A graphene oxide/silver particle composite reinforced paraffin type phase-change energy storage material and a preparing method thereof

A technology for phase change materials and composite materials, which is applied in the field of solid-liquid composite phase change material preparation, can solve problems such as property limitations, and achieve the effects of improving affinity, enhancing thermal conductivity, and changing phase transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

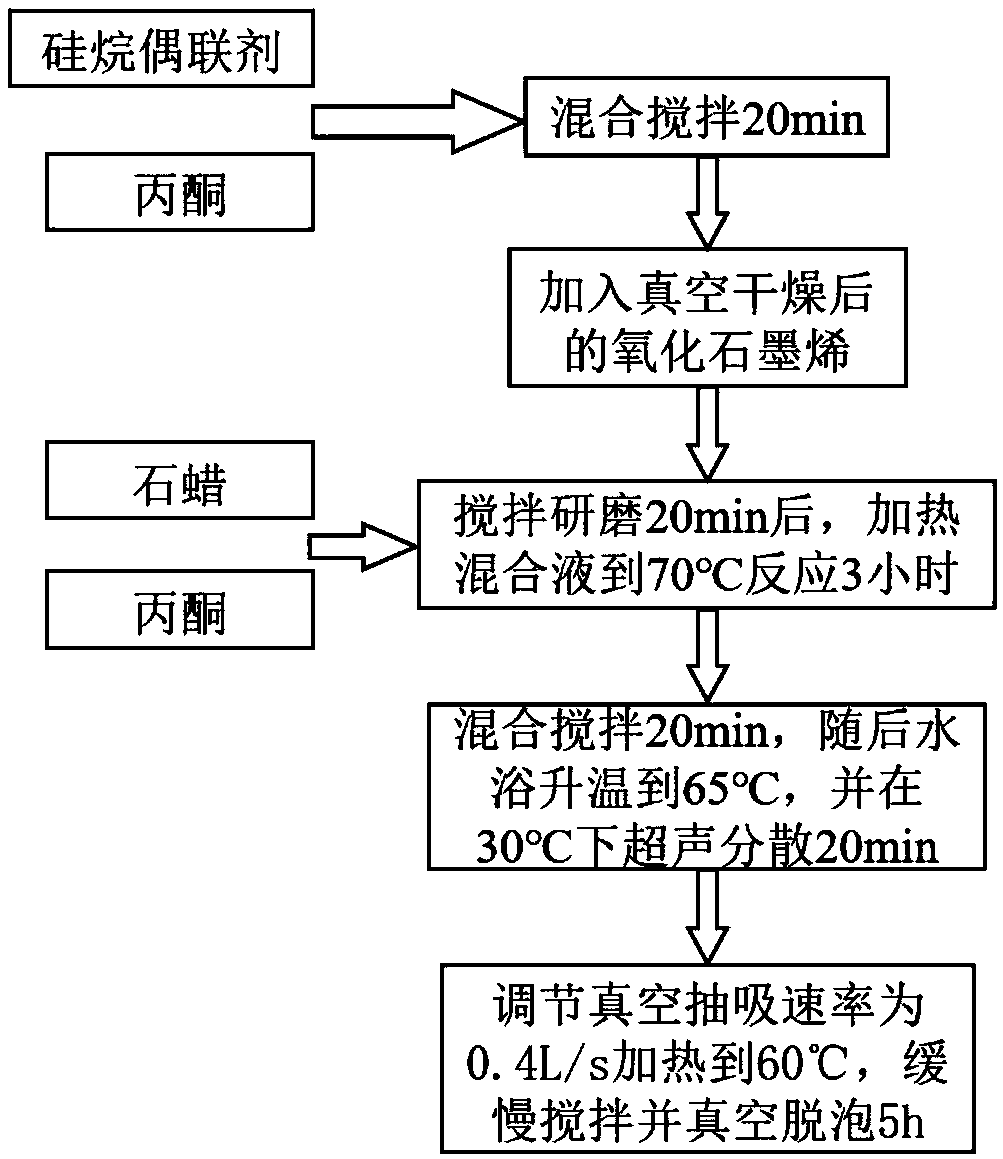

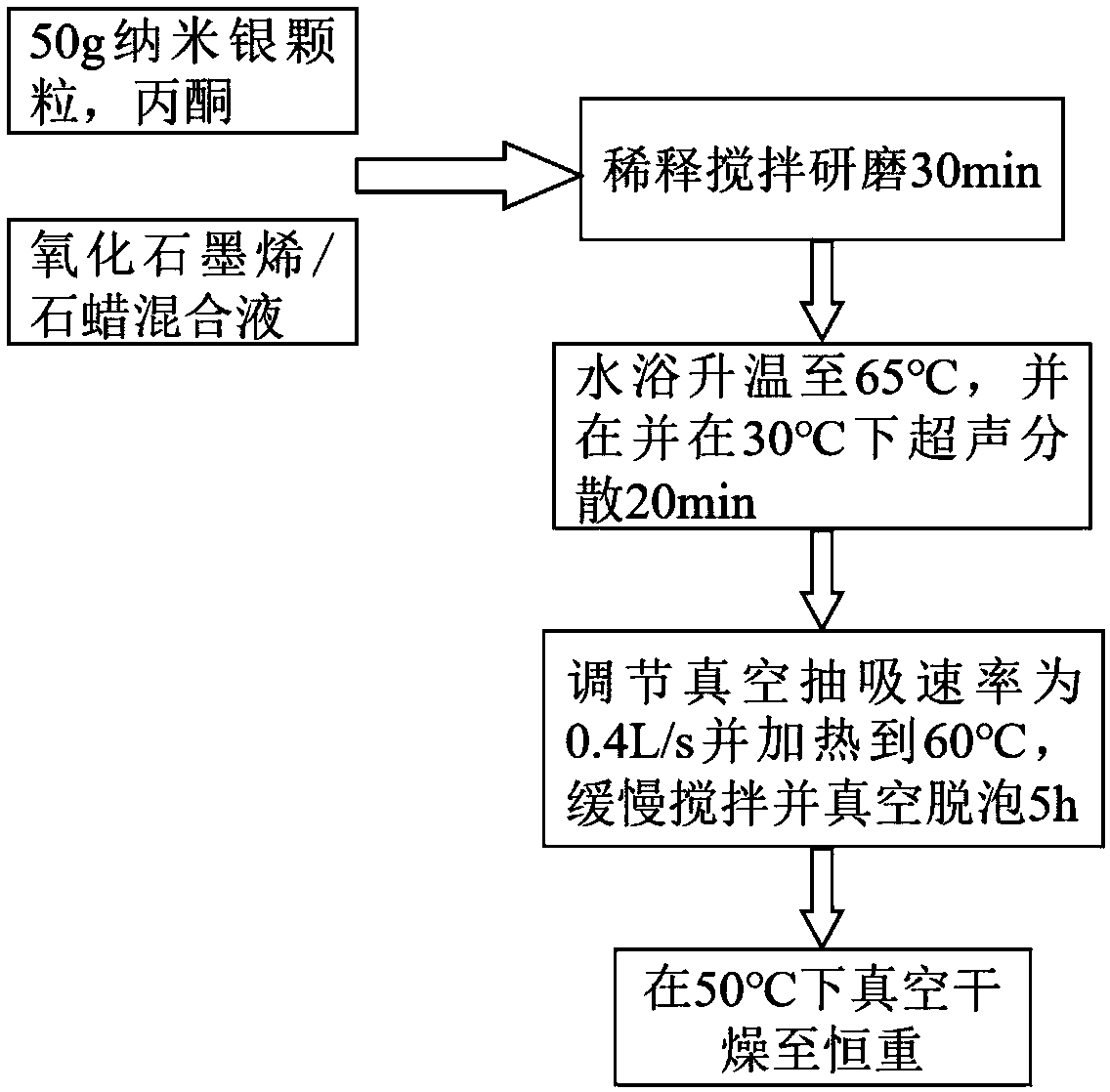

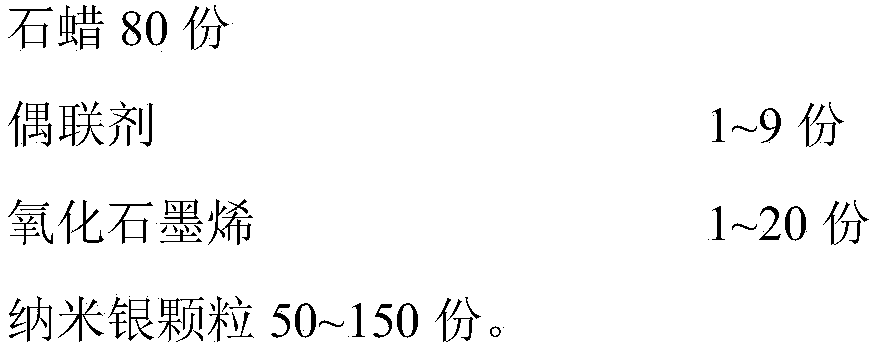

[0038] (1) In order to make graphene oxide better dispersed in paraffin matrix material, graphene oxide was modified by coupling agent. 5g of silane coupling agent KH-570 and 60g of acetone were mixed and stirred at 30°C for 20min; 10g of graphene oxide prepared by the improved Hummers method was vacuum-dried and added to the above mixture, stirred and ground for 20min; heated under vacuum The above-mentioned mixed solution was reacted at 70° C. for 3 hours to obtain a modified graphene oxide solution; 80 g of paraffin was chopped and added to the above-mentioned modified graphene oxide solution, and 100 g of acetone was added and mixed and stirred at 30° C. for 20 minutes; Heat the water bath of the above solution to 65°C, and ultrasonically disperse at 30°C for 20 minutes; put the above-mentioned ultrasonically dispersed mixture into a vacuum mixer, adjust the vacuum suction rate to 0.4L / s and heat to 60°C, and stir slowly And vacuum degassing for 5h to obtain the prepared g...

Embodiment 2

[0040] Example 2: The other conditions are the same as in Example 1, and the thermal properties of the materials produced by adding different amounts of silane coupling agent KH-570 are tested. The experimental results are shown in Table 1.

[0041] Table 1 Thermal properties of materials produced by adding different silane coupling agent KH-570

[0042]

[0043]From the above results, it can be seen that the addition amount of the silane coupling agent KH-570 is preferably 5 g (Example 1).

Embodiment 3

[0044] Example 3: Other conditions are the same as in Example 1, and the thermal properties of the materials produced by different graphene oxide additions are checked. The experimental results are shown in Table 2.

[0045] Table 2 Thermal properties of materials produced by different amounts of graphene oxide added

[0046]

[0047] From the above results, it can be seen that the added amount of graphene oxide is preferably 10 g (embodiment 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com