A kind of preparation method of polybutene-1 of narrow molecular weight distribution

A narrow molecular weight distribution, polybutene technology, applied in the field of preparation of polybutene-1, can solve the problems of conflicting research results, influence promotion, and inability to give influence rules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

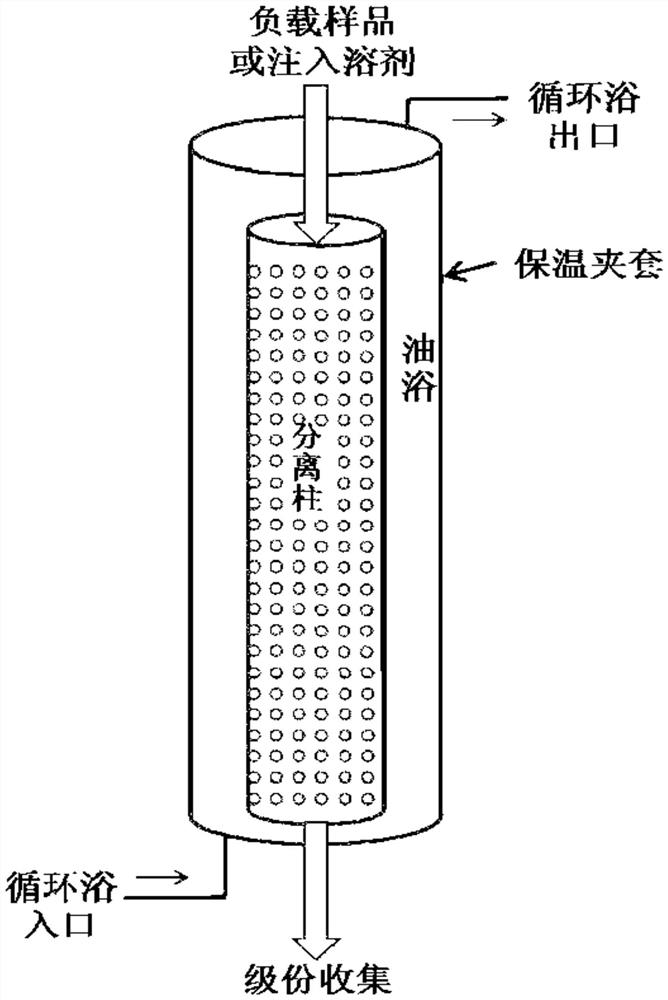

[0019] The invention provides a kind of preparation method of the polybutene-1 of narrow molecular weight distribution, comprises the following steps:

[0020] Dissolve the polybutene-1 sample in a mixed solvent at 120-150° C. to obtain a sample solution with a concentration of 0.5-1.5 wt %; the mixed solvent includes a good solvent and a poor solvent with a volume ratio of 70-95:5-30 Solvent; the good solvent is selected from one or more of 1,2,4-trimethylbenzene, 1,3,5-trimethylbenzene, 1,2,4-trichlorobenzene, dichlorobenzene and xylene; The poor solvent is selected from ethyl cellosolve and / or butyl cellosolve;

[0021] Lower the temperature of the sample solution to 10-30°C, load the sample on the filler, and completely replace the above-mentioned mixed solvent with a poor solvent after equilibrium, raise the temperature to 100-130°C, and then increase the volume percentage of the good solvent in order to balance After rinsing, polybutene-1 with a narrow molecular weight ...

Embodiment 1

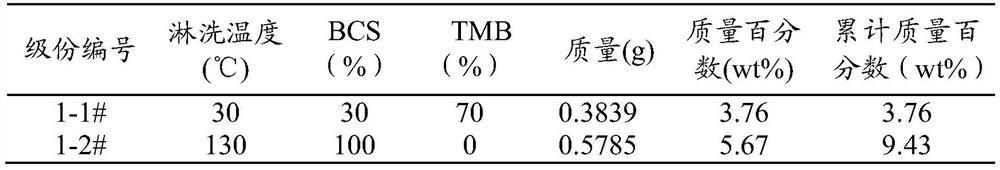

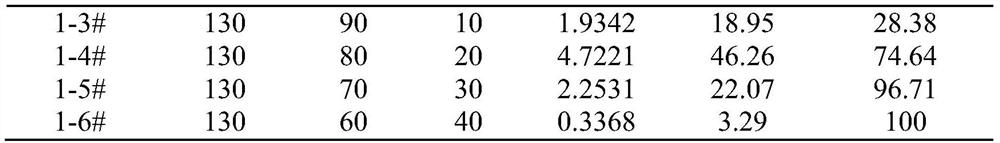

[0037] Solvent gradient fractionation PB-1 specific steps:

[0038] 1) Dissolve the sample: use 1,2,4-trimethylbenzene (TMB) as a good solvent and butyl cellosolve (BCS) as a poor solvent, and dissolve the resin in a mixed solvent of TMB:BCS=70:30 at a high temperature of 140°C For the sample, the solution concentration is 1.5wt%, and the dissolution time is 6h.

[0039] 2) Load the sample: transfer the sample solution to the fractionation column (filler is glass beads of 60-80 mesh), stabilize at 140°C for 60min, then cool down to room temperature at a constant cooling rate of 1.5°C / h, so that the polymer is separated from the mixed solvent The medium precipitate was loaded onto the glass beads packed in the column.

[0040] 3) Rinse the sample: After the cooling program is finished, after equilibrating at room temperature for 24 hours, replace the mixed solvent in the fractionating column with 100% poor solvent BCS, and elute out the room temperature fraction dissolved in t...

Embodiment 2

[0050] 1) Dissolving samples: 1,3,5-Trimethylbenzene (TMB) is used as a good solvent, and butyl cellosolve (BCS) is used as a poor solvent. Dissolve in a mixed solvent of TMB:BCS=80:20 at a high temperature of 140°C For the resin sample, the solution concentration is 1.0wt%, and the dissolution time is 4h.

[0051] 2) Loading the sample: transfer the sample solution to a grading column (filler is 60-80 mesh quartz sand), stabilize at 140°C for 30min, then cool down to room temperature at a cooling rate of 1°C / h, so that the polymer is removed from the mixed solvent The precipitate is loaded onto the silica sand packed in the column.

[0052] 3) Rinse the sample: After the cooling program ends, after equilibrating at room temperature for 24 hours, replace the mixed solvent in the fractionating column with 100% inferior solvent BCS, and simultaneously elute out the room temperature fraction (2-1 # grades). Then the fractionation temperature rises to 120°C, and by successively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com