Surface wear-resistant coating used for wood sofa

A technology for wear-resistant coatings and sofas, which is applied in the production of coatings and bulk chemicals. It can solve the problems of affecting the appearance of wooden furniture, lack of pertinence, and poor wear resistance, so as to achieve good mental stress, improve mental stress, good storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

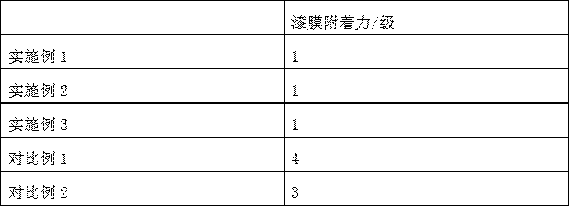

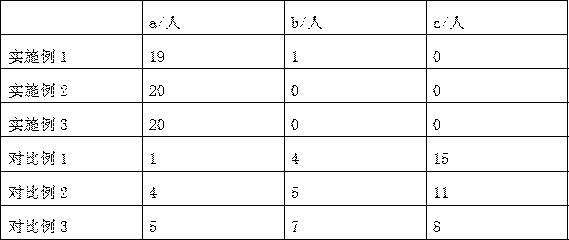

Examples

Embodiment 1

[0020] A surface wear-resistant coating for wooden sofas, which is made of the following components in parts by weight: acrylic emulsion 86, modified silicone rubber powder 5, inorganic nano fillers 4, wild lacquer leaves and water eggplant branch mixed extract 0.3, defoaming Agent 0.5, deionized water 60.

[0021] Further, the viscosity of the acrylic emulsion at 25° C. is 550 Pa·s.

[0022] Further, the inorganic nano filler is nano silica.

[0023] Further, the particle size of the nano-silica is 80 nm.

[0024] Further, the preparation method of the mixed extract of the wild lacquer leaves and the water stalks is: after the wild lacquer leaves and the water stalks are mixed in a mass ratio of 5:1, crushed, passed through an 80-mesh sieve, and then used hydrogen with a pH of 10.5 Soak the sodium oxide solution at 80°C for 40 minutes, then filter, rinse with clean water to neutrality, and drain naturally to obtain a mixture, and then add 10 times its mass to the mixture with an 80%...

Embodiment 2

[0034] A surface wear-resistant coating for wooden sofas, which is made of the following ingredients in parts by weight: acrylic emulsion 90, modified silicone rubber powder 8, inorganic nano filler 6, wild lacquer leaves and water eggplant branch mixed extract 0.5, defoaming Agent 0.8, deionized water 65.

[0035] Further, the viscosity of the acrylic emulsion at 25° C. is 550 Pa·s.

[0036] Further, the inorganic nano filler is nano silica.

[0037] Further, the particle size of the nano-silica is 80 nm.

[0038] Further, the preparation method of the mixed extract of the wild lacquer leaves and the water stalks is: after the wild lacquer leaves and the water stalks are mixed in a mass ratio of 5:1, crushed, passed through an 80-mesh sieve, and then used hydrogen with a pH of 10.5 Soak the sodium oxide solution at 80°C for 40 minutes, then filter, rinse with clean water to neutrality, and drain naturally to obtain a mixture, and then add 10 times its mass to the mixture with an 80%...

Embodiment 3

[0048] A surface wear-resistant coating for wooden sofas, which is made of the following ingredients in parts by weight: acrylic emulsion 88, modified silicone rubber powder 6, inorganic nano-filler 5, wild lacquer leaf and water eggplant branch mixed extract 0.4, defoaming Agent 0.6, deionized water 62.

[0049] Further, the viscosity of the acrylic emulsion at 25° C. is 550 Pa·s.

[0050] Further, the inorganic nano filler is nano silica.

[0051] Further, the particle size of the nano-silica is 80 nm.

[0052] Further, the preparation method of the mixed extract of the wild lacquer leaves and the water stalks is: after the wild lacquer leaves and the water stalks are mixed in a mass ratio of 5:1, crushed, passed through an 80-mesh sieve, and then used hydrogen with a pH of 10.5 Soak the sodium oxide solution at 80°C for 40 minutes, then filter, rinse with clean water to neutrality, and drain naturally to obtain a mixture, and then add 10 times its mass to the mixture with an 80% e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap