Solid waste treating and comprehensively utilizing method and system

A solid waste, one-way technology, applied in the direction of chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of increased safety, difficult solid waste treatment, pyrolysis gas recovery and utilization, etc., to achieve increased recovery, adaptability The effect of strong sex and huge market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

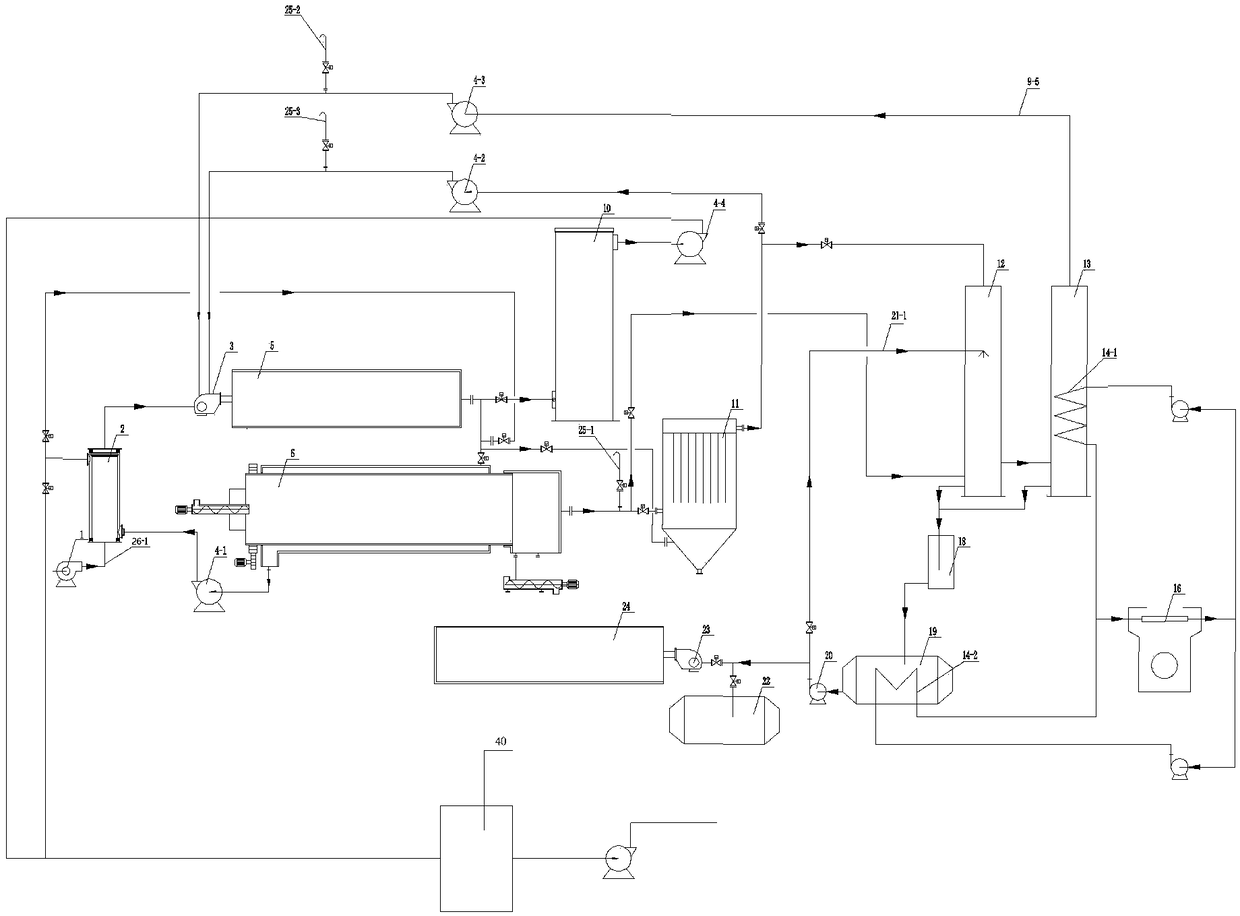

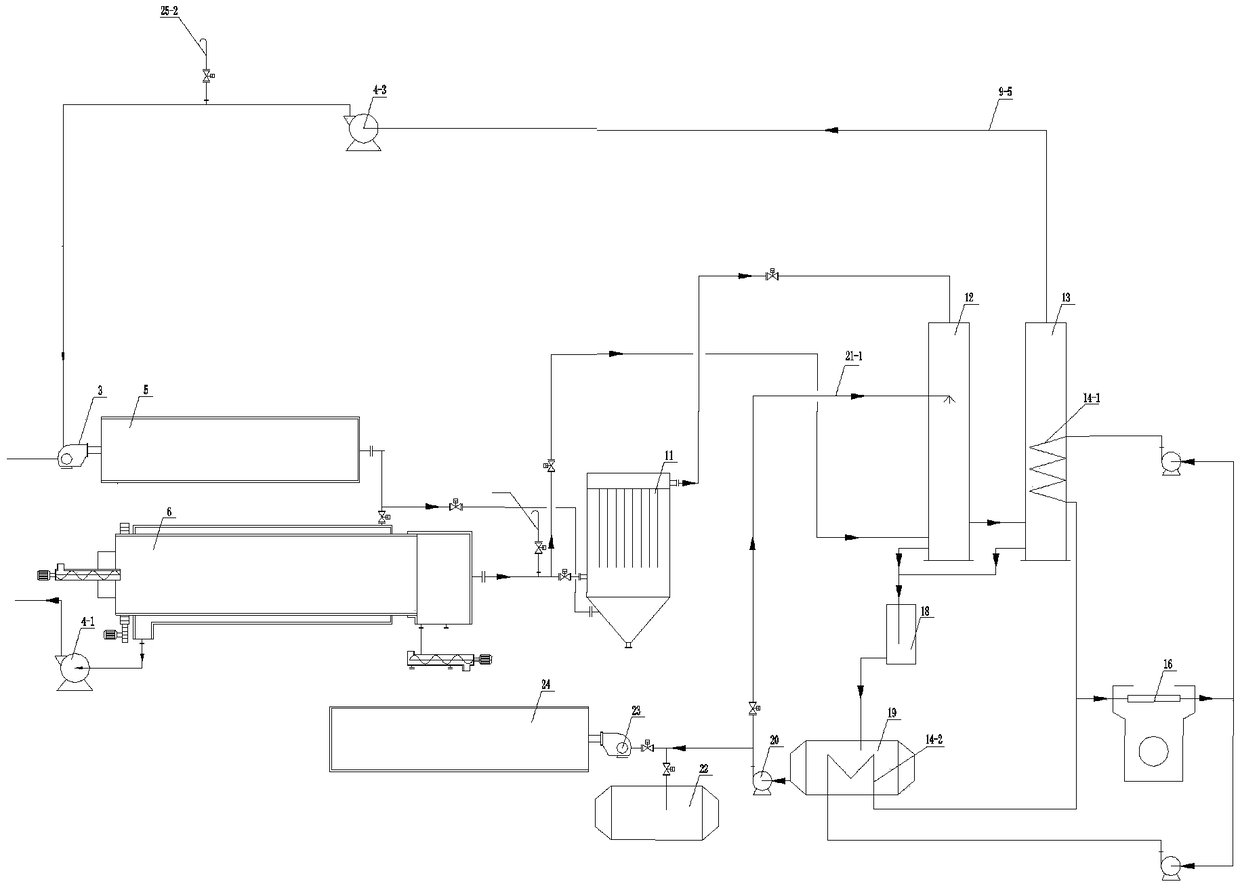

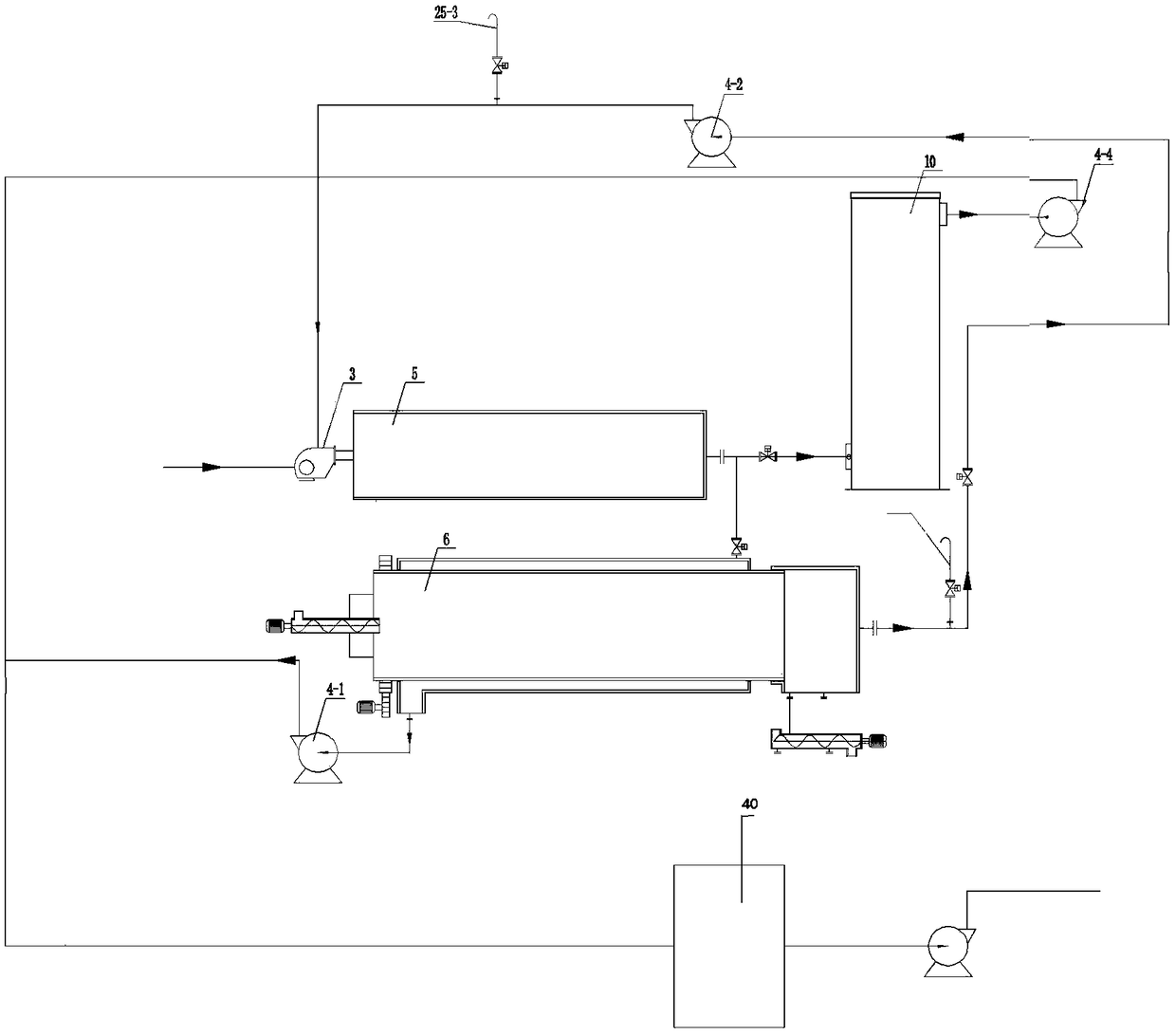

[0033] The pyrolysis system + waste heat recovery subsystem mainly includes a combustion chamber 5, a burner 3, a pyrolysis furnace 6, a feeding device installed at the entrance of the pyrolysis furnace, a slag removal device installed at the tail, and an exhaust fan 4-1. The pyrolysis gas outlet of the pyrolysis furnace 6 is connected to the inlet of the combustion chamber 5 through a pipeline, and the pyrolysis gas produced by pyrolysis is input into the combustion chamber 5 for combustion, providing the required heat source for pyrolysis for the pyrolysis furnace. The flue gas outlet of the combustion chamber 5 is divided into two through a