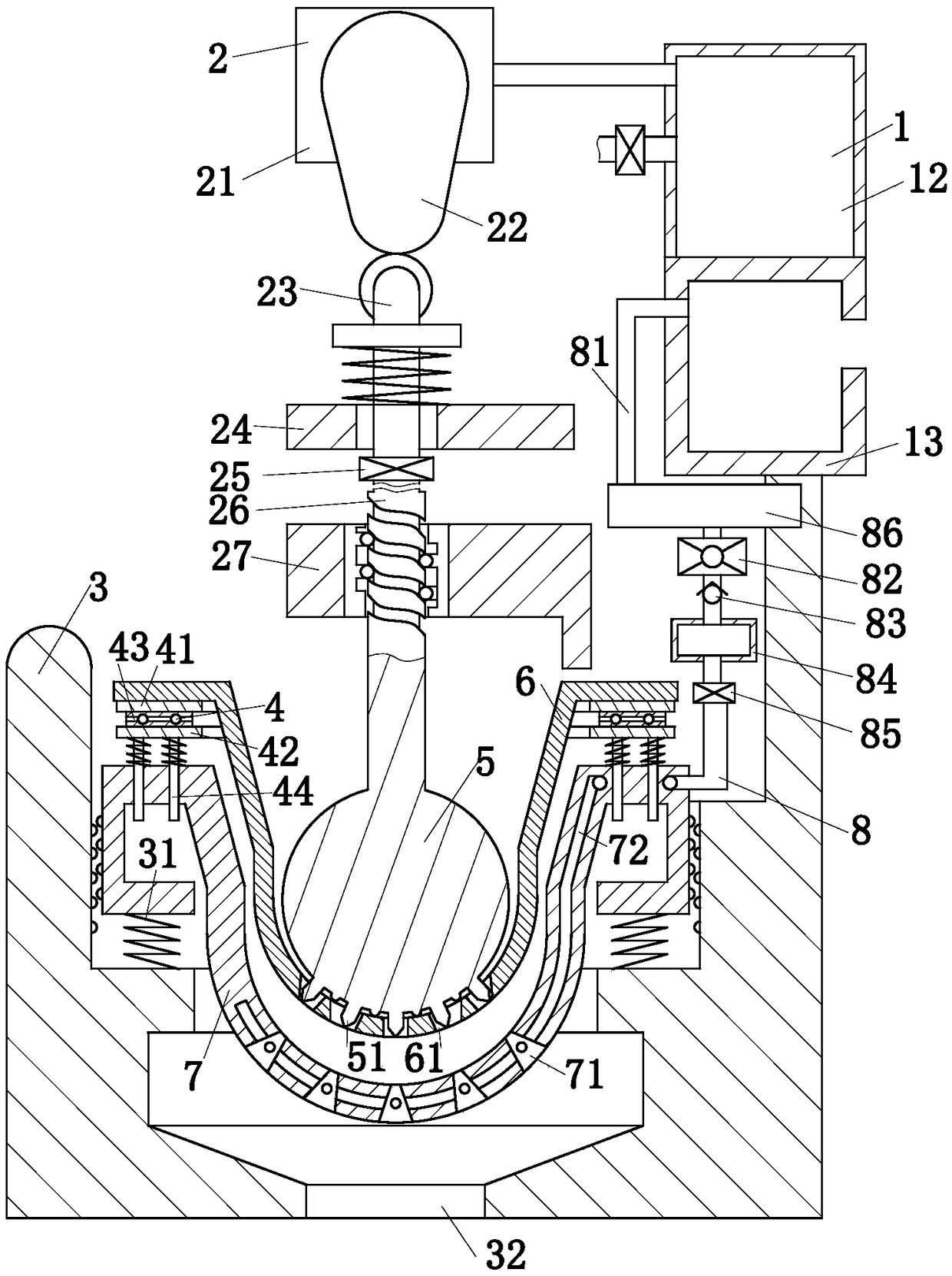

[0024] use Figure 1 to Figure 2 A coal slag decarburization method of the present invention is described as follows.

[0025] Such as figure 1 and figure 2 Shown, a kind of coal slag decarburization method of the present invention, this method comprises the steps:

[0026] Step 1: Put the coal slag into the coal chemical gasification furnace slag decarburization grinder and grind it into coal slag powder, and make the temperature of the coal slag powder higher than the ambient temperature, which can reduce the temperature in the subsequent fluidized bed from being lowered to reduce energy consumption;

[0027] Step 2: After the coal slag is ground into powder in step 1, air is introduced into the fluidized bed, the temperature of the air is controlled at 650-720°C, and the flow rate of the air is 20-40m 3 / h, subsequently, drop the coal carbon slag powder in the fluidized bed;

[0028] Step 3: After putting the coal carbon slag powder into the fluidized bed in step 2, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com