pipeline, one pipeline is connected with the pyrolysis furnace, and the other pipeline is connected with the waste heat boiler, and the two pipelines are all provided with electric control valves. The main control system controls the flow of high-temperature flue gas entering the pyrolysis furnace by controlling the electronically control...

Embodiment 2

[0035] Pyrolysis system + oil recovery subsystem, when the pyrolysis gas contains a large amount of tar such as tar, if the complete combustion greatly exceeds the energy required for pyrolysis itself, it is necessary to increase the oil recovery device to recover the tar in the pyrolysis gas All or part of the recovery reduces the combustion value of the pyrolysis gas, and at the same time, a by-product can be added, which has great economic value. An oil recovery subsystem is added to the pyrolysis system, preferably using a two-stage oil condenser. The two-stage oil condenser includes a first oil condenser 12 and a second oil condenser 13. The pyrolysis gas outlet of the pyrolysis furnace is connected to the side gas inlet at the bottom of the first oil condenser 12 through a pipeline, and an electrical outlet is arranged in the middle. Control the valve, the pyrolysis gas enters the first oil condenser 12 from the side gas inlet, the top gas outlet at the top of the first ...

Embodiment 3

[0037] Pyrolysis system + filtration subsystem + oil recovery subsystem, compared with Example 2, the filtration subsystem is added, the reason is that the pyrolysis gas generated by the pyrolysis of some solid wastes contains a large amount of dust, if it will contain a large amount of dust If the pyrolysis gas is directly recovered by oil condensation, the resulting oil may also contain a large amount of dust. The equipment and pipelines through which the pyrolysis gas passes may accumulate a large amount of dust, causing pipeline blockage failures and potential safety hazards. Therefore it is necessary to increase the filtering operation to this type of application, and increase the filtering subsystem, add a pipeline to the filter from the pyrolysis gas outlet of the pyrolysis furnace, and the outlet of the filter is connected to the top of the first oil condenser 12 The top gas outlet, the filtered pyrolysis gas enters the first oil condenser 12 from the top inlet gas port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